Download this article in PDF format.

Carl Nelson is an analog IC designer. He consults at Linear Technology, which was recently acquired by Analog Devices. Bob Dobkin, Linear Tech co-founder and CTO, notes, "Carl is the best, most inventive engineer I have ever worked with."

Nelson has participated in many well-known designs, including the world's most precise IC voltage reference, the LTZ1000. He holds 44 patents. When I asked Nelson about a plaque I remembered in the LTC lobby that listed his patents, he replied, “Yeah, it was a little embarrassing, but it did make me smile when I walked into work every day.” Nelson is considered one of the “analog gurus” at Linear Tech/Analog Devices.

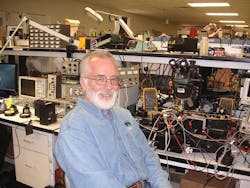

While many have heard of the flamboyant analog engineers like Bob Widlar or Bob Pease, Nelson comes from a second generation of experts that let their work speak for itself. Nelson does remarkable designs in a quiet and unassuming way. Upon finding a nice picture I took of him in 2011 at his lab bench at Linear Technology (Fig. 1), I emailed him some questions about his life and his work.

1 Analog IC designer Carl Nelson at his lab bench at Linear Technology in 2011. The microscope is part of a probe station that lets Nelson test his IC die.

Where did you you grow up?

Homer, Alaska. It is the end of the road if you start at the tip of South America and drive north. There used to be a sign coming into town that said “Homer, Alaska—End of the Road.” Now it says, “Homer, Alaska, Halibut Fishing Capital of the World.” Every summer the fishing derby winner tops out at over 300 pounds. It was a great place to grow up—nobody locked their doors.

Were you a prodigy who had a crystal radio when you were 12 years old?

I built an AM radio from a kit at age 10. It didn’t work at first. That taught me a valuable lesson about attention to detail. It was a tube radio that used “termination strips” for connection points. They came in various lengths, and there were several “5 tab” units in the design. Turns out that one version had pin 2 grounded and one had pin 3 grounded, but the assembly instructions failed to mention that. The electronic technician at my dad’s work finally figured it out. I loved that radio—it had lots of glowing parts, and I still have it. I would listen to broadcasts out of San Francisco, and dream about California.

Did you get a formal education or learn more by the seat of your pants, like Jim Williams and Linear Tech CTO Bob Dobkin?

I received a Bachelor of Science in Electronics Engineering from Northrup Institute of Technology. I almost got expelled after I wrote a scathing review of one of the electronics lab projects. The official setup used equipment that couldn’t possible give the desired results. Almost everyone in the class either faked their reports to come out “right,” or showed the wrong results with no explanation. I figured out what was wrong and wrote an extended report about it, along with comments about faculty blowing off the faking issue. The dean was unhappy to say the least. That taught me two very important things about life. Always trust your gut when things seem not quite right or too good to be true, and never trust authority.

I graduated at the upper part of my class, but all I could think about was, “I don’t know crap, what am I going to do if someone gives me a job?” I do remember telling college classmates that in high school I made an oscilloscope out of a Mason jar and surplus FAA radio equipment. I was amazed when they seemed to believe me.

What got you into engineering, and what got you into analog IC design? What companies have you worked for?

Early on, I wanted to be either a doctor or a physicist. I finally decided I didn’t have the heart for medicine, or the cajones for high-level physics, so electronics seemed the next choice. I had built an AM radio, and I was fascinated by the room full of glowing tubes where my father worked at the FAA flight control center (CAA in those days). I went to work for Continental Device Corporation in Los Angeles after college, supporting their semiconductor lab work. My first project was a 30,000-V aluminum deposition machine, so I’m lucky to still be alive.

A vivid early memory is walking down the hall outside the lab carrying a Dewar of liquid nitrogen. I was passing a lab tech. He said, “Whatcha got there?” and plunged his fist into the Dewar. I froze (pun intended), and probably got white as a sheet. He laughed and jerked his hand out immediately, shook it off, and continued to walk down the hall, proclaiming “Takes a few seconds to freeze.”

