The rotating-mass gyroscope, which lies at the heart of inertial measurement units (IMUs), has served very successfully from the 1930s to the 1970s, guiding astronauts, spacecraft, missiles, and more. It was superseded in 1970s by the ring laser gyro (RLG) and then the fiber optic gyro (FOG), both “strap down” units with no moving parts, no need for complex gimbals, and no risk of “gimbal lock.” The next evolutionary step comprises MEMS-based gyros and accelerometers—tiny, inexpensive, and low power—which are now widely used in consumer, commercial, and many critical military applications.

However, these MEMS gyros can’t yet match the performance of the best RLGs and FOGs. The latter exploit the shifting of the interference fringes that are generated between opposing optical wavefronts, analogous to changes in musical beat notes. As the optical-gyro assembly rotates, the frequencies of each optical wave changes (known as the Sagnac effect). Thus, the fringes shift as well, with the measured shift a precise indication of the magnitude of the rotational motion.

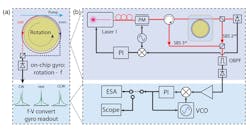

1. The MEMS resonator is the core of the laser gyro , but many additional electronic and optical components are also needed (PM = phase modulator; SBS = stimulated Brillouin scattering; PI = proportional-integral servo loop; OBPF = optical bandpass filter; VCO = voltage controlled oscillator; ESA = electronic spectrum analyzer). (Source: Journal of the Optical Society of America)

Hoping to overcome the relatively weaker performance of MEMS-based devices, yet retain their benefits, a team at the California Institute of Technology (Caltech) is building a gyro that exploits multiple advanced electro-optical effects within a sophisticated MEMS structure (see “Microresonator Brillouin gyroscope”). Their design uses a pair of solid-state Brillouin laser wavefronts launched on counter-rotatating paths, as is the case with other optical gyros (a Brillouin wave is the result of nonlinear interaction between an optical wave and a solid material). Rather than use mirrors (as in the RLG) or optical fiber (as in the FOG), their device uses an 18-mm-diameter silica disk functioning as a precisely tuned high-Q microresonator, and it excites this resonant chamber via pumping of a single laser.

Technology Merge

While the MEMS resonator is the heart of the system, it takes a complex array of electronic, optical, and electro-optical functions to complete the system (Fig. 1), and operation involves much more than just generating that laser wavefront.

The initial Brillouin laser-pumping action induces a Stokes wave, a nonlinear periodic wave propagating along a nearly frictionless surface (analogous to an ocean wave that travels for extreme distances under the right conditions). Here, the Stokes wave pump initiates a second Brillouin wave that propagates in the opposite direction, which in turn induces yet another Stokes wave, and so on, as a Brillouin laser cascade. The overall effect thus mimics the action of the much-larger RLG/FOG, but entirely within the MEMS device.

The Caltech researchers evaluated their microresonator Brillouin gyroscope by packaging it in a small box (Fig. 2). One corner is hinged while the other was moved with an angular amplitude of 0.14 degrees at a rate of 7.5 Hz using a piezoelectric actuator.

2. The gyro prototype is housed in a box with optical-fiber input and output connectors; the 18-mm-diameter MEMS resonator is the gray device in the center. (Source: Journal of the Optical Society of America)

They reported sensitivity of 15 deg/hr/Hz2, Sagnac detection bandwidth of more than 1 kHz, and sensed a minimum rms rotation rate of 6.3 x 10-3 deg/sec (22 deg/hr), which they say is about 40 times better than previous attempts at micro-optical laser gyroscopes. They hope to improve performance by narrowing the bandwidth of the laser output.

If this project reaches practical maturity, it could takes MEMS-based guidance to another level of performance. In fact, it could very well rival the RLG, FOG, and even top-tier mechanical devices, but in a smaller, lower-power package.