Expanding CAN Bandwidth Poses Automotive Challenges

The volume of electronic content built into vehicles continues to increase at a remarkable rate. Major improvements in performance and functionality have been witnessed in key areas such as safety, comfort, the powertrain, infotainment, and lighting.

Some industry experts have predicted that by 2019, up to 50% of the overall cost of conventional (internal combustion engine) vehicles and 80% of the overall cost of hybrid vehicles will be due to their onboard electronics.

With more complex electronic control units (ECUs) being put in place, made up of ever-greater quantities of semiconductor components, ensuring that the various individual devices, modules, and subsystems are all able to communicate with one another effectively is critical. This is made all the more difficult due to the harsh operational environments that are endemic of this extremely demanding sector.

This file type includes high resolution graphics and schematics when applicable.

The Role of CAN

For many years, in-vehicle networks using the highly robust, asynchronous operating Controller Area Network (CAN) bus or other communication protocols, such as Local Interconnect Network (LIN), have been more than adequate in providing the necessary infrastructure over which rapid data transfer could be carried out.

As the volume and intricacy of vehicle electronics systems increase, though, the operational limitations of legacy networking protocols will start to become apparent. So, there is a corresponding need for higher-bandwidth network technology to be used, supported by the implementation of more advanced transceivers with a greater degree of functionality.

CAN Flexible Datarate (CAN FD) is at the vanguard of the next generation of automotive networking protocols that have emerged. Reliant on a dual-bit data-rate configuration, it offers automobile manufacturers the prospect of markedly increasing the bandwidth available within their latest models.

This protocol is based on a similar underlying architecture to the previous CAN incarnation, making it relatively easy to implement. It offers, however, the possibility of much higher speeds, thanks to an increased bitrate in the data phase and the possibility to send more data bytes (64 as opposed to just 8, which was previously possible).

Because of the simple migration path it provides, CAN FD also represents a relatively low cost per node compared to some of the other high-speed automotive networking protocols currently being considered.

State-of-the-art CAN transceiver ICs, with bitrates that are above 1 Mbit/s, can be used to support CAN FD implementation. The question is how these transceivers will be protected from the various sources of harm to be found in automotive application settings.

Protection Mechanisms Within CAN Nodes

CAN transceivers often will depend on the use of a number of external components for tackling the operational problems caused by:

• Electromagnetic emissions (EME), which can disturb the operation of other systems in the vehicle

• Electromagnetic interference (EMI), which will otherwise affect the signal integrity of data passing through the CAN network and thus bring about communication problems

• Electrostatic discharge (ESD), which could potentially lead to irrevocable damage of the constituent semiconductor devices

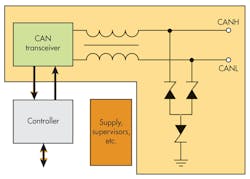

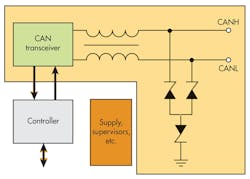

Inclusion of these external components will mean that reliable connectivity can be maintained. As a result, CAN communication nodes (see the figure) normally will comprise a CAN transceiver, a common-mode choke (for combatting EME and EMI), and an ESD protection device (usually some form of transient voltage suppressor).

The choke’s leakage inductance, along with the combined capacitances of the other external components encompassed within this setup, unfortunately will create resonance. In certain circumstances, resonance can heighten the bit error rate and cause the signal latency of the network to be detrimentally affected too. This was already a concern for standard CAN implementations. But with the advent of CAN FD on the horizon, the seriousness of this problem will be compounded.

There are other issues arising with regard to the use of external ESD protection devices that need to be addressed. Potentially, they can interact with internal ESD protection mechanisms that are integrated into the transceivers themselves, so their effectiveness can be compromised. Consequently, there are all manner of complications when selecting external protection devices to accompany particular transceivers.

Furthermore, the inclusion of such devices obviously takes up more printed-circuit board (PCB) real estate and requires greater levels of thermal management. It also raises the associated bill of materials costs and lengthens the development time needed. Effort must therefore be made to reduce the number of components necessary within each node.

