Capacitors, resistors, inductors, connectors, and even the printed-circuit board (PCB) are called passive because they don’t have gain or control power like semiconductors or other active devices (see “Passive Components Aren’t Really So Passive (Part 1): Capacitors”). But these apparently passive components can, and do, change the signal in unexpected ways because they all have parasitic portions. So while resistors may seem to be simple, benign, passive devices, they really do some unexpected things.

The Not So Simple Resistor

How many times have we walked down a street and seen concrete that is lumpy, bumpy, and horrible? It reveals someone’s inexperience and overconfidence because pouring concrete looked so simple. Resistors similarly seem simple until one looks closely. The late Felix Zandman and the other authors of the superb Resistor Theory and Technology have the same lament.1 “This work attempts to demonstrate that the design and fabrication of resistive components require the application of particularly complex physical phenomena and are no longer based on the traditional empirical methods generally associated with the ‘kitchen recipe’ approach,” they write.2

Related Articles

- What's The Difference Between Foil And Thin-Film Resistors?

- Understanding Power Resistors And Their Impact On Thermal Management Decisions

- The Right Resistors Enable LED Lighting

Ahhh, the kitchen. While cooking, so many of our mothers used to use “a little of this and a pinch of that.” That’s fine for cookies, but this kitchen-recipe approach to manufacturing resistors is a serious issue. Some vendors prioritize price over quality. Others accept a large variation in tolerances as if they were formulating batches using a kitchen recipe. A little difference in food can add variety and interest, but the kitchen recipe has no place in manufacturing close tolerance parts.

Zandman, inventor of a zero-tempco resistor and founder of Vishay Intertechnology, certainly underscored his work with mathematics and material science. His book delineates the formulas and reasons behind the many variations in resistors. He devotes three wonderful chapters to Ohm’s law, first to Ohm’s law itself and its limitations, then to reversible and irreversible phenomena associated with the law. Reversible conditions include a rise in temperature that changes the resistance, but the resistance returns to the starting point when the temperature is reduced. An irreversible effect means that the resistor’s change becomes permanent like those caused by diffusion or oxidation.

This file type includes high resolution graphics and schematics when applicable.

Set Tolerances To Match The Application

Let’s admit an important fact at the outset: resistors introduce error. Our initial reaction may be to ignore resistor inaccuracy as too small to matter. After all, a pinch of salt in an Olympic-sized swimming pool does not make it salt water, but adding a ton of salt would be a different issue. Obviously, an application dictates the acceptable error. The more precision required, the tighter the component tolerances must be. Knowing this, we should define what magnitude of error is acceptable.

We will examine an example system with 12-bit resolution. One-half the least significant bit (LSB) is one part in 8192, or 0.012%, or 122 parts per million (ppm).3 A quick look at Digi-Key and Mouser catalogs finds thousands of 1% tolerance resistors with typically a ±100-ppm/°C temperature coefficient (tempco). Consequently, barely more than a 1°C temperature change will cause more than one LSB deviation. That’s not so good. So let’s try 0.1% tolerance resistors with ±25 ppm/°C, which means if the temperature changes 5°C, our error is one LSB. Remember that this is just one resistor and most systems have many resistors.

We can draw some important conclusions from this example. To bracket the resolution numbers:

• For 8-bit (1 part in 256) resolution, one-half LSB is 0.195% or 1953 ppm.

• At 16-bit resolution (1 part in 65536), one-half LSB is 0.0015% or 15 ppm.

Clearly the need for smaller tolerances and tempco is more important at higher resolutions.

That is actually true for many systems, but there are two extreme cases to note. First, a completely open-loop use, such as an arbitrary waveform generator, will need the digital-to-analog converter (DAC) output and amplifier to have nearly perfect linearity. Second, a system with a feedback loop, such as a mechanical movement generated in a process controller, has servo action that will always be driving the action toward the center to null out any error. As long as the servo is directed in the proper direction (the system is, by definition, monotonic), small nonlinearity errors will be ignored.

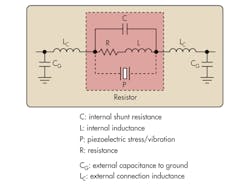

Resistor Parasitic Components

Resistors have parasitic components. The resistor is inside the dotted resistor box in the figure. The inductors and capacitors on either side are the PCB connections and traces. The R is what we want. The additional factors inside that box are unavoidable parasitics. To illustrate the effects of these parasitics, we drive the left side of the resistor with a low-impedance signal generator. That will swap out the left capacitor to ground, CG.

To the right of the resistor we see the composite of all the network components. A frequency sweep of a sine wave will show the dominant RC high-frequency rolloff caused by resistor R and the right-side capacitor CG. The series inductors will cause additional but minor high-frequency attenuation. The capacitor C and inductor L inside the resistor will cause a minor frequency peaking. Yes, each of the parasitic components is small. Still, we need to consider them when designing circuits so we can decide whether or not to ignore them. For example, at audio frequencies we can choose to disregard the parasitics, but at radio frequencies we may have to adjust for them.

