If you’re a moderately well-informed planet dweller you might know that a mid-sized 30-mpg car driving 12,000 miles/year creates about 3.55 tons of CO2. But even if you can’t quite cite the greenhouse gas amounts, you probably will acknowledge that electricity is generally a cleaner energy source than gasoline. Why then aren’t more of us driving electric vehicles (EVs)? The reasons are few but strong: EVs have limited range (and come with an accompanying fear of being stranded), diminished driving performance due to increased vehicle weight, and a lengthy battery-charging process.

In an attempt to overcome these shortcomings, automakers and their semiconductor industry compatriots are looking to wireless charging— energy sent through an inductive coupling to recharge EV batteries.

Wireless charging comes in two flavors: stationary or dynamic charging. In stationary charging, EVs charge wirelessly when they are parked using charging pads similar to the way you charge mobile devices today.

Dynamic electric vehicle charging (DEVC) refers to a technology that can both supply power and perform charging while the vehicle is driving, increasing the on-road time of EVs. Among the benefits of dynamic charging is that it allows smaller and lighter batteries to be used in EVs by employing a charging infrastructure embedded under roads.

Qualcomm recently reported that it has conducted a dynamic charging test on a test track in Versailles, France, using two Renault Kangoo vans driving over embedded pads in the road that transferred a charge to the cars’ batteries at up to 20 kilowatts and at highway speeds of up to 100km/hr.

The dynamic charging demonstrations, based on Qualcomm’s HALO technology, took place at the 100-meter FABRIC test track, comprised of 4 x 25 meter sections, each running from its own power supply, built in Satory, Versailles, to demonstrate DEVC capabilities. Power is transmitted across an air gap to two 10 kW vehicle pads located under the EVs.

Unfortunately the infrastructure needed to do dynamic charging could well prove to be prohibitively expensive and time-consuming to construct; studies have suggested that it would cost around 4 million euros (approx. $4.5 million) per kilometer of highway.

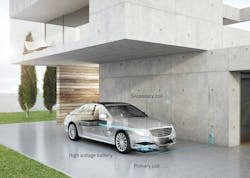

As such, Qualcomm is far from inactive on the less costly static charging front as well, again using its Halo technology. The company is working with DaimlerChrysler to install a next-generation static wireless charging system in the hybrid version of the 2018 Mercedes-Benz S550e. Drivers of cars equipped with the wireless charging option will simply park atop a special pad and charging will begin. Qualcomm Halo uses resonant magnetic induction to transfer energy wirelessly, from a ground-based pad to another pad integrated in the vehicle. Magnetic resonance has a longer power transmission range than electromagnetic induction, realized by equalizing the resonant frequency of the transmitting pad and the receiving pad.

The 2018 Mercedes Benz S550e will be offered with a wireless charging option.

Honda also wants to charge electric vehicles dynamically at high speed on highways. At the SAE World Congress in April a team from Honda R&D presented a paper entitled “Study of High Power Dynamic Charging Systems.”

The paper (SAE Technical Paper 2017-01-1245, 2017) reported on Honda research into developing a high-power, contact-type dynamic charging system for electric vehicles. Eschewing the wireless aspect would reduce the cost needed for vehicles to charge by receiving power directly from infrastructure while in motion, according to Honda.

That word recurs: cost. Supplying 450 kW of power would represent a ratio of vehicle cruising range to charging lane length of 25:1. Put another way, you would need charging lanes in 4% of the total distance traveled or approximately two kilometers of charging lane for every 50 km. of highway. The best part is Honda projects that using its approach would cost only 1/20th the cost of a similar wireless charging system.

According to Honda, the system that they developed and tested enables dynamic charging at a level of 180 kW (DC 600 V, 300 A) for cars and 400 kW for heavy duty vehicles driving at a vehicle speed (for cars) of 155 km/h (96 mph). Development is proceeding with a view toward supplying 450 kW of power (DC 750 V, 600 A) at a vehicle speed of 200 km/h during charging.

In another test, Toshiba has been using a wireless static rechargeable battery system to energize buses that provide regular service in Japan between All Nippon Airways Co. Ltd. facilities in Kawasaki and the vicinity of Haneda Airport in Tokyo. The tests were carried out with the cooperation of Waseda University, using a 44 kW wireless system feeding power to the battery when the bus is parked over charger pads. It employs a magnetic resonance system operating in the 85 kHz band. Toshiba said it selected magnetic resonance because it doesn’t require the transmitting and receiving pads to be as precisely aligned as systems that rely on electromagnetic induction. The charging pad in Toshiba’s system can be misaligned by as much 20 cm, and the two pads can be as far apart as 10 cm. according to the company.

As with everything involving electronic design, standards are integral to creating a successful easy-to-charge EV. In January, SAE members agreed on specifications for SAE J2954 Test Stations, which automakers will use to verify that their wireless charging systems will interoperate with systems and vehicles sold by other makers. The WPT1 (3.7 kW) circular coil system and the WPT2 (7.7 kW) circular coil system are included in the Test Stations. Agreement is expected to be reached later this year for wireless charging systems capable of WPT3 (11 kW) charge rates. The final SAE J2954 Standard is expected to be published in 2018.