Display technology is inseparable from our modern world. From "retina" screens on the latest iPhones to 4K HDTVs and watches with OLED technology, today's consumer-facing electronics feature incredibly bright and detailed displays. However, this rich graphical experience has come at the cost of high power consumption. Be it a smartphone, tablet, or laptop, the component with the highest power requirement is almost always the display.

So when it comes to the Internet of Things (IoT), where battery-powered devices are central to many applications from manufacturing, to agriculture, to retail, power-hungry TFT LCD displays are out of the question. These industrial applications simply don't have the power budget for it.

But many IoT applications can still benefit from a way to give direct feedback to the user without having to go through the cloud. Whether it's a water or electricity meter that shows usage directly on the device, an RFID logistics tag, or a cold-chain temperature sensor, the addition of an onboard display can significantly boost functionality and value. In other areas, such as retail shelf labels, onboard displays open up new possibilities.

In these cases, where traditional thin-film-transistor (TFT) LCD displays are ill-suited to the requirements of the IoT, bistable display technologies —and e-paper in particular— has the power consumption, and display characteristics, that could make it the perfect match for the IoT.

Unveiling Hidden Value in the IoT

Whereas our consumer electronics, like desktop computers, smartphones, and tablets, are human-facing devices focused on rich interactive experiences, the IoT is characterized by cloud-facing devices, many with an emphasis on efficiently delivering environmental information. Optimized for the demands of a specific medical, logistical, or industrial environment, they're often designed to be compact, mobile, and battery-powered.

In the pursuit of battery life, many devices in the IoT, from industrial sensors to wearable glucose monitors to RFID devices, have eschewed traditional TFT displays. In purely machine-to-machine applications, losing a human readable display is no big loss. However, many IoT applications today, especially those with a human interaction element, can benefit from an onboard display.

Onboard displays can add value in a host of IoT applications. Examples include metering applications that show usage on the device without having to go through the cloud, RFID logistics tags with shipping information displayed directly on the tag, or glucose monitors that show blood sugar levels without the user having to power up the smartphone.

Ultra-Low-Power-Consumption Displays

While using TFT LCD displays for many IoT applications is unfeasible, the particular kind of data that most IoT devices handle — state information — suits them for bistable display technology. Bistable display technologies, and e-paper in particular, retain image information without consuming power. Power is used only when updating an image. In addition, e-paper is a reflective display technology that doesn't depend on a backlight for visibility.

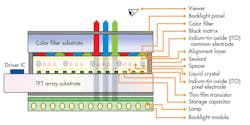

In a TFT LCD display (Fig. 1), light passes from a backlight module through a twisted nematic liquid layer. An appropriate charge is applied by the TFT to untwist the crystals in the appropriate configuration, and an image is formed by the light that passes through.

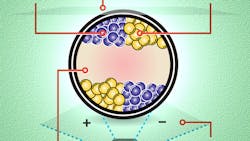

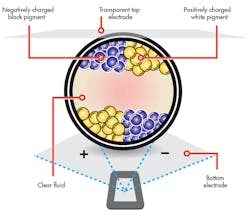

In an e-paper display (Fig. 2), millions of tiny capsules contain black and white ink particles. A charge applied to the top and bottom of each capsule arranges the ink particles to form an image. No backlight is needed because the image is visible from reflected light, which means e-paper displays can be much thinner than TFT LCD displays.

With the backlight dominating the power consumption of TFT LCD display modules, and often overall device power consumption, e-paper displays also achieve considerable energy savings compared to traditional displays due to their reflective nature.

Once the backlight is eliminated, power usage is dominated by the screen refresh rate, where further power savings are achieved due to the bistable nature of the e-paper display. TFT LCD displays require continual screen refreshes to maintain proper crystal alignment. In an e-paper display, once the ink particles are arranged properly, they stay that way until the next screen update. No additional power is needed to retain the image.

These characteristics mean that for applications with less frequently updated screens, e-paper modules require orders of magnitude less power than equivalently sized TFT LCD displays. With power-optimized waveforms, eTC (external Timing Control) e-paper modules like those from e-paper provider Pervasive Displays consume as little as 2 mA of current during screen update operations.

In an application where a 2-in. display is updated six times daily, an e-paper display can use as little as 0.01 mAh of power per day, whereas the typical, equivalently sized, LCD display would use 720 mAh over the same period of time to show the same image. Over the course of a year, the e-paper display would consume 3.29 mAh, or less than 2% of a 220-mAh CR2032 coin cell battery, while the LCD display would use 262,800 mAh, well over 1,000 CR2032 batteries (Fig. 3).

Not every device is suited for e-paper. Devices that need to display very frequently changing data, or which need to be primarily read in poorly lit environments, thereby requiring a supplemental backlight, reduce the low-power advantage of a bistable, reflective technology. But for many IoT applications displaying state information that isn't constantly changing, e-paper allows for an incredibly low-power consumption display.

Low-Power Displays Designed for the IoT

The low-power attributes of e-paper displays allow them to be used in devices that couldn't otherwise afford a display, or to extend the battery lives of devices already using another display technology. E-paper is so low power in fact, that it can be powered via energy-harvesting methods. E-paper modules integrated into NFC or RFID devices are able to be updated purely by scavenged RF energy or solar-energy sources that would be insufficient for other display technologies.

Ultra-Low-Power Displays for Battery-Powered IoT Devices

The current design philosophy of many wirelessly connected IoT devices is to sacrifice interface elements to prioritize battery life. User-facing interfaces and displays are foregone, with the only connection to the outside world a communication link to the cloud—usually Bluetooth Low Energy, ZigBee, or a narrowband technology optimized for the IoT.

The trouble is, many IoT devices, from connected meters to RFID tags to smart cards, are still human facing to some degree. Eliminating the human interface impacts the user experience—users must go through a separate device and connect to the cloud to access any and all information about the device right in front of them.

For many of these battery-powered wireless devices, a properly integrated e-paper display can bring back display and interface aspects that add value to the device, with minimal impact on battery life.

This includes mirroring some of the information sent to the cloud, such as in sensing applications where values like blood glucose, water usage, or temperature are shown directly on the device. For more remote, less frequently accessed industrial IoT devices, the display can also show maintenance and debugging information, e.g., battery life, service life remaining, maintenance schedule information, or memory dumps in case of a crash (the bistable nature of e-paper means the memory dump will remain on screen even if power is lost).

It can also extend to more complex situations where data is sent both to and from the cloud. A smart payment card with an integrated e-paper display could interact with a payment terminal to both pay for a train ticket, and then display a downloaded image of the train ticket, including barcode, directly on the payment device.

No-Power Displays Using RF or Solar-Energy Harvesting

Perhaps the most intriguing use case of e-paper is that of a no-power display for batteryless devices (Fig. 4). With its ultra-low-power consumption requirements, e-paper can take advantage of energy harvesting to perform screen updates. Using solar power, RF energy scavenging, and other energy-harvesting methods, low-power IoT devices with e-paper displays can operate almost indefinitely.

Energy harvesting is a good way to integrate e-paper into RFID and NFC devices, as these devices are often already passively energized. The e-paper display can be driven by scavenged energy from the RF field used to update the device.

The display can supplement machine-readable data stored in the tag, such as shipping or manufacturing information, with a human-readable label that doesn't require a smartphone or specialized reader. The combination of e-paper and NFC also opens up new application possibilities, such as the aforementioned payment card with integrated display, ID badges, or updatable product information labels.

Solar-powered outdoor signage is another natural application of energy harvesting with e-paper. While LCD displays need strong backlighting to be visible in the sun, e-paper is extremely readable even under direct sunlight. This makes possible applications such as bus stops with solar-powered e-paper timetables.

Is There a Place for LCDs in the IoT?

TFT LCD technology, while much less power-efficient than e-paper, can be suitable for certain use cases in the IoT where rich, multimedia experiences are important, and power is more readily available.

LCDs could be considered for devices with less serious power considerations, most obviously those with access to mains power (e.g., wall-mounted thermostats), but also devices that may be expected to be charged daily (e.g., wearables). However, even for wearables, the value of the multimedia experience offered by the LCD should be weighed against the inconvenience of frequent charging, as well as the loss, or reduction, of functionality when the device is being charged.

Since it inherently incorporates a backlight, LCDs can also be appropriate when the device is often used in dimly lit environments. In these cases, while e-paper could still be utilized, a backlight module would have to be integrated, reducing the energy savings.

Because of their widespread use in consumer electronics, modern TFT LCD display modules are quite inexpensive, making them attractive for cost-sensitive devices. However, designers should also consider the price of the extra processing hardware required to drive an LCD display. Especially when it comes to higher-resolution displays, the cost of video memory, a higher-speed MCU, and an LCD controller may offset some of the cost advantage compared to e-paper.

On the downside, due to being a backlit technology, TFT LCD displays are thick, and have poor outdoor visibility. While advances have been made with the advent of LED-based backlighting, the need for a backlight module makes it difficult to slim down TFT LCDs.

Outdoor visibility of LCDs remains a challenge as it depends on the light coming from the display keeping up with ambient lighting. Whereas reflective displays reflect more light in bright environments, emissive displays like LCDs can only improve outdoor visibility by ramping up backlight brightness. The brightness of modern LED backlights is enough to let them perform admirably outdoors, as long as they stay out of direct sunlight. However, they do so at the cost of high power consumption.

Does OLED Technology Fit the IoT?

In recent years, OLED display technology has started to make its way into high-end TVs, music players, and even smartwatches. Compared to TFT LCDs, OLED displays have better contrast ratios and theoretically better power efficiencies. Are they a good fit for the IoT?

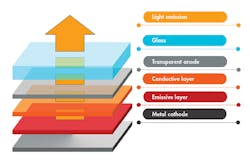

OLED displays work due to the electroluminescence of organic semiconductors when a current is applied (Fig. 5). A typical display will have a "sandwich," where electrodes surround a conductive layer and emitting layer of organic materials. When electricity is applied, electrons are deposited in the emissive layer and removed from the conductive layer. As electrons are removed from the conductive layer, the holes that remain are then filled by the electrons from the emissive layer, giving off light in the process.

Whereas the light from LCD displays originates from the backlight module, passes through liquid crystals, and then polarizing filters, an OLED’s organic layer itself produces light and doesn’t pass through polarizing filters. The lack of a backlight and filters not only enables OLEDs to be much thinner than LCDs, but also leads to better optical characteristics.

OLEDs are able to control brightness at the pixel level, allowing for pure blacks and high contrast ratios. Whereas some amount of backlight will always leak through on an LCD display, an OLED display can completely turn off the light from particular pixels. Without polarizing filters, viewing angles are also improved compared to LCD displays.

Another distinct advantage of OLED displays is that the organic materials used can be deposited on a plastic substrate to create flexible displays for devices with unique form factors. This is most vividly demonstrated on Samsung's Galaxy Edge series of smartphones, which have a 90 degree curve in the display at the edges of the phone. This combination of flexibility and thinness is particularly enticing for wearables, such as smartwatches; indeed, the Apple Watch uses an OLED display.

While optically superior to LCD displays, OLED displays do have their disadvantages. OLED technology currently costs 20% to 30% more than similar TFT LCD displays; power consumption is only marginally better; outdoor readability is about the same or worse; and the technology has lifespan and durability issues, especially for industrial use cases.

Since brightness is controlled at the pixel level, power consumption in an OLED display depends on the brightness of the image. Darker images and black backgrounds can result in better power consumption than TFT LCD displays, but bright images and white backgrounds in particular can lead to more power usage than TFT LCD technology.

Both LCD and OLED technology suffer when outdoors. However, the brightness of current OLED displays hasn’t matched the level of LCD backlights, meaning outdoor visibility is even worse. The organic materials used in OLEDs are also extremely sensitive to water. Combined with poor sunlight readability, this makes OLEDs a poor fit for outdoor applications and industrial environments.

Finally, OLEDs have lifespan issues. This is especially the case with the material used for blue light—it’s subject to degradation over time, leading to significant color shift well before the lifespan of an average TFT LCD display.

Using electroluminescence of organic materials rather than backlighting, OLEDs are a promising display technology. Their flexibility, thinness, and strong contrast make them a strong contender for wearable applications. However, sensitivity to water, short lifespan, and power consumption when compared to LCD displays means their use in the IoT is limited to devices with waterproof enclosures or in controlled environments, and where frequent charging can be expected.

Making the Low Power IoT Visible

As the IoT affects more industries, the amount of real world data being sent to the cloud is greater than ever before. Still, a lot of this high value information is hidden from direct view. Many of these applications can benefit from a display that shows information to users directly on the device.

The increasing use of TFT LCDs and OLED display technology in consumer electronics, and their rich multimedia capabilities, makes them tempting to use in industrial and IoT applications. However, their power requirements make them less than ideal for the often battery-constrained IoT.

With power consumption orders of magnitude less than TFT LCD or OLED displays, e-paper can be used on IoT devices without the power budget for other display technologies—it even allows for no-power displays that work purely off of harvested energy. Since much of the IoT deals with infrequently changing state information, e-paper technology with its bistable, reflective benefits is a perfect fit.

About the Author

Scott Soong

CEO

Scott Soong, CEO of Pervasive Displays, has over a decade of experience in software in addition to 12 years working in displays businesses. During his career, Scott has been a founding partner at four startup companies, including Pervasive Displays. Scott sits on the board of several other technology businesses as a consulting partner. He was a board member of One Laptop Per Child (OLPC), which looks to provide kids in developing countries with a rugged, low-cost, low-power, connected laptop.

Scott received an MBA from the Haas School of Business at the University of California, Berkeley as well as a BA from the University of Michigan at Ann Arbor.