The piezoelectric element, P, is interesting as it influences performance during stress and vibration. It also could represent a magnetostriction response to a magnetic field. Stress can change the resistance depending on the resistor chemistry, and vibration can be converted into small ac voltages that then add to the electrical noise. The solder stress is probably dominant and is important, especially with surface-mount parts. Older designs with through-hole resistors allowed the leads to twist to absorb and mitigate most of the stress. Surface-mount parts, however, are held against a relatively rigid PCB. As the solder solidifies, these parts capture the change in thermal expansion between the resistor and PCB. To minimize the stress we must carefully follow the manufacturer’s recommendations for solder time/temperature profile.

Wire-wound resistors often are chosen because they have very low temperature coefficients (tempcos). These resistors also have an important, unique characteristic—their structure can react to magnetic fields. Because they are essentially coils of wire, they magnify a magnetic field, which a single conductor might pick up. As a coil, they also have more inductance than other types of resistors. We have seen circuits with transformers, inductors, and wire-wound resistors cross talk via small magnet fields. To mitigate these effects, careful layout, rotating components 90°, increasing the spacing, and shielding may be necessary.

Finally, don’t forget our friend Seebeck. Any dissimilar metal connections such as those at the solder-to-board interface can cause small temperature-dependant offset voltages.

Manufacturing Tolerance, Power Rating, And Tempco

Two other parameters, manufacturing tolerance and power rating (wattage), also impact resistor operation. Sorting and binning can distort manufacturing tolerances. This can also happen with some kinds of resistors.4 As a general rule, binning can cause performance problems for both manufacturers and customers if there is a process shift and then there is a large demand for the most precise item.

A manufacturer can always ship parts that are more precise in place of low-precision parts, but the reverse is not true. For example, a 5% tolerance resistor could include resistors with a tolerance between –5% to –2% and +2% to +5%. This is clearly not the full range between –5% through +5% that one might expect. If not enough high-precision devices are binned or if the customers only want the high-precision parts, then the manufacturer faces parts shortages.

Power rating is simple, right? Voltage times the current (V × I) tells you what wattage rating to choose so the resistor does not burn up from self-heating. Right? Wrong—or maybe? The answer, of course, depends on the application. A series resistor to limit current in an LED can be a plain “vanilla” circuit where little additional concern is necessary. If the resistor has a negative tempco, the resistance is reduced as the temperature increases. This, in turn, causes the resistor to draw more current at higher temperature, and that can contribute to overheating. At the other extreme, bias and modulation currents are critical in radio and laser communications systems.

Many systems including radio and laser communications systems need to remain stable over the operational temperature extremes. Centering the feedback loop over temperature and voltage changes requires deeper study. How much power is dissipated and how each of the components reacts, including the resistor, is important. In such circuits the laser must be cooled to keep it on frequency. The heat of the surrounding components (self-heating) must also be removed. What do you do? There are questions to ask and answer before your design goes any further:

• Is there airflow across the circuit?

• What is the temperature of the air at the critical circuit (not just the air entering the enclosure)?

• Was the air heated by another circuit?

• Many times the air is first routed to the circuit boards and then exits through the power supply. Does the power-supply voltage change with temperature now?

• Are other systems racked together in the same enclosure?

• Are there fans? How does dust and dirt collect, and what happens if one or more fans fail?

Most resistors have a negative tempco, meaning the resistance is reduced at higher temperatures. This also means that the resistor will draw more power when heated. Each of us needs to carefully read a resistor’s data sheet because the different chemistries and manufacturers may have different ways of specifying the tempco. The tempco curves can be just about any shape and may be specified by the “box method,” which is common for ICs.5

Even a factory-trimmed part with thousands of transistors will show a family of curves over temperature and process variation. Simulation and correlation allow us to define a box that contains all the possible curves. The box “x axis” is the total operating temperature. The “y axis” is the total magnitude of the error. Statistically we guarantee that the error of all the parts is within the box, but we do not know the shape of the curve for any individual part.6 Specialized resistors called thermistors can have negative (NTC) or positive (PTC) tempcos, and the curves tend to be very nonlinear.

Basic Chemistry And VCR

The chemistry inside IC resistors is very important for understanding resistance. Designers and process engineers need to understand how chemistry in the manufacturing process affects resistor performance.7

In chemistry there are two broad classifications for things made of one or more chemicals. A compound comprises two or more chemicals that react to make something new. A mixture comprises multiple mixed chemicals that retain their original properties. Remember that the resistors with color bands on a brown shell are carbon composition (CC) resistors. The CC resistors are mixtures, and some of the contact points inside form semiconductors. They change resistance with heating, cooling, vibration, and applied voltage.

The high-voltage vacuum tubes (“valves” in the U.K.) of our past (and that still “resonate” for some audiophiles today) created “resistor distortion” that some people find pleasant.8 The distortion is caused by a voltage coefficient of resistance (VCR), a reduction in resistance value with an increase in voltage.

