Altium has well-known electronic computer-aided design (ECAD) tools to handle PCB design. The challenge with system designs is that mechanical CAD (MCAD) tools are needed to handle the other aspects of the solution. Typically, developers using these two tools will work together by exchanging emails, files, change notes, and headaches. Using an integrated system could greatly simplify the process if it provides bidirectional communication so that changes can move through the system.

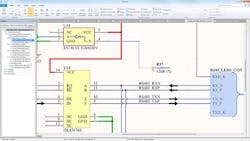

Altium PCBWorks (Fig. 1) provides this type of tight, bidirectional integration with Dassault Systemes SolidWorks, a major MCAD solution (see “Today’s Intricate PCB Design Needs Evolved Tools” on ). Altium’s PCBWorks is based on Altium Designer, a PCB design tool that handles 3D board design. It can handle the latest differential layouts for high-speed serial interfaces (Fig. 2). This includes interfaces like PCI Express, Serial ATA, and USB 3. PCBWorks can also handle some 3D design chores like highlighting 3D clearance errors. These are typical features for high-end PCB layout programs.

The difference is the integration with SolidWorks. PCBWorks shares access to the SolidWorks database allowing Engineering Change Orders (ECOs) to be exchanged. For example, enlarging a board or adding components on the PCB design side will be moved to the SolidWorks side. This level of integration required a good deal of cooperation by Dassault Systemes.

A typical scenario would be a SolidWorks designer dealing with a mechanical simulation and discovering that something like the mounting hold on a circuit board is causing a problem. The fix may be simply enlarging the hole or moving it slightly. Of course, this “minor” change could be significant because that movement could require a major redesign due to differential pair traces that would need to be adjusted as well.

The SolidWorks change would be fed back to PCBWorks where a designer could see the implications of the change. Actual scenarios tend to be more complicated and the affect can be significant as can the amount of information that needs to be exchanged. This includes version control and collaboration information, which is why there are social-collaboration tools incorporated into the system. Comments can include reasons why a particular change was needed or how it was made. This interaction can be key because often alternatives are included and changes are not finalized until all parties agree.

SolidWorks simulations can take an entire system into account and simulations can address a range of areas like as thermal, EMI, power integrity, and mechanical vibration. PCBWorks supports SolidWorks Parasolid models. This provides detailed board-assembly support. Another advantage of the integrated, bidirectional exchange is that there is no loss of data integrity that might otherwise occur with simple file exchange.

Not everyone can take advantage of PCBWorks since SolidWorks must be part of the mix, but this still leaves a large part of the market. The improved design cycle and reduction in errors due to manual integration make the combination highly desirable.