During a recent press conference at Samsung’s Seoul, South Korea headquarters, the company revealed the findings of its investigation into well-publicized reports of its Note 7 smartphones catching fire. In a very technical, in-depth presentation that lasted almost an hour, the cause of the fires was definitively traced to the phones’ batteries.

In addition to Samsung’s investigation, three independent companies—UL, Exponent, and TUV Rheinland—had been brought in to do their own investigation. Representatives from all four firms were on hand for the presentation, and their conclusions were in agreement. Koh Dong-jin, president of Samsung’s mobile division, explained how engineers reached their conclusions (Fig. 1).

Samsung’s studies included aspects like hardware, software, and related processes (e.g., assembly, quality assurance, testing, and logistics). The company’s engineers also conducted tests with fast-charging features turned both on and off, used wired and wireless chargers methods, and conducted tests for charging/discharging without the back cover.

In addition, the engineers tested the electrical current used with the iris scanner and ran electrostatic tests to determine whether the USB Type-C was the cause of the problem. They even ran software algorithm analysis to see if pre-loaded and downloaded third-party applications were causing excessive current drain. Samsung claimed that none of the tests mentioned before showed any abnormalities.

The company also replicated the incidents in the field by creating a test facility for thorough battery analysis, where more than 200 thousand devices and 30 thousand batteries were analyzed. The devices and batteries were subjected to repeating charge/discharge testing for Battery A (first recall) and Battery B (second recall). Similar occurrences to those claimed by Samsung Note 7 users were found, indicating that the cause of the fire was in fact the battery itself.

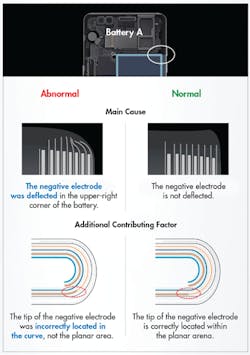

When charge/discharge tests were ran, the engineers found that Battery A has a deflection of the negative electrode that consistently occurred on the upper right corner of the jellyroll (Fig. 2). Also, incorrect positioning of the negative electrode tip had caused the negative electrodes to bend.

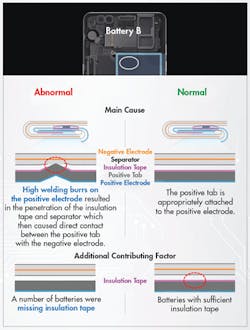

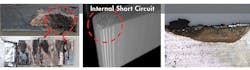

When Battery B was analyzed, Samsung’s engineers consistently found melting copper on the negative electrode area facing the positive tap. Therefore an internal short circuit was generated as a result of abnormal welding process resulting in a direct contact with the negative electrode (Fig. 3) producing thermal failure. In addition they found that some batteries were missing insulation tape, increasing the possibility of an electrical short circuit.

As for the third-party investigations, they did not find any battery system design that could have triggered the battery failures. Nor did they find any danger affecting battery safety integrity in the factories during assembly. TUV Rheinland also investigated their integrity during road transport between their warehouse in China and sub-assembly line in Vietnam.

In summary, the consensus opinion was that design and manufacturing issues with the batteries were responsible for the Note 7 device fires (Figs. 4 and 5). It appears that a very unlikely event had happened: the malfunction of two different Li-Ion batteries in a row.

In a post I wrote about the initial Note 7 incident, I mentioned the risk that companies take to rush test and validation procedures in order to be first-to-market. In addition to announcing the cause of the fires, Samsung also debuted an enhanced battery design and manufacturing process. The company has enhanced existing procedures and implemented new safety tests, creating an “8-point battery safety check.” The new safety tests are as follows:

- Charge/discharge Test: The batteries undergo a large-scale charging and discharging test.

- Total Volatile Organic Compound (TVOC): Additional testing to make sure there isn't the slightest possibility of leakage of the volatile organic compound.

- Accelerated Usage Test: intensive test simulating accelerated consumer usage scenarios.

Additionally, Samsung formed a battery advisory group of external advisers made up of academic and research experts, ensure that the company maintains a clear and objective perspective on battery safety and innovation. Members include Clare Grey, Ph.D., professor of chemistry, University of Cambridge; Gerbrand Ceder, Ph.D., professor of materials science and engineering, UC Berkeley; Yi Cui, Ph.D., professor of materials science and engineering, Stanford University; and Toru Amazutsumi, Ph.D., CEO of Amaz Techno-consultant.

Not everyone agrees with initiative, however. “Most of the Samsung 8-point tests are standard in the industry. What is more important are their internal safety processes and maintaining increased safety focus over time” said Nadim Maluf, CEO of Qnovo. “The Note 7 failure rate was less than 50 parts-per-million, but the consequence was measured in billions of dollars.”

“Our opinion is that manufacturing screening alone is not sufficient to avoid similar issues with small statistical failure rates in the future,” Maluf continued. “Battery safety can only improve through implementation of real-time control systems that can identify unsafe conditions during device operation as they evolve, and take proactive steps to shut down devices before they represent a safety hazard.”

While I am impressed that Samsung came forward and explained in detail what had happened with the Galaxy Note 7, it obviously would have been better if they had avoided the circumstances that led to the fires in the first place. Still, the company’s actions are a good first step toward earning back the trust of consumers.