This file type includes high resolution graphics and schematics.

In the beginning, clocking digital electronics was simple. You started with a basic Pierce oscillator, controlled by a piezoelectric quartz crystal, clipped the tops off the resulting sine waves, filtered out the noise, and divided-down the pulses to a usable clock rate. There was even programmability of a sort. Makers of semiconductor clock devices offered resistor-selectable divide-down rates. Later, some “silicon oscillators” used R-C multivibrators in lieu of quartz. They were less expensive, but offered less temperature stability.

That was the situation in the late 20th century and the early 21st. In 2006, SpectraLinear began offering greater programmability. The company’s EPro clock family incorporated up to four programmable phase-locked loops (PLLs) that allowed users to fine-tune output impedance (which in effect controlled drive strength), output skew, operating frequency, and spread-spectrum profile. Also, clock outputs often could be programmed to be in-phase or be 180° out of phase (see “Bulletproof Your System Timing With Programmable Clocks”).

When Silicon Labs acquired SpectraLinear, it gained additional expertise in clock programmability. That capability has more recently grown with a new CMOS-MEMS technology developed inside Silicon Labs. This technology is a late addition, however. SiTime, an independent startup, offered the first devices based on silicon microelectromechanical-systems (MEMS) clock resonators in 2006. In 2007, Discera announced products based on its PureSilicon MEMS technology. The company has not discussed PureSilicon’s details in the media, though.

Complementing its acquisition of SpectraLinear last June, Silicon Labs introduced what it characterized as the industry’s first single-die MEMS oscillator, meaning that its MEMS structures are built directly on top of the same CMOS wafers that incorporate its analog circuitry. (SiTime uses separate die.) Silicon Labs designates the products “CMEMS oscillators” and says the process supports wafer probing of complete oscillator systems for quality and process control (see “Inside Silicon Labs’ CMEMS Resonators”). More concretely, Silicon Labs guarantees that the products will meet their data-sheet performance specs for frequency stability relative to solder shift, load pulling, VDD variation, operating temperature range, vibration, and shock for at least 10 years.

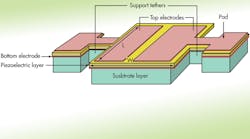

Similarly in 2010, IDT acquired Mobius, a startup founded by Michael McCorquodale that made silicon LC-resonator oscillators. But the following year, McCorquodale left and IDT announced pMEMs (piezo-MEMS) devices, pMEMs being an internally developed technology that uses quartz MEMS (Fig 1). Subsequently, in 2012 and 2013, IDT introduced advanced pMEMS products with multiple outputs and reduced jitter (see “pMEMS Oscillators Make Waves Without The Crystal”).

MEMS Vs. Piezoelectric Quartz

SiTime might be considered the grandfather of the business. Since shipping its first products in 2006, it has moved 160 million units to more than 800 customers, with 40 to 50 programmable devices yielding about 200,000 part numbers. It also commands 80% of the MEMS timing market. The company was founded on the expectation that resonators based on silicon MEMS technology, unlike piezoelectric quartz crustal resonators, could utilize the economies of the silicon foundry infrastructure to make inroads into quartz dominance.

Before the dawn of MEMS-based timing devices, piezoelectric quartz-based suppliers included IDT, Texas Instruments, Analog Devices, Silicon Labs, and Microsemi making analog semiconductor-based chips. Epson, Kyocera, NDK, and Vectron had the quartz crystal technology. Quartz-based suppliers could buy analog ICs from the semiconductor companies and the semiconductor suppliers could offer timing devices, using an external quartz device as a reference. There was no successful unified solution until SiTime integrated MEMS regulators with its own electronics.

“The quartz guys had a lock on their expertise in precision machining of quartz crystals. They could take a quartz crystal and cut it and do all kinds of things to it to make sure that it operated at a standard frequency and stayed that way for 15 or 20 years. And they made a fabulous job of it,” says Piyush Sevalia, executive vice president of marketing at SiTime.

Meanwhile, the semiconductor-clock companies didn’t have the expertise in the special kind of packaging that quartz crystals require. Quartz needs vacuum-sealed ceramic packaging to ensure that that the resonator’s Q remains high. The need for separate packaging of resonator and analog electronics had several drawbacks, not least that in consumer products, a lot of board space was taken up with clocks, limiting opportunities for miniaturization. In those days, a device put out one clock output, and designers had to accommodate that.

This file type includes high resolution graphics and schematics.

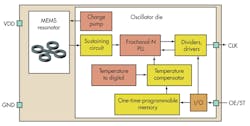

SiTime was the first to successfully resolve the various problems, probably because its founders’ backgrounds embraced both analog and silicon MEMS resonator expertise. Building the resonator out of silicon and packaging it with the clock’s analog circuitry made it possible to provide multiple clock outputs from a single, compact semiconductor package, providing product designers with greater versatility in their own packaging (Fig. 2).

For example, one of SiTimes’ MEMS wafers may look like any other semiconductor wafer. Yet it can hold from 30,000 to 50,000 or more MEMS die that are vacuum-sealed as part of the wafer processing. For an animation of the entire process, see www.sitime.com/videos/mems-first.html.