Continental was a diode/transistor company that had decided to get into the fledgling analog IC business. I asked to be part of the design team, and got in. It was purchased by Teledyne and I moved north to Sunnyvale. Several years later, Bob Dobkin called from National Semiconductor and asked if I wanted to work with him and Bob Widlar. I never looked back.

Over 10 years later, Dobkin, Bob Swanson, and others left to start Linear Technology. I got Dobkin’s old job at National Semiconductor. After a few months, it became obvious that National was shifting emphasis from analog to digital, so I joined Linear Technology. I have badge #11. I would have gotten a single-digit badge, but I took a two-week vacation before signing the paperwork.

Who were your big influences, not only for engineering, but life in general?

My dad taught me about how much gets done when you avoid relaxing. My mom showed me that the Golden Rule is definitely the way to go. I was fascinated by Einstein’s early work history and Richard Feynman’s blending of brilliance and antics. I read science fiction constantly from age 7 to 17. Arthur C. Clarke's Childhoods End made me see what a narrow slice of history is occupied by the human race, and what the possibilities might be for the future.

From the time I was in high school, it was apparent that most things came easy for me, with music and foreign language as notable exceptions. For a while I had an inflated ego problem. The school administration flatly rejected the speech I wrote as salutatorian, since it made fun of nearly all the treasured American traditions. Then I began to realize that my good fortune came to me purely from genetics and luck. I resolved to eat a little humble pie and figure out how to make good use of what I’d been given.

What was your favorite design project?

The LM35 temperature sensor at National Semiconductor. The idea is you turn a bandgap reference inside out, and trim it correctly at room temperature. Then you have a temperature sensor that was inherently accurate across all temperatures. When the math proved me right, I was about as excited as an engineer can get. The patent for this concept stands out in my mind above all my others.

What was the toughest technical challenge you faced and solved?

I’m still working on it (Fig. 2). It started back at National Semiconductor when we wanted to make a very stable Zener-based reference. The NPN emitter-base junctions were sensitive to surface charge conditions and moved around with time. Dobkin and I decided to see if we could make a buried Zener structure. The first attempt was orders of magnitude better than anything else we had seen. That spawned Dobkin's LM399, a heated reference with very low drift and great long-term stability.

2. Carl Nelson uses his pool table as a handy platform to stretch out plots of his IC designs.

Ten years later, we began thinking about how to take the next step toward “God’s own reference.” We made the decision to design a heated chip that had only the basic reference parts on it, comprising a Zener diode, a temperature-compensating transistor, a temperature-sensing transistor, and a heater. That way, we could optimize the layout to be sure all the devices were at exactly the same temperature, even with the heater running at full power. The user could crank up the Zener diode current to get extremely low noise. That became the LTZ1000, and it was the only game in town for very high-end DVMs (digital voltmeters) and NIST (National Institute of Standards and Technology) transfer standards. I have heard scientists used it to calibrate the Large Hadron Collider. Yet even that part has drift and noise residues. The goal is to make a part so good that you can’t measure it, so the work goes on.

Does a good analog IC designer ever have to look for work, or is there constant demand?

Companies are nervous about hiring analog designers, because it is very difficult to separate the good and bad ones in an interview. Early on at LTC, we only hired by word-of-mouth for engineers with an established track record of shipping designs. Good designers may have to kiss a few frogs early in their career, but after that, they can move around pretty freely and ask for a piece of the pie. I do frown on hiring someone who has moved around a lot, though. It’s often indicative of a lack of dedication to the art.

In the old days, making good parts with manufacturing processes that were still evolving was a challenge for IC designers. Has modern process control made your job easier or tougher?

I “retired” 20 years ago and didn’t do any true design work for 10 years. When I tried my hand again, I was amazed at the process improvement during that 10-year period. Processes were ion-implanted, with big improvements in performance, size reduction, variability, and reliability. Wafer yields increased from 60-80% to over 90%. I consulted for Touchstone Semiconductor briefly. Their business model depended on wafer yields being so high that wafer sorting was just skipped and the die went straight to assembly.

All these process improvements came at a cost. The original analog processes used 6 to 8 mask steps. The new, simple ones use 15 mask steps. The high-performance ones use 30 or more. The long process time and high mask costs puts big restraints on the number of acceptable design changes to get a part right. In my opinion, some companies make too many “close enough, ship it” decisions these days. The good news is that modern Spice simulations and automatic mask error checking are so good that there are very few unintentional errors.

The trick is to be very, very good at asking Spice all the right questions before you finalize the design. One area that has not been changed by computation and automation relates to the details of chip layout. Unlike digital chips, device position matters with analog. It’s not only because of thermal gradients, but more arcane things like stress, thermocouples, and matching. After a long stressful design process, it’s hard to spend many more days or weeks poring over details of chip layout. Yet if you don’t, Murphy’s Law will bite your ass. Moving the devices later on means all new masks, big delays, and unhappy managers.

Do analog designers have to work hand-in-hand with process engineers?

Some design engineers just take what they get from the fab group. I always looked for ways to get better devices. The fab guys weren’t exactly happy to see me coming, but I always made sure what I asked for was practical in production. The mask design group finally hung up a sign that read, “Rules are made to be broken, signed, Carl Nelson."

Do you use Spice simulations and do you trust them?

I depend totally on Spice now, and by itself, it’s rarely let me down, except for convergence problems, which I work around. What does get a little iffy are the models. When a company contracted me to do several circuits for them, I picked up half-a-dozen serious errors in the models for a 10-year-old process. Modeling is hard when the engineers are always pushing the boundaries of what can be done with silicon.

When I designed a 1-ppm bandgap voltage reference, we discovered a 1- to 2-ppm cubic bow error that was impossible to reproduce with existing bipolar models. We finally gave up and fixed the problem with a couple of breakpoints. We still have no idea where the cubic error comes from, so we hope it stays constant in production.

Jim Williams told me that designing the test regime for a new IC can be just as extensive and time-consuming as the IC design itself. Has that ever been your experience?

I agree with Jim. When I did the 1-ppm reference, I told the product and test engineers that they probably wouldn’t be able to measure it in a high-speed production environment. The line regulation is 0.2 ppm/V, and the load reg is 2 µV/mA. Those numbers are buried in the noise, and this is a low-noise part. The numbers are so small that they often fall on both sides of zero. That means you won’t know when the test system breaks because zero has to be an acceptable answer. With a 1-ppm drift spec, they needed to be able to measure drift to 0.05 ppm/°C accuracy to minimize yield loss.

The test group decided to use the HP 3458A 8 1/2 digit voltmeter, which uses the LTZ1000, coupled to a D-to-A converter and low-noise filtered preamps to pull the signal out of the mud. Even with that, some of the specs are sandbagged on the datasheet to reflect the test problems. There is a drift spec of 1.5 ppm, for instance, instead of 1 ppm.

I have heard that amongst analog IC designers, "there are bipolar folks, and there are CMOS folks, but never both." Are there really two camps, or do designers do both? Which are you?

That used to be a truism, but not anymore. Modern analog processes have great devices, both bipolar and CMOS. If a designer can’t use both effectively, he is at a serious disadvantage. I am basically a bipolar guy, but during my retirement, I invested in a startup that was doing MEMS switch arrays for fingerprint recognition. They had a serious problem with signal levels while trying to read the array, and their supply current was a factor of 10 higher than they wanted.

I had an epiphany one day. I realized there was a totally different way to activate and read the array, which solved their problems. This needed a custom CMOS reset amplifier made on the MEMS process. I cobbled together a design using CMOS models from Google to prove the concept worked, even though I had never done a CMOS circuit before. The company was very grateful, and insisted on compensating me in some way. I looked in my Wines of the World book and picked a case of Chateau Mouton Rothschild that was selling for $80 a bottle. What I didn’t know was that the wine had exploded in price since the book was published.

A week later a truck marked Bordeaux Express pulled up to my house and unloaded a crate of wine. When I invited some knowledgeable friends over to eat and drink, one of them asked, “Do you have any idea what this stuff costs?” I looked on Google, and almost had a heart attack. The moral of the story is that CMOS pays well. I had no trouble getting friends over for the next year.

