This was an interesting week that included a trip to Phoenix to check out Solidworks World 2015. This might seem like the realm of our sister publication, Machine Design, but I found it to be very useful for me and our audience because of the range of technologies on display, from 3D printers to integrated PCB design tools.

I will get to some of the stuff I saw at the show, but first I wanted to touch on one of the more interesting and entertaining presentations I attended. The presentation (Fig. 1) was done by Stephen Endersby, a product manager at Solidworks, based on his recent blog entitled Solidworks Simulation Zombie Apocalypse Survival Kit.

The presentation is about Solidworks’ simulation support and how it could be used in checking out a zombie apocalypse survival kit. It would not be a great idea to test it in the field without first running some simulations. Even simple things like figuring out how many boards should be used to keep a door shut when zombies come calling will be useful, since there will not be unlimited resources available and it does get tiresome whacking off zombie heads using a Halligan tool (see Under a Graveyard Sky).

In any case, doors are often flexible and door jambs and nails are possible points of failure. Figuring out the loading is something that can be done using Solidworks simulations. Red, in the simulation, means bad, so red with zombies around means dead.

Bottom line, four planks of wood with 24 nails per door will do the trick. Of course, the rest of the house needs some simulation as well.

Advanced Workstations

I will be taking a look at MSI’s workstation-class laptops later along with AMD’s FirePro video adapters, but one that I wanted to mention now is Lenovo’s P-series ThinkStations (Fig. 2). PC workstations are the norm for Solidworks users as well as PCB designers and software developers. They tend to be designed with high performance and easy maintenance in mind.

The P-series looks distinctive because of the red bars on all the tool-less, adjustable spots such as hot-swap drives and removable fans. There is a significant lack of cables. The approach allows users a choice of three power supplies that just snap in place. The system also employs cooling baffles that can provide a dual-chip system with unique cooling paths for each chip.

The system also has a Flex connector for PCI Express and riser card. One card can hold a pair of M.2 flash memory cards. This allows flash drives to be used without taking up a PCI Express slot or a disk-drive bay.

PCB Design

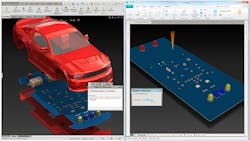

Altium’s PCBWorks is designed to be paired with Solidworks (Fig. 3). This combination streamlines overall system design. Mechanical, electrical, and electronic engineering change orders (ECOs) are reflected immediately, allowing design rules to be checked. Designers can use the collaboration tools to determine what changes will be utilized.

Even small changes like moving a mounting hole can have a significant impact. Other systems often require manual data exchanges between dissimilar systems leading to error-prone procedures. This process also takes time and not all systems provide easy-to-use tracking mechanisms.

PCBWorks brings Altium’s PCB design tools into close collaboration with Solidworks. The Solidworks plug-in provides a user interface for tracking changes, and PCBWorks uses the Solidworks API to exchange changes in real time.

The tight interaction allows features that would not be possible with simple file-import procedures. For example, copper information from the PCB design allows Solidworks thermal, EMI, and power integrity simulations. The system has Parasolid support.

The system is very useful when doing design for manufacturing (DFM). Layout, component, and other changes can improve DFM, but they can have an impact on the mechanical and PCB designs.

Prototyping Services

3D printers are great and often affordable. The problem is that they tend to be limited in functionality compared to possible construction methods. Likewise, 3D printers are great for creating single instances of an object,t but they tend to be slow and expensive when cranking out hundreds of objects.

Developers can turn to companies like Proto Labs for fast turnaround of items that might require special materials or construction methods. They can use techniques like injection molding or milling that are more applicable as the number of required items increases.

Their latest service is additive manufacturing. Proto Labs was handing out rings (Fig. 4) to highlight this service. The rings are plastic printed using a stereolithography 3D printer. They were then covered with a nickel-copper plating. The result is a lightweight, durable object that can be very complex and created at a low cost.

3D Printing with Paper

3D printers have cut costs significantly, but the printers and consumables are not cheap. Mcor Technologies’ new IRIS printer (Fig. 5) is an interesting alternative to conventional 3D printers that use materials like plastic or metal. Instead, Mcor’s solution uses a ream of paper.

Just imagine an object that fits inside a stack of paper. The object is actually laminated, with the surrounding paper scored so it can be easily removed. The system essentially builds up the object one sheet of paper at a time. Glue is applied to areas inside the object. A knife then scores the areas outside the object. The scored material falls off or is peeled off when the process is complete.

The cost is significantly less because at this point paper is cheap. Another advantage is that the system supports full-color objects. This trick is done by printing on the paper using a special printer and inks. These are designed so the color soaks through the paper versus conventional inkjet printers where the ink is designed not to soak through so it is possible to print on both sides of the paper.

Each printed page has a barcode that is read when printing to make sure all the pages are in the proper order. Solid-color objects can be printed without this step, using paper of the desired color. It is possible to make flexible objects as well as coating an object when it is complete.

The printer has a five-figure price tag. The material cost and time savings need to be balanced with the upfront costs—overall, a really neat approach.

This is not all that I saw at the show, but the rest will have to wait until later. In the meantime, I think I will read up on zombies by rereading Under a Graveyard Sky by John Ringo over on Baen Books.

About the Author

William Wong Blog

Senior Content Director

Bill's latest articles are listed on this author page, William G. Wong.

Bill Wong covers Digital, Embedded, Systems and Software topics at Electronic Design. He writes a number of columns, including Lab Bench and alt.embedded, plus Bill's Workbench hands-on column. Bill is a Georgia Tech alumni with a B.S in Electrical Engineering and a master's degree in computer science for Rutgers, The State University of New Jersey.

He has written a dozen books and was the first Director of PC Labs at PC Magazine. He has worked in the computer and publication industry for almost 40 years and has been with Electronic Design since 2000. He helps run the Mercer Science and Engineering Fair in Mercer County, NJ.

- Check out more articles by Bill Wong on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter