Q&A: Vesper’s Chief Executive Lends an Ear to the Internet of Things

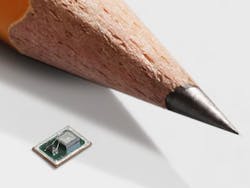

Vesper is making sensors to do just that. The company builds tiny microphones that exploit the piezoelectric effect to achieve extremely high sensitivity and durability. It is betting that microphone arrays will become one of the most popular ways to interact with smartphones, household devices, and smart speakers like the Amazon Echo and Google Home.

The early signs are encouraging. Vesper partnered with GlobalFoundries last year to produce its first product – the VM1000. It also struck deals with China’s XinGang and ACC Technologies to ship its microphone wafers into smartphones and smart home devices. In the pipeline are low-power microphones that never stop listening and that "zoom" into certain sounds.

Matt Crowley, Vesper's chief executive and one of its founders, discussed the company’s piezoelectric MEMS and microphone applications that still surprise him. This interview has been edited and condensed.

What was the impetus for forming Vesper?

Our thesis is that voice interfaces are going to become very popular. One of the things holding them back is accuracy and really good far-field processing in noisy background environments. To make a really good interface, you need an array of microphones working together with beam-forming.

Microphone arrays are more commonplace and companies are trying to roll them out in products like the Amazon Echo. In the future, there are going to be microphones and sensors in virtually every product. But in the coming years, we’ll focus on mainstream things like smart speakers, smart watches, hearables, and drones.

Vesper is a little unique: It makes MEMS microphones based on piezoelectric materials instead of capacitive sensors. What are the benefits of that approach?

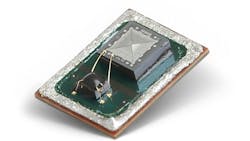

Piezoelectric MEMS have a lot of advantages. First of all, our product has a much simpler structure. It’s a single layer diaphragm, where capacitive structures have two layers – a diaphragm and back-plate. And that leads to reliability problems. Because we don’t have the tiny capacitive gap where water or particles can get trapped, our product is totally immune to water, dust, and vapors.

Another advantage is that it doesn’t require a bias voltage from a charge pump. We also have much faster startup times, so people can duty-cycle the microphone if it’s in listening mode and save more than 50% in power consumption.

The device also has a lower noise floor. Because it’s a single layer, we don’t have squeeze film damping, which happens when the air between the capacitive back-plate and diaphragm forms a stiff mass that resists motion. That air pushes back on the capacitive diaphragm and that creates damping. With ours, there’s nothing to impede its motion, so you get a high SNR [up to 68 db in its available sensors].

But you are also exploiting the piezoelectric effect.

One other thing we can do is called “quiescent sensing.” This, we think, is a whole new category of MEMS device. When you take a piezoelectric crystal and bend it – the motion creates a voltage. What we did is harness that effect to create a microphone that generates electricity directly from a sound wave. And it generates enough to actually turn itself on.

The practical application for this is the wake-on-voice microphone, which only consumes power when it hears a sound. There are devices today like smart television remotes and smart speakers that require a button to turn on and then you can talk to them. With wake-on sound, you don’t need that button at all.

So then what’s the importance of SNR?

I’ve asked some software guys, “What do you think about high SNR? Is it a big deal?” And they said, “Look, if we have a microphone with 65 db SNR that feeds data into a system operating at a much higher SNR level, the microphone becomes the bottleneck for interesting signal processing.”

Does having high SNR, which increases sensitivity, place more responsibility on the software to wring the right sounds out of the environment?

It sort of does. But the state of the algorithms is that they are ahead of the physical interface of the microphone. The software people – it’s almost like they have this Ferrari engine with Yugo tires. The microphone is definitely the laggard in the whole signal chain.

How do all these different capabilities play into voice interface applications you mentioned?

The play that piezoelectric MEMS have into the array market is the low power consumption. It also goes back to what I mentioned about the resistance to water and dust. The problem with arrays is that they’re single point-of-failure devices, so if you have one microphone fail, the whole array doesn’t really work properly anymore. In some ways, you are worse off than just using a single microphone.

Are there applications for microphone arrays that the average person might be surprised to hear about?

There are. It’s mostly using quiescent sensing to do event detection. We’ve been contacted, for example, by furniture companies that want to place microphones all around a person’s office and home. There are a lot of health and medical applications, with microphones being worn by patients to monitor their breathing and coughing.

Some people want to put microphones on the outside of cars to listen for horns and warn drivers about cars coming up behind you. We have a lot of security people who want microphones to react to certain events – breaking glass is a very common one. They can also be useful for detecting someone firing a gun. What kind of firearm was it, where the person is located, how many shooters were there.

Of course, people are putting voice activation into anything you can think of. It’s pretty wild the kind of inquiries we get.

You seem most excited talking about these new applications. Do you still get surprised by some of the calls you get?

You know, I do. Many of those things I never thought before. Someone says, “I want to put a microphone in the little plastic ear tag on every cow on my farm.” It’s just not the kind of thing you would think about. Some of it is far-out science fiction but a lot of it’s practical.

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.