Electronics are getting smaller and showing up everywhere. Using Thinfilm's technology, electronics can be printed as well (Fig. 1). Thinfilm's printed memory label can be used for a range of applications including prevention of counterfeit products. This technology has expanded into other areas such as sensors and displays.

I spoke with Dr. Davor Sutija, CEO of Thin Film Electronics ASA, about their printed electronics technology including how it will affect developer's choices especially in this era of the Internet of Things (IoT).

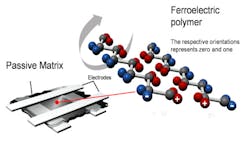

Thinfilm's memory technology puts a ferroelectric film between two electrodes (Fig. 2). The dielectric dipoles within the polymer layer align when voltage is applied. The alignment depends upon whether the voltage is applied to the top or bottom electrode. The non-volatile memory cell retains its state when power is removed.

Wong: Can you provide some background on Thinfilm and how it fits into the "printed electronics" space?

Sutija: Thinfilm is the only public company focused solely on “printed electronics.” Thinfilm’s first product was a printed memory label, which was the first of its kind – rewritable, non-volatile data storage on a 5-cent label. In addition to recently announcing a stand-alone sensor label made with Printed Electronics (see below for details), Thinfilm is currently working on adding additional functionality to its product line, including logic, display, and wireless communication. Thinfilm’s printed electronic labels bring simple electronic functionality into high-volume, cost-sensitive applications—areas like brand protection, packaging of perishable products, one-time-use medical products, and disposable consumer goods.

Related Articles

- Printable Storage Arrays

- Thin-film electronics to become multi-billion dollar market

- Printed-Electronics Technology Flexes Its Muscle

Wong: What's different about this system than comparable or existing technology that does the same function today?

Sutija: At the present time, traditional silicon systems that are comparable to Thinfilm in their functions are ten times as expensive and are non-scalable. It is practically impossible to use silicon chips on everyday objects since silicon scale with the number of people in the world. Thinfilm’s technology is scalable by the billions of objects in the world. By using a roll-to-roll printing method it is possible to print millions of labels at a time at a price point significantly lower than silicon.

Wong: How does the system work from a technological perspective?

Sutija: The Thinfilm Smart Label is equipped with memory, sensor, logic, display screen and battery (Fig. 3). The sensor picks up data, sends via logic to memory and the result is displayed on the screen. The label can tell the user whether for instance a certain temperature threshold has been exceeded or if there is a time sensor, the label will indicate when a certain time has passed. Depending on the customers´ needs, we can create different types of integrated systems.

Wong: What are the design challenges in developing the Thinfilm technology?

Sutija: There are many components to fit on a small label, so when we developed the standalone Smart Sensor Label, we had to make sure that the components were the right size so that they could be properly integrated. We also used logic for integration with components with different functional requirements and this was the real accomplishment in designing the label.

Wong: Has Thinfilm’s technology been deployed anywhere? What are the potential applications?

Sutija: Thinfilm has several partnerships with leading companies including the Bemis Company, largest flexible packaging company in the world, Brady Corporation, a leader in the high-value labels and personal identification markets, Hasbro in toys and games and a fast moving consumer goods company.

We also secured a commercial order for the Brand Protection Solution from an international luxury goods company who will begin using our Brand Protection Solution with rewritable memory in 2014 as part of its next major product release. The customer is a maker of high-end apparel and accessories and the Thinfilm solution will be used to provide both product authentication and assist in tracing grey market activity.

Wong: What is Thinfilm's outlook for the next year and beyond?

Sutija: Our current product is the Brand Protection Solution and in the near-term, we are working on the above mentioned Smart Labels which are integrated systems in which logic, sensors and display work together. Companies can tailor our labels to fit their exact needs. If you don´t need display, no problem. And, you can have more or less logic depending on the use of the label.

The Thinfilm Brand Protection Solution will be used to provide both product authentication and assist in tracing grey market activity. The International Anti-Counterfeiting Coalition estimates $600Billion is lost each year due to counterfeiting, and the World Customs Organization estimates that between five and seven percent of all goods traded on the global market are counterfeit. Thinfilm provides ultra-high security at a price point that is compatible with everything from high-end products to fast-moving consumer goods. These will be commercially available early in 2014 for anyone who wants to incorporate our technology into their products.

Now that we have the infrastructure, technology and ecosystem of partners in place the long-term play is about to mature in a number of other billion-dollar markets (supply chain, mobile, healthcare, retail, etc.). We are also enabling the Internet of Everything by making everyday items intelligent – this can be the catalyst to enable transformative hardware and software companies around the globe, saving companies millions of dollars in operational efficiencies. The Internet of Everything is poised for explosive growth in the next several years. Gartner projects there will be 30 billion connected “things” and more than 200 billion connections by 2020.

Wong: How does this enable the so-called "Internet of things"? What function does it serve in the big picture?

Sutija: Thinfilm has the potential to bring intelligence and communications to the billions of everyday objects in this world – even low cost perishable goods. This will allow objects to gather actionable data, and displaying and communicate it when we need to get involved. For example, Thinfilm’s technology can track the temperature of food in real-time. Adding just one percent to the retail value of industry segments like perishable goods, medical products and disposable goods is a $100 billion opportunity. And this is just scratching the surface.

Delivering a scalable, commercially viable smart label will enable the Internet of Everything and change the way people interact with the world.

Wong: What is the potential market opportunity for a company like Thinfilm?

Sutija: Our brand protection and smart label products are expected to have an impact on broad vertical markets, such as consumer packaged goods, health care, and retail.

Cisco CEO, John Chambers, says that the Internet of Everything could be a $19 trillion opportunity. The market opportunities scale not by the number of people in the world, but by the number of objects in the world.