The days of continuous improvement in analog/mixed-signal performance baselines for analog components are not over. In fact, remarkable strides are still being made in speed, precision, power consumption, and noise performance (see “ADC Makers Challenge Conventional Wisdom About SAR Speed And Resolution” at electronicdesign.com).

This file type includes high resolution graphics and schematics when applicable.

Yet the trend is toward embodying advanced electronics in complete solutions, rather than leaving system designers to create circuits from basic components. This works to the chipmaker’s advantage, since it accommodates a broader spectrum of circuit design skills. A junior engineer can be assigned to a project and still come up with an acceptable design in a reasonable amount of time and with less need for interaction with a senior engineer.

Indeed, in many cases, the approach taken by the semiconductor designer may require some special knowledge to realize performance that matches a part’s data sheet. Bundling a part with more support information than an application note—or hiding the more sensitive parts of the design in a complete reference design or inside an IC—yields faster time-to market for the chip company’s customer and builds brand loyalty.

There will always be application engineers. In fact, every year chipmakers send armies of them overseas to assist high-volume customers. (Domestic distributors have their own skilled apps engineers.) Beyond that, the Web offers greater opportunities for outreach, and the possibilities of proven reference designs, complete with layouts and bills of material (BOMs), to get the required information to the largest audience. The use of these tools is so widespread now that announcements about their release, their thoroughness, and the rationales behind their design appear nearly every week.

Company Support

Texas Instruments’ TI Designs reference design library spans the company’s entire portfolio of analog, embedded processor, and connectivity products for industrial, automotive, consumer, communications, and computing applications. Each design includes test data, a schematic or block diagram, BOM, and design files that help explain the circuit’s function and performance. Additional support material may include models, software, code examples, design guides, evaluation modules, and more.

Of course, this is in addition to the WEBENCH Design Center, which TI acquired with the purchase of National Semiconductor.2 WEBENCH provides unique and powerful software tools that deliver customized power, lighting, filtering, clocking, and sensing designs in seconds. Furthermore, the company’s TI E2E online community connects more than 120,000 engineers with TI product designers and application engineers and with each other. It provides live and on-demand training, including videos, seminars, webcasts, workshops, and conferences.

On December 6, the Society for New Communications Research awarded the Analog Devices EngineerZone online technical support community (ez.analog.com) its Commendation of Excellence. Analog Devices first launched EngineerZone in 2009 as a global design resource that serves engineers across the semiconductor signal processing chain.

Also, Analog Devices’ Circuits from the Lab offers more than 200 designed and tested solutions for process control, instrumentation, communications, healthcare, automotive, and motor control, with complete documentation and test data.3 The latest circuits include schematics, BOMs, layout files, low-cost evaluation boards, and device drivers when applicable.

In November, Maxim Integrated launched its Carmel, Monterey, and Fremont reference designs. These fully tested subsystems come complete with schematics, layout files, and firmware. They’re all available for immediate use and customization. Each integrates multiple functions for an automated factory task. According to the company, they also facilitate rapid prototyping, early software development, and speed of design.

The Carmel (MAXREFDES18#) provides high-accuracy, low-noise analog signals suitable for input to programmable logic controllers (PLCs) and distributed control systems (DCSs). It features accurate output from high voltages down to true zero, integrated error reporting, and detection of short circuit, open circuit, brownout, and over-temperature conditions. It also provides both current and voltage outputs, including bipolar signals of –20 to 20 mA and –10 to 10 V.

The Monterey (MAXREFDES15#) high-accuracy, industrial, loop-powered sensor transmitter converts a standard temperature sensor input (RTD PT1000) to a 4- to 20-mA signal that is immune to noise and constant over long distances. System current consumption is less than 2.1 mA, which is a 40% improvement compared to the industry standard. It supports 0.1% system accuracy over a full process variable-input range.

The Fremont (MAXREFDES6#) low-power analog front end (AFE) accepts inputs of 0 to 100 mV. It is intended for low-voltage output sensors and for process control and medical applications. It is characterized by low-power operation (less than 300 mW typical), fast prototyping with all necessary design files included with the reference design, and simplicity as the single-ended system eliminates the need to convert to differential signals.

