Use Analog Foundries To Optimize The Photonic Elements In Your SoC ICs

Today’s analog foundries can integrate sensors with highly optimized analog and digital functions on a single chip. It’s possible to sense physical phenomena such as pressure, temperature, magnetic field, and light, digitize them, and apply signal processing, all in one system-on-a-chip, or SoC (Fig. 1).

This is a prime differentiator between conventional foundries and analog foundries. Conventional foundries provide state-of-the-art CMOS feature sizes, but they can only integrate and support a limited range of analog functional blocks.

For analog foundries that integrate light sensors in SoCs, the requirements for integrating optical sensors can vary for light sensitivity, supported wave length, bandwidth, and noise. Depending on the application, one or more of these factors could be important. Analog foundries can optimize their processes to match the requirements for one or more of these factors.

There are three light-sensitive devices in a CMOS process: photo diodes, photo transistors, and photo resistors. Photo diodes are commonly used as optical sensors. Silicon is light-sensitive, so every diode can be used as a photo diode to convert light into current. If light reaches the base collector junction of a bipolar transistor through a transparent case, a photo transistor can be created.

Photo transistors can be up to 100 times more sensitive than photo diodes, but they are slower in response time. For photo resistors, resistance is changed by light. Photo resistors often are used as discrete devices. Integration in a CMOS process isn’t common. Most applications use photo diodes in SoCs.

PHOTO DIODES AS OPTICAL SENSORS

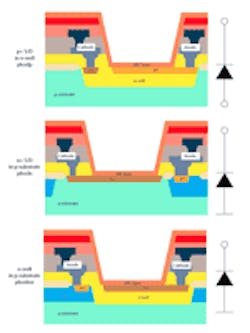

Analog foundries can offer various diodes with different kinds of pn junctions (Fig. 2), doping profiles, and junction thicknesses, yielding different behaviors. Due to the modularity of foundry processes, several diffusions and well implants are available.

In X-Fab’s 0.6-µm CMOS process, the n-diffusion/p-substrate (phodn) and n-well/p-substrate (phodnw) configurations have a sensitivity peak at 700 nm. Maximum sensitivity is 0.35 mA/mW. The photo diode p-diffusion/n-well (phodp) has its highest sensitivity at 450 nm. Its overall sensitivity is lower than that of the p-substrate diodes.

PHOTO DIODE APPLICATIONS

Photo diodes are used in a wide range of applications. The availability of different doping profiles gives analog foundry users a wide selection of photo diodes for use in applications such as ambient light sensors. These sensors with standard diodes require high sensitivity for visible light. Silicon photo diodes are sensitive for visible and IR. However, the IR portion of the light should be suppressed.

An ambient light sensor (ALS) (Fig. 3) with human eye behavior is possible through a combination of two diodes. Diode dlw is sensitive for the spectrum from ultraviolet (UV) to infrared (IR) light. Diode dwplw is especially sensitive for IR light. By calculation, the IR part can be subtracted from the dlw sensitivity curve, resulting in a sensitive curve that very closely approximates the sensitivity of the human eye.

In contrast, a Blu-ray PIN diode must detect weak signals reflected from a disk surface. It requires high sensitivity and a high signal-to-noise ratio to do this because of the direct correlation between speed and bandwidth. The Blu-ray PIN diode needs high bandwidth to accommodate the current 8x speed requirement, which is expected to reach 12x in the near future.

Foundries must support Blu-ray using laser diodes with 405-nm legacy DVDs at 650 nm and CDs at 780 nm. This support requires PIN diodes (Fig. 4) optimized for 405 nm with acceptable sensitivity for red/IR light. By positioning a cathode implant below the ARC layer, it’s possible to achieve high sensitivity to blue light.

Due to the level of sensitivity, careful engineering is necessary to interface the anti-reflective coating to silicon. Red and IR light is detected deeper in the material. High-ohmic EPI wafer material is used to support high bandwidth at 405, 650, and 780 nm.

OPTICAL WINDOW ETCHING

Although diodes can be used as photo diodes just as they are, they aren’t optimized for sensitivity. Using them this way has two primary disadvantages. First, the material on top of the photo diode reduces transmission (Fig. 5). Second, the allowed tolerances of the isolator stack above the diode can cause unpredictable losses for dedicated wavelengths, due to interference at the dielectric layer interfaces. Solutions exist for both problems, though.

The reduced transmission problem can be dealt with by etching away the material on top, giving light photons direct access to the diode surface. Applying an anti-reflective coating (ARC) protects the diode surface and reduces interference losses. Some specialized analog foundries offer window etching and ARC layer application as an additional optional technology module.

PHOTO DIODE ADJUSTMENT

Analog foundries can adjust their processes to meet the requirements of different applications. Thus, depending on customer needs, ARC layer thickness (Fig. 6) can be adjusted to support defined wavelengths. PIN diode dpin is optimized for photo detector ICs (PDICs) for DVD/CD drives that require optimum sensitivity for 650 nm (DVDs) and 780 nm (CDs), respectively. In contrast, PIN diode dpinb also supports Blu-ray, as it was optimized for 405 nm. Sensitivity for 405 nm was increased, while sensitivity between 600 and 800 nm was slightly reduced.

The selection of wafer materials significantly impacts the bandwidth. For example, high-ohmic/low-doped wafer material permits the creation of low-capacitance PIN diodes supporting high speed over a broad wavelength. Doping also influences bandwidth. Deep pn-junctions are best for high-speed red/IR diodes. High-bandwidth photo diodes for short wavelengths such as blue light need thinner pn-junctions.

As a result, an analog foundry can vary sensitivity, bandwidth, and noise by window etching; by varying the thickness of the ARC level; and by the selection of various wafer materials and doping profiles to meet customer application requirements.

PHOTO DIODES AS CHARACTERIZED PRIMITIVE DEVICES

Analog foundry customers can use every diode, with and without optical windows, as photo diodes. Diode design and characterization are typically the customer’s responsibility. But as a special service, some analog foundries offer photo diodes as characterized devices for frequently used applications. These characterized photo diodes are included in the design kit. Therefore, they are easy to integrate. Simulation models covering various different operating conditions are also available for these characterized photo diodes.

Using this approach, the risk of layout failures is reduced as the photo diodes can be extracted from the layout for layout versus schematic (LVS) verification. During production, process control monitoring (PCM) checks the quality of the characterized photo diodes. The foundry creates special structures in the scribe line that are checked during the wafer process to guarantee the functionality of the characterized photo diode.

FUTURE TECHNOLOGY INTEGRATION

Looking ahead two or three years, photonic crystals are expected to replace external filters. These optical nanostructures affect the motion of photons similarly to the way that semiconductor crystals affect the motion of electrons. Very small metal structures approximately the size of a light wavelength are used to create such filters within the normal IC process. As photonic crystals become part of the standard foundry flow, costs will be driven down.

Given the flexibility of analog foundries to optimize optical elements in SoC ICs in the ARC layer or by other means today, the possibilities for future technology integration seem limitless. By incorporating sensors in SoCs to interact with physical parameters, analog foundries are advancing the microelectronics evolution in exciting new directions, opening as-yet unheard-of application possibilities for biotechnology and other realms.