Hyundai Previews Longer-Range 2018 Hydrogen Fuel-Cell SUV

Download this article in PDF format.

At a special preview event held in Seoul, Hyundai Motor offered an early glimpse of its next-generation fuel-cell vehicle, well ahead of the hydrogen-powered SUV’s official launch early next year. The new SUV (Fig. 1) is the company’s second commercially produced hydrogen model, and uses the company’s fourth generation of hydrogen fuel-cell technology.

1. To improve fuel efficiency, Hyundai’s FCEV features low-drag aerodynamic elements such as door handles that sit flush to the car. (Source: Hyundai Motor Company)

By way of review, a fuel cell is an electrochemical device that converts hydrogen to electricity (and heat) by means of interaction with a catalyst and oxygen. Water is the only by-product, making fuel cells environmentally friendly.

Senior VP Lee Ki-sang of Hyundai Motor Group’s Eco Technology Center characterized the second-generation FCEV as having “60% better system efficiency than the first-generation FCEV,” through internal development of fuel cells and powertrain components such as the electric motor.

According to Lee Ki-sang, by enhancing fuel-cell performance, reducing hydrogen consumption, and optimizing key mechanisms, Hyundai has greatly improved the vehicle’s efficiency compared to its predecessor, the ix35 Fuel Cell car (known in the U.S. as the Hyundai Tucson FCEV). The new efficiency level of 60% represents a 9% increase from the Tucson’s 55.3%.

The second-generation model targets a driving range of about 580 kilometers (360 miles) between fill-ups. The driving range of the current Hyundai Tucson Fuel Cell vehicle is up to 265 miles.

Unlike electric vehicles that can take several hours to fully recharge, one can refuel a fuel-cell car in two to three minutes. Providing the owner can find a hydrogen fueling station. While Toyota, Honda, and General Motors also are investing heavily in fuel-cell technology, hydrogen filling stations are very scarce. South Korea plans to increase the number of these stations from 16 this year to 100 stations by 2020, in order to sharply raise sales of fuel-cell vehicles. The country is aiming to have 10,000 fuel-cell vehicles on its roads by 2020.

The new model’s maximum output has been enhanced by 20% compared to its predecessor, and it boasts 163PS of power (PS is Pferdestärke, German for horsepower, equal to metric horsepower). Converted to imperial horsepower, it would be 160.8hp. The fuel-cell SUV is also said to improve the car’s cold-start capability, overcoming the challenges of starting fuel-cell vehicles in temperatures below the freezing point. The vehicle’s architecture is optimized so that it will start at -30ºC (-22ºF).

Looking Deeper into a Fuel Cell

The main elements of a fuel cell are the membrane electrode assembly (MEA), gas diffusion layer (GDL), and catalyst. Hyundai Motor Company developed its own MEA and metallic separator. Producing key components of the fuel stack itself resulted in lower production costs and enhanced vehicle capabilities, according to the company.

The MEA contains the materials necessary to facilitate electrochemical conversion of a fuel-to-electrical energy. It consists of a polymer electrode membrane with electrodes on either side. Hydrogen enters on one side (anode), where it reacts with a catalyst and separates into protons and electrons. The protons pass through the membrane to the other electrode (cathode). Here, they combine with oxygen and, with the help of a catalyst, produce water.

The electrons, which can’t pass through the membrane, flow from the fuel cell and are used as electrical energy.

The main function of the GDL is to provide conductivity, and help gases come in contact with the catalyst. GDLs are commercially available in various forms, such as carbon paper or woven carbon fabric. These are placed on either side of the membrane in the fuel cell. The greater surface area provided by the GDL increases transportation of electricity from each individual catalyst site in the MEA to the current collectors.

More Enhancements

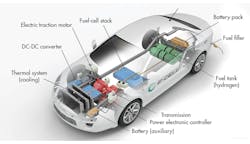

2. Shown are the components of a typical hydrogen fuel-cell-powered car. (Source: U.S. Department of Energy)

This next-generation hydrogen vehicle makes significant improvements in tank storage density, too. The tank package now features three equally sized tanks, as opposed to two of different sizes. Higher tank gravimetric capacity (hydrogen storage mass per tank weight) was achieved through innovations to the plastic liner configuration and an efficient layering pattern, which resulted in a reduction of thickness (Fig. 2).

To maximize efficiency in converting chemical energy into electricity, Hyundai Motor Company also introduced a new purification technology for air going through the humidification device and the fuel-cell stack GDL. The technology is said to have a purification ability of between 97% and 99% for PM-10 and PM-2.5 particles. PM-10 is particulate matter that’s 10 µm or less in diameter; PM-2.5 is particulate matter 2.5 µm or less in diameter. PM-2.5 particles are generally described as fine particles.

The new FCEV inherits design features from the Hyundai FE Concept, which was introduced at the 2017 Geneva Auto Show. Low-drag aerodynamic elements accentuate the design. The door handles sit flush to the car, while the air curtain—in conjunction with the air tunnel inside the D-pillar—maximizes aerodynamic efficiency. The SUV’s wheel design aims to capture both style and optimized low drag airflow with a specialized two-piece construction.

A wide dashboard and high console reinforces the SUV-style driving position and incorporates ergonomically designed controls and AV display screen (Fig. 3).

3. Multi-function displays are designed to minimize driver distraction.

Future Plans

Hyundai Motor Company is going to formally introduce its second-generation FCEV and unveil its official model name at CES 2018, which will be held in Las Vegas in January. The company plans to offer test drives in vehicles combining FCEV with self-driving technology. “We are planning to demonstrate the self-driving technology of our FCEV on highways early next year,” says Lee Ki-sang.

Hyundai Motor has supplied fuel-cell vehicles since 2013, and now sells them in 18 countries around the world. For its new FCEV, the company has prepared a mass-production system for fuel cells in Chungju, Korea, a city in North Chungcheong province and home to Korea’s National University of Transportation.

To meet Hyundai Motor Group’s goal of introducing 31 eco-friendly models (Hyundai Motor and Kia Motors combined) to global markets by 2020, the company also aims to establish an electric-vehicle (EV) lineup ranging from small EVs to large, luxury market Genesis-brand models. Electric-vehicle development will take place in multiple phases:

- Launch of the EV version of the Kona compact SUV, with a range of 390 km in the first half of 2018.

- Launch of the Genesis EV model in 2021.

- Launch of a long-range (500 km) EV after 2021.