What’s Next

By specifying more advanced, highly integrated semiconductor technology, it will be possible to implement CAN front-end communication nodes that consist solely of a transceiver IC. System-level signal integrity devices like external ESD still will have to be considered on a case-by-case basis.

Integration not only will be advantageous in terms of lowering the overall expense involved, it also will enhance the operational performance of the communication infrastructure by tackling signal-to-noise issues that stem from resonance effects.

Currently, there are 20 to 30 nodes in most automobile CAN networks, while 50 to 100 nodes can be found in the networks of some luxury models. These sorts of figures likely will be true for mid-range cars in the next few years. With this in mind, the weight reduction should also be considered beneficial.

CAN FD transceiver products starting to enter the market will help this protocol become more widespread. Still greater integration eventually will be afforded through implementations of devices where the CAN FD transceiver and the CAN controller are embedded onto a single chip.

By removing the need for the CAN controller function to be addressed via the system microcontroller, it will be easier to migrate existing automotive designs. ECUs can be redesigned without having to change the existing microcontroller for a new one that supports CAN FD. This still appears to be some way off, though.

Ensuring in-vehicle network robustness while achieving higher data rates will be critical in next-generation automobile designs. As we have seen, more sophisticated networking devices are now emerging that can meet the exacting technical challenges being set by car manufacturers as they strive for superior in-vehicle communications.

Jan Polfliet is the manager of ASSP, Worldwide Automotive Products, at ON Semiconductor. For more than 30 years, he has been involved in semiconductor engineering from process engineering to production manager, and now product marketing manager. Prior to joining ON Semiconductor in 2010, he was a product marketing manager at Alcatel Microelectronics, where he was responsible for defining, creating, and promoting ASSP products ranging from plain consumer products like DECT, GSM, and Bluetooth to more specific ASSP products like IVN transceivers and LED drivers for the automotive and industrial markets. He is a manager for ON Semiconductor’s worldwide automotive ASSP products. He received his master’s degree in computer science. And, he speaks Dutch, French, and English.

Lance Williams is the vice president of automotive strategy at ON Semiconductor. He joined the company in 2004 and leads its worldwide automotive marketing strategy. He brings more than 35 years of semiconductor and electronics industry experience to this position. Previously, he led ON Semiconductor’s Global Automotive Sales organization. Before joining ON Semiconductor, he spent most of his career with Motorola/Freescale in a variety of sales positions, including VP and sales director of North American Automotive, Delphi Automotive sales director, director of EMSI, and regional sales manager. This experience in automotive and semiconductor sales allows him to be perfectly suited for this new position, leading ON Semiconductor’s automotive strategy by driving a complete automotive business model within ON’s global infrastructure, while aligning ON’s strategies with key OEMs and customers.

About the Author

Jan Polfliet

Manager of ASSP, Worldwide Automotive Products

Jan Polfliet is the manager of ASSP, Worldwide Automotive Products, at ON Semiconductor. For more than 30 years, he has been involved in semiconductor engineering from process engineering to production manager, and now product marketing manager. Prior to joining ON Semiconductor in 2010, he was a product marketing manager at Alcatel Microelectronics, where he was responsible for defining, creating, and promoting ASSP products ranging from plain consumer products like DECT, GSM, and Bluetooth to more specific ASSP products like IVN transceivers and LED drivers for the automotive and industrial markets. He is a manager for ON Semiconductor’s worldwide automotive ASSP products. He received his master’s degree in computer science. And, he speaks Dutch, French, and English.

Lance Williams

Vice President o Automotive Strategy

Lance Williams is the vice president of automotive strategy at ON Semiconductor. He joined the company in 2004 and leads its worldwide automotive marketing strategy. He brings more than 35 years of semiconductor and electronics industry experience to this position. Previously, he led ON Semiconductor’s Global Automotive Sales organization. Before joining ON Semiconductor, he spent most of his career with Motorola/Freescale in a variety of sales positions, including VP and sales director of North American Automotive, Delphi Automotive sales director, director of EMSI, and regional sales manager. This experience in automotive and semiconductor sales allows him to be perfectly suited for this new position, leading ON Semiconductor’s automotive strategy by driving a complete automotive business model within ON’s global infrastructure, while aligning ON’s strategies with key OEMs and customers.