Recent Products

Even more than Web sites and reference designs, new products illustrate trends in functional integration and product performance. Again, the trend is toward system solutions. For example, the Texas Instruments LDC1000 position sensor (Fig. 1) goes beyond mere Hall effect sensing to open new possibilities in automotive, medical, and general industrial applications (see “Inductance-To-Digital Converter Offers Breaktrhough Sensing Performance” at electronicdesign.com).

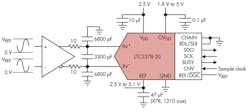

Meanwhile, Linear Technology has always fought to own the highest ground in terms of fundamental performance measures. Its 20-bit, 1-Msample/s, no-latency LTC2378-20-1 successive approximation register (SAR) analog-to-digital converter (ADC) boasts a typical integral nonlinearity (INL) of 0.5 ppm and a guaranteed maximum no greater than 2 ppm (Fig. 2). Its signal-to-noise ratio (SNR) is 104 dB, and its guaranteed maximum total harmonic distortion (THD) is –114 dB from –40°C to 85°C.

According to Linear, the LTC2378-20-1’s wide dynamic range and true 20-bit resolution reduce or eliminate the need for additional gain in the signal chain, improving total system accuracy and noise. With its fast 1-Msample/s throughput and no latency, it enables the use of multiplexers to replace costly, independent ADCs with slower throughputs to reduce system cost and complexity.

Over the past year, Maxim Integrated has refocused on developing very high-performance discrete devices that will serve as cores for the highest-performing ASICs, as indicated by the Carmel, Monterey, and Fremont reference designs. Also, Maxim’s precise, drop-in-ready Cupertino (MAXREFDES5#) isolated 16-bit AFE subsystem reference design targets industrial sensors, process control, and PLCs.

With analog –10- to 10-V, 0- to 10-V, and 4- to 20-mA inputs, the Cupertino supports all of the common industrial sensor analog outputs. Maxim provides all of the hardware design files, example driver code, and test results needed to speed design development. Its AFE connects directly to FPGA/CPU development kit expansion ports that conform to Diligent’s Pmod standard.

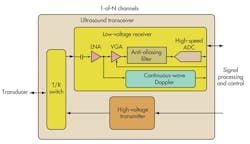

Maxim’s highly integrated MAX2082 octal ultrasound transceiver integrates eight channels of three-level, 200-V pulsers and T/R switches, an octal ADC, an octal low-noise amplifier (LNA), an octal variable gain amplifier (VGA), continuous-wave mixers (for Doppler), anti-aliasing filters, and coupling capacitors into a package small enough to enable an entire 128-channel solution in less than 10 square inches (Fig. 3). Traditional designs include more than nine components in the T/R switch alone for each channel on a typical 128-channel system, so the MAX2082 displaces thousands of discrete parts.

Last February, Intersil and Freescale jointly announced a thermocouple/strain gauge demo board that combines Intersil’s precision and power products with Freescale’s Kinetis L series microcontroller, with a Cortex M0+ core on one board and Freescale’s FRDM-KL25Z Freedom development platform on the other.

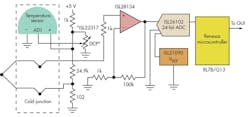

The thermocouple design uses a K-type thermocouple with cold junction compensation, Intersil’s ISL28134 zero-drift amplifier, ISL21090 voltage reference, ISL22317 DCP, and ISL26102 24-bit delta-sigma converter. The Freescale board includes the Freescale KL25Z MCU plus 128 kbytes of flash and 16 kbytes of SRAM.

The thermocouple temperature or applied strain can be monitored using a GUI on the computer powering the demo through the mini USB cable. The display shows real-time data in either a numerical or a graphical representation of the temperature or strain measurement.

Diversifying its relationships with controller companies, Intersil accompanied the Freescale announcement with another, highlighting its “DAQ (data acquisition) on a stick” series of USB drives, which include complete reference designs and sets of self-contained demonstrations. For example, one stick offers practical sensor solutions for thermocouple, pressure, and strain gauges, using a Renesas RL78 to process analog and digital signals (Fig. 4).

About the Author

Don Tuite

Don Tuite (retired) writes about Analog and Power issues for Electronic Design’s magazine and website. He has a BSEE and an M.S in Technical Communication, and has worked for companies in aerospace, broadcasting, test equipment, semiconductors, publishing, and media relations, focusing on developing insights that link technology, business, and communications. Don is also a ham radio operator (NR7X), private pilot, and motorcycle rider, and he’s not half bad on the 5-string banjo.