The development of no-clean fluxes and soldering pastes has done much to turn attention away from the need to clean components in electronics manufacturing. For many components that are only used in non-critical atmospheric environments, this poses no problem.

Related Articles

- Cleaning Kit Keeps Components Clear And Germ Free

- Flex Cables Suit Clean Apps

- Static Eliminator Neutralizes And Cleans Wide Surfaces

When these substances are used in adverse environments, though, the protective layer applied in the no-clean process can gradually erode, releasing ionizing substances that promote electro-migration and dendritic growth. This occurs mainly in narrow spaces beneath components and between their connections or other contact surfaces.

Protective coatings, progressive miniaturization, wire bonding, and the increased use of high-voltage components all call for a high level of surface cleanliness. But lead-free solders that may contain a higher proportion of fluxes and more aggressive activators can cause problems.

Also, the cleaning of electronic components involves removing potentially hazardous impurities such as fluxes, residues of soldering agents and adhesives, and dust and residue from previous manufacturing stages.

Choosing The Right Cleansing Agent

A key factor in achieving economy and efficiency in the cleaning process is the selection of a suitable cleansing agent. Criteria include the nature and quantity of the impurities to be removed and the subject material.

Cleaning agents currently used in electronics manufacturing include solvents, water-based media containing alkaline surfactants, and water-based tenside-free materials.

The electronics industry mainly uses solvents with non-halogenated hydrocarbons, modified alcohols, or hydrofluorethers (HFEs). HFEs were developed as an alternative to the previously preferred chlorofluorocarbons (CFCs) after CFC manufacture was stopped about 20 years ago due to their potential for breaking down ozone.

Non-inflammable HFEs are similar to CFCs, but pose no danger to ozone, do not persist in the atmosphere, and have low environmental impact. They offer physical properties that are in demand for electronics cleaning, such as relatively high density, low viscosity, and low surface tension. These solvents are used in monosolvent, cosolvent, and bisolvent systems.

A monosolvent system usually uses a pure HFE or an azeotrope, a mixture of two or more components that vaporizes without changing its chemical composition. It is used to remove slight impurities such as light oils, halogen compounds, particles, and dust.

The cosolvent system consists of an HFE combined with a low-volatility organic solvent as a solubility promoter. The solubility promoter removes impurities from the surface of the work piece, and the HFE rinses away the solvent and the impurities from the components.

Cleaning by cosolvent procedure is extremely versatile. It also yields good results with the most stubborn impurities such as heavy oils, grease, waxes, NC-flux residues, adhesives, and hot-melt glues. A low-volatility organic solvent allows material compatibility to be tested as well.

The solvent and the rinsing agent are mixed together in the cosolvent system, whilst they are kept separate in the bisolvent process.

Process Optimization

To ensure efficient and reproducible cleaning, the cleaning agent must be matched to the plant technology. That is why so many different cleaning systems are available, such as dipping plants with ultrasound or pressure flooding and spray cleaning plants. Solvents are used today in totally enclosed cleaning units.

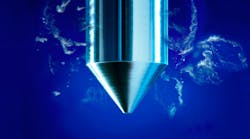

Ultrasound cleaning with solvents or water-based media offers a wide range of applications in electronics manufacturing (Fig. 1). In addition to the cleansing agent, the frequency of the electrical signals from the ultrasound generator influences the cleaning action, converting the oscillating system to sound waves in the fluid bath.

In general, the lower the electrical signal frequency, the greater the energy released by the sound waves. There are multi-frequency systems that permit acoustic irradiation of the goods to be cleaned at different frequencies. The optimum combination of cleansing agent and ultrasound frequency can be determined from cleaning tests, carried out by the suppliers of the equipment or the cleaning agent.

The type of cleaning equipment that will be used depends on three factors. What throughput must be handled? What space is available in which to set up the equipment? And, how can the cleaning process be integrated into the manufacturing chain?

Dry Alternatives With Carbon Dioxide

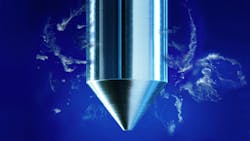

Cleaning with compressed carbon dioxide extends the wet-chemical process. The term “compressed carbon dioxide” indicates CO2 that has been converted to liquid form (that is, into its supercritical phase) under pressure. In this form, it possesses excellent properties as a solvent upon a range of non-polar impurities such as grease and oils.

Supercritical CO2 has low viscosity and low interfacial tension, resulting in improved ability to penetrate crevices (Fig. 2). This enables the cleaning of components with highly complex geometries such as tiny drill holes and the narrowest of cracks.

In electronics manufacturing, this technology offers the ability to clean such items as complete printed-circuit boards (PCBs) and assemblies, removing flux residues, and cleaning away oils and grease from metallic components such as contacts. It meets the requirement for an environmentally friendly, dry, and residue-free procedure.

Liquid carbon dioxide is also used as the medium in CO2 snow-jet cleaning, in this case in the form of minute snow crystals. With its combination of chemical, thermal, and mechanical properties, the non-poisonous and non-inflammable CO2 snow removes surface films and particulate contamination leaving no residue. It also can be used selectively on functional areas such as contact points. Since the cleaning is itself a dry process, there is no need for an energy-intensive subsequent drying procedure.

The procedure is employed in the most diverse applications in electronics manufacturing, such as the preparation for bonding processes, equipping PCBs and foil-PCBs, and the manufacture of metal-insulator semiconductors (MISs) to allow custom-tailored and reliable manual or fully automated cleaning.

Double Function Plasma

Plasma, a gaseous mixture of atoms, molecules, ions, and free electrons, allows efficient surface treatment of electronic parts and components of different materials, simultaneously cleaning away organic impurities such as oils and grease and activating the surface (Fig. 3). This double function is based on a physical and chemical reaction during the procedure.

Depending on the application in question, low-pressure plasmas or inline-capable atmospheric pressure plasmas can be used. With low-pressure plasmas, oxidizing and reducing processes both can be carried out. An oxidizing plasma can clean away organic contaminants such as grease, oil, and adhesive residue prior to soldering or bonding.

A reducing plasma process can be used, for example, to improve bonded connections by reducing electro-plated metallic layers. The electronics industry uses surface cleaning and activation by atmospheric pressure plasmas in such tasks as pre-printing, bonding, or casting of electronics boards and semiconductors, manufacture of opto-electronic components, and prior to wire-bonding.

Doris Schulz studied at the Fachhochschule für Wirtschaft, Gestaltung und Technik, Germany. One of her specialties is the field of surface treatment.