MEMS Markets

Today, these products have become essential for the latest digital cameras, tablets, camcorders, e-readers, set-top boxes, and consumer entertainment equipment. On the communications side, they go into switches, routers, basestations, solid-state drives, and cloud storage.

The ability to use a conventional 0.18-µm silicon-foundry process and back-end technology was of some advantage, but it still left quartz a competitive edge when price was a buyer’s only criterion. However, silicon made inroads because of its supply chain advantages, reliability, and robustness.

“Because it’s silicon, we can get fully configured devices shipped in production in three to four weeks. With quartz, it might take eight to 10 weeks to get that. We can also be 10 times more reliable and 10 or 20 times more robust in terms of resistance to shock and vibration,” Sevalia says.

Sevalia says market penetration also has accelerated as products for end users get smaller.

“Smart phones typically did not use MEMS timing components until we came out with a tiny 32-kHz device,” he says. “This could be a breakthrough, the proverbial hockey stick, that can drive revenues for the MEMS-timing companies dramatically. The industry, as a whole, could benefit.”

For instance, wearable electronics such as the personal health monitors use SiTime’s 32-kHz devices. Additionally, another set of new applications for silicon clocks is keeping networking systems synchronized.

“Your cell phone tells time. It’s got a local clock for that. But that local clock must be synchronized to a global central clock. In femtocells, they’re talking about synchronizing to GPS, among other options. The way to do that would be to have a local clock plus some algorithms and software to do the synchronizing function,” Sevalia says.

“In general, we think the synchronization trend is going to go towards greater precision, which implies that frequency stability must similarly get better and better. If a clock’s frequency is not precise, the window of uncertainty expands and you can’t get the level of performance required,” he says.

Particularly in mobile, the emphasis on precision is a recent trend.

“Jitter performance will have to get better over time,” he says, “because jitter reduces the window of uncertainty during which a clock and data can be synchronized.”

Adding Features

Exclusive of MEMS resonators, programmability has been an important part of all of these companies’ positioning. Silicon Labs and SiTime each have a programmer that allows them to program these devices and have samples within a matter of seconds. For its communications customers, SiTime has additionally focused on high-temperature (125°C) operation. Most communications equipment runs in outdoor environments, so it needs to be able to withstand the 40°C to 45°C temperatures that are common in hot places. They can offer oscillators with guaranteed operation up to 125°C.

Each device provides temperature compensation to cancel out the frequency drift as temperature changes affect the resonator. Then, you have the output drivers and one-time programmable memory. SiTime has been able to design kilohertz devices with jitter as low as 500 fs, stability as low as 0.1 ppm, and very low (700 nA) power consumption.

Programmable parameters include drive strength; rise and fall times to reduce electromagnetic interference (EMI), improve jitter, or drive large/small loads; frequency to six decimals of accuracy; and stability, temperature, and signaling level (LVPECL or LVDS). For long traces, designers can make the drive stronger. If the trace is short, they can make the drive strength weaker and reduce EMI.

For a standard 15-pf load, standard drive strengths will result in a typical square wave. If designers wanted to drive a softer load, they would get pulses with fast leading edges. If they want to drive a harder load, they would get a softer leading edge. There is a significant difference in EMI between the two. So if designers are looking to their clock source to reduce EMI, a soft edge can help.

Latest SiTime Products

SiTime’s recent 32-kHz SiT15xx family of can be further divided into SiT153x devices that operate from a 1.2- to 3.63-V regulated supply, and SiT154x devices that operate from an unregulated 2.7- to 4.5V power source. Both come in comes in chip-scale packaging. The former are aimed at smartphones that use coin-cell or super-cap battery backup; the latter are for devices that use Li-Ion batteries.

Announced in March, they are presently the smallest timing devices for 32-kHz timekeeping functions, with a total footprint fully 85% smaller than the closest competing devices. None of the devices in the family require external decoupling, or load capacitors. (Quartz resonators typically require a load capacitor for excitation.) The small footprint makes the devices attractive for smart phones and tablets (see “Inside SiTimes’ Resonators,”).

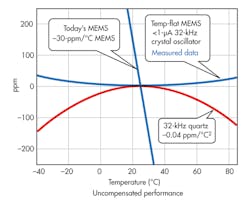

Originally, SiTime MEMS resonators exhibited a frequency-stability variation of 30 ppm/°C. Over a temperature range from –40°C to 85°C, there could be as much as a 4000-ppm variation before temperature compensation in the analog electronics bought the clock output variation down to as low as 0.1 ppm. In comparison, kHz quartz devices natively achieve 0.4-ppm stability.

In July, the company introduced TempFlat MEMS, intended for smart phones. These differ from previous MEMS oscillators that used compensation circuitry to stabilize the output frequency over temperature. They are the first MEMS resonators that are natively able to outperform quartz resonators without temperature compensation. The advantage is, if it isn’t necessary compensate a resonator variation of 30 ppm/°C, for example, the circuit consumes less power, the die area is smaller, the circuit performs better, and the system design is easier. (fig 3)

This file type includes high resolution graphics and schematics.