In an audio system with a sine-wave signal of 75 V p-p, biased at 50 V, the resistor that sets gain will be at a higher resistance (gain) on the lower half of the sine wave and have a lower resistance and gain on the positive peak. This adds second-harmonic errors to the signal. This “resistor distortion” is soft and smooth in the onset of distortion, which, as mentioned above, some find pleasant. For most resistors the voltage-coefficient error only becomes measurable over 25 V. Most circuits are lower voltage today, so the resistor distortion tends to be ignored.

VCR is an important characteristic of high-voltage thick-film resistors.9 Typical thick-film ink consists of conductive material suspended in an insulating matrix. As the voltage across the ink is increased, new conducting paths are opened. The result is a drop in resistance. This means that the VCR is always negative in value.

Thick-film resistors can be used as series-protection resistors in electrocardiogram (ECG) input circuits. These resistors help protect the ECG input from the 3 kV to 5 kV from defibrillator pulses.10 Obviously, we want the resistors to maintain their value and survive multiple voltage pulses. There are resistors with a VCR of less than –1 ppm to 5 ppm over a large working voltage. With ECG, the humidity and the temperature performance of the resistor are critical. The resistor also must dissipate the heat energy of the defibrillator pulses.

Thus, while the IC designer does not define the internal chemistry of a circuitry, it is important to understand how chemistry affects the tolerance and tempco of the part. Once again, this speaks to the importance of studying the data sheet.

Thermal, White, Or Johnson Noise

Thermal noise, also called Johnson noise, is present in all passive resistive elements. The random thermal motion of electrons causes it. The thermal noise level is unaffected by dc current.

Resistors always generate noise, even when floating outside a closed circuit. This is white noise, which has a uniform spectral density and increases with temperature and resistance. Because some resistors are made of semiconductors, they can have other types of noise such as shot, avalanche, flicker (1/f), and popcorn noise. A free thermal noise calculator and a user’s guide further explain the different noise types.11

Conclusion

Good engineering is about the details, and we are fortunate to be standing on the shoulders of engineering giants. Pioneering engineers like Zandman have struggled while researching physics and materials science, executing the careful work that produced the understanding that we rely on every day. As he observed, the seemingly small insignificant factors in an IC are many times taken for granted.

This is certainly true for resistors that seem to be benign and passive, until their performance in a circuit startles us awake. That little resistor, in fact, dominates the circuit’s error budget. Tempco and manufacturing tolerance are just the start. That passive resistor can change value with voltage and actually lowpass filter a signal. The effect is unexpected and surprising until we look closely and realize that there is more to a resistor. Ultimately, the resistor that we tried to ignore is just following the laws of physics, and we need to pay it special attention.

References

1. Zandman, Felix, et al., Resistor Theory and Technology, Vishay Intertechnology Inc., 2001.

2. Ibid., Introduction, p. 3.

3. Maxim Integrated tutorial 5060, “ADC/DAC Accuracy Calculator Tutorial,” http://www.maximintegrated.com/AN5060; For a free “Accuracy Calculator” (ACCU), see http://www.maximintegrated.com/design/tools/calculators/hp50g/.

4. Laumeister, Bill, “Passive Components Aren’t Really So Passive (Part 1): Capacitors,” Electronic Design, June 4, 2013, http://electronicdesign.com/power/passive-components-aren-t-really-so-passive-part-1-capacitors.

5. Maxim Integrated application note 4419, “Understanding Voltage-Reference Temperature Drift,” http://www.maximintegrated.com/AN4419.

6. Maxim Integrated tutorial 5062, “Bandgap Reference Calculator Tutorial,” http://www.maximintegrated.com/AN5062; the free calculator includes the User’s Guide in the calculator documentation zip file, which explains the theory and practical operation in detail.

7. Thei, K.B., et al., Characteristics of Polysilicon Resistors for Sub-Quarter Micron CMOS Applications, Institute Of Microelectronics, Department of Electrical Engineering, National Cheng-Kung University, Taiwan, http://www.essderc2002.deis.unibo.it/data/pdf/KB.pdf.

8. Keen, R.G., Using the Carbon Comp Resistor for Magic Mojo, 2002, http://www.geofex.com/article_folders/carbon_comp/carboncomp.htm.

9. Birkett, M., “VCR Characteristics of High Voltage Thick Film Resistors,” Resistor Business Unit, TT electronics Welwyn, July 2007, http://www.digikey.com/Web%20Export/Supplier%20Content/tt-electronics-welwyn-985/pdf/tt-electronics-vcr-characteristics-high-voltage.pdf?redirected=1.

10. Oxley, Stephen, “High reliability passive components in three broad areas: Contact, imaging, analysis,” TT electronics, Fixed Resistors Business Unit, 7 April 2011, http://www.digikey.com/Web%20Export/Supplier%20Content/tt-electronics-welwyn-985/pdf/welwyn-doi-resistors-for-medical-sector.pdf?redirected=1

11. Maxim Integrated tutorial 5059, “Thermal Noise Calculator Tutorial,” http://www.maximintegrated.com/AN5059

Bill Laumeister is an engineer in strategic applications with the Precision Control Group at Maxim Integrated. He works with customers who use DACs, digital potentiometers, and voltage references. He has more than 30 years of experience and holds several patents.

This file type includes high resolution graphics and schematics when applicapable.