When I wrote, you mentioned you live in Alaska, and that the bears were ransacking the neighborhood. What brought you to Alaska, and what type of home and lifestyle do you enjoy up there? Has the bear threat subsided?

3. Carl Nelson and his wife Sheryl live in a home she designed in Anchorage Alaska.

I live in both the Willow Glen neighborhood of San Jose, California and Anchorage, Alaska (Fig. 3). After I retired, I was bored, so I started a website that made it easier for my high school classmates to find each other. There was a girl named Sheryl that I dated in high school and couldn’t find. Six months later she found out what I was doing and sent a simple email: “Hi Carl, life is good.” She was living in Anchorage and had been an architect, a model, and a race car driver. Twelve-hundred emails later I went up to Anchorage and it was like we were back in high school.

She found a house for sale that she had designed that was big enough for a wine cellar, a pool table, and lots of guests. She designed me a big woodworking shop that was added on to the house, and life was complete. We found out after her mother died that mom had confiscated my letters from college, so we lost a lot of years.

4. Alaska is still a wild frontier. Bears roam the neighborhoods where Carl Nelson takes up residence.

Bears are a big problem this year (Fig. 4). Three or four people have died in the Anchorage area alone this summer. Sheryl owns a .357 Magnum pistol if needed. Yet there are no snakes, no deadly spiders, no ticks, no fleas, no mosquito-borne illnesses, and no deadly weather. Just the occasional earthquake, like California. Restaurants in town are second to none, including the wine lists.

I kept my restored Victorian house in Willow Glen (Fig. 5), and that town really upgraded itself during my 35 years there. We walk out the front door, and in five minutes, walk into any one of a dozen good restaurants, many with sidewalk seating, reminiscent of Paris.

5. When Carl Nelson moved back to his native Alaska to be with his high-school sweetheart, he kept the home he restored in the Willow Glen neighborhood of San Jose, Calif.

You once told me you love woodworking. What kind of projects do you do?

I mentioned that Sheryl designed me a custom wood shop, about 800 ft.2 (Fig. 6). It has full dust collection, a garage-style door to get big things in and out, and lots of nice toys. There’s a scaled-down version in the basement under my house in Willow Glen. I spent 30 years restoring that Grand Old Lady. I do a bit of everything, from furniture and cabinets to decks and sidewalks.

6. Carl Nelson enjoys the wood shop attached to his house in Anchorage. Analog engineers often have many passions.

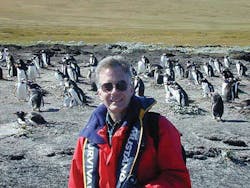

Are there other interests that occupy your time; travel, sports, music, photography, etc.?

I do like to travel, so I’ve seen lots of Europe, the South Pacific Islands, Australia and New Zealand, Japan, Hong Kong, Singapore, Bali, parts of South America, Galapagos, Antarctica, and Canada (Fig. 7). A few years ago, we drove the East Coast, from Florida into Canada, and I finally got to see Niagara Falls, where my parents went on their second honeymoon. Next summer we go to the Dominican Republic for my granddaughter’s wedding.

7. In addition to his other interests, travel has taken Carl Nelson to places like Antarctica, surrounded by thousands of docile penguins.

Lately I’ve been learning PC board design, so I can build stuff for fun. I found a fab house that will do smaller boards for $33 each even in small quantities. My latest project is a thermocouple amplifier that corrects Type K thermocouple nonlinearity from 15°C to about 0.4°C over a −100°C to +1200°C range. I will use the analog output to run reference drift tests automatically in my lab. Another use is to make sure my wife’s oven is calibrated right, and maybe measure the occasional blowtorch temperature.

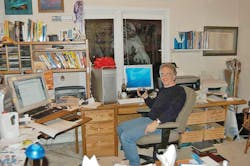

Are there any big life lessons you can pass along to young engineers or to folks in general?

To be really good at this job, you have to be a little obsessed and think about design possibilities all the time. I think about circuits in the shower, while falling asleep, basically any time my mind is free to roam (Fig. 8). You get so entwined with circuit details when you are at work that you don’t embrace the big picture. I was laying on the beach in LA when I got my first epiphany, that it might be possible to build a single amplifier stage with infinite gain. I got so excited, I ran home, changed clothes, and drove to work. An hour later, I had a breadboard that showed it worked.

8. One benefit of occasionally working at home is you can have a glass of wine while designing ground-breaking analog integrated circuits, as is the case with Carl Nelson.

You also have to learn to embrace Murphy’s Law and stay one step ahead of it. That means telling Spice to look at all the nooks and crannies of a design to be sure everything is well-behaved. Most problems that show up on silicon can be reproduced in Spice. You just have to ask it. Better for your career if you find the problems before first silicon; not after. I spend a lot more time running simulations after the design is done than in the actual design process.

One place that Spice breaks down is thermal interactions on the chip. I have designed quite a few high-current regulators, so I tend to think of any current below 100 mA as being thermally benign. Yet one of my recent designs had a thermal runaway problem in a 20-mA bias loop because it was all jammed into a tiny space. Spice never saw it coming.

I am now developing a method to do thermal modeling in Spice that takes into account each transistor’s temperature. It’s rudimentary, but it works, and lets you see die temperature unfold in front of you as time proceeds. I plan to include it in a macromodel of the LTZ1000 heated voltage reference, so customers can do thermal modeling as well as electrical. The Spice folks are choking on their lunch when they see this, but I think it’s the wave of the future.

I read that experience is a mean teacher. It gives the test before it gives the lesson. How important is experience in analog design, and your life in general?

Experience is very important. Young designers have a big leg up on us geezers because they don’t know what can’t be done. Yet they miss stuff, and that is where experience makes all the difference. Countless times designers working for me have come into my office all excited about some part of a project. Experience rears its ugly head and I tell them it’s either too good to be true, or it runs afoul of the Law of Unintended Consequences. I’ve always thought it was a damn shame most engineers have to learn subtle stuff the hard way, by making mistakes that cost time and money. There really needs to be a Bible of Analog Mistakes, so designers can finally stop repeating them.

Shout-Outs from Carl Nelson

I would like to acknowledge the people who helped make my career. One, of course, is Bob Dobkin, my boss for nearly 30 years. He made it fun to go to work every day, was a great friend outside of work, and his towering intellect certainly made me a better designer. Another was John Readdie, the fab manager at LTC. He put up with my meddling for many years, and promoted a climate of cooperation between fab and design that undoubtedly contributed to LTC’s success. Plus, he was very, very good at what he did.

Una Brown in Mask Design put up with my constant tweaks to layouts, often grumbling with her quick sarcastic wit, but always getting the job done right. We worked together for pretty much my whole career. Don Swanner, LTC lab manager, was (and still is) one of those invaluable guys who makes things happen seemingly by magic. I had to practice deliberately not asking him about some things, because I knew he would drop whatever he was doing and handle my problem, even if it messed with other responsibilities. His encyclopedic knowledge of what equipment and parts were around, where they were, or how to get them never ceased to amaze me. Plus he rode a motorcycle, as I did for several years, except he was good at it :-)

I always felt honored to work alongside Jim Williams, both at National Semiconductor and LTC. He was one of those people who understood things no matter how far you drilled down into them. His status as a world-class electronics guru never messed with his ego, and he was a great friend outside of work. Who else has the original computer from a Minuteman missile spread out on a wall hanging, with the opposite side of the wall displaying incredibly beautiful scientific instruments several centuries old?

About the Author

Paul Rako

Creative Director

Paul Rako is a creative director for Rako Studios. After attending GMI (now Kettering University) and the University of Michigan, he worked as an auto engineer in Detroit. He moved to Silicon Valley to start an engineering consulting company. After his share of startups and contract work, he became an apps engineer at National Semiconductor and a marketing maven at Analog Devices and Atmel. He also had a five-year stint at EDN magazine on the analog beat. His interests include politics, philosophy, motorcycles, and making music and videos. He has six Harley Sportsters, a studio full of musical instruments, a complete laboratory, and a video set at Tranquility Base, his home office in Sun City Center Florida.