MTBF And Reliability—A Misunderstood Relationship In Solar Photovoltaics

The solar photovoltaic (PV) industry is evolving to emphasize ways to enhance performance and reduce costs. The traditional approach of using central or string inverters (Fig. 1) with the highest efficiency under lab conditions, and at the lowest cost per peak watt of power, is giving way to systems that are simpler to install with longer component lifetimes, no central point of failure, greater flexibility in module positioning, and easier system monitoring.

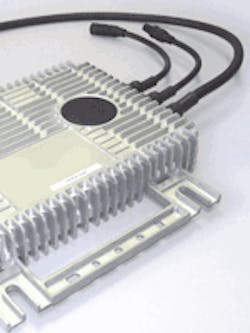

Systems based on micro-inverters (Fig. 2) harvest more energy in more diverse, real-world conditions. Here, the dc-dc conversion (Fig. 3) is carried out behind each PV module. As long life expectancy is a key requirement for such systems, the reliability of micro-inverters is being called into question.

THE MTBF MISUNDERSTANDING

One often-quoted measure of reliability is mean time between failures (MTBF). There is a common misunderstanding that a product with a high MTBF will last longer than a similar product with a lower MTBF. This simply isn’t true, and the high numbers that are frequently quoted add to the confusion. To illustrate this misunderstanding, the death rate for 25-year-old people is about 0.1% per year. This is equivalent to an MTBF of 800 years, but few of us expect to last that long.

The implication made by suppliers in the solar industry quoting high MTBF numbers attempts to support an expectation of a long life. Such statements are factually wrong. An MTBF of 600 years sounds great, but 100% of the products may fail in a short time. Failures within 10 years are common for solar inverters. This is because wear-out mechanisms determine the lifetime of products, and MTBF does not predict them.

Take a look at the MTBF basics. The so-called “bathtub” curve (Fig. 4) is the simplest reliability concept. It’s a simple graph showing how products first go through a phase called “infant mortality” where the number of failures over a given time is relatively high at the start. Things settle down for another period of time where failure rates are low. We’ll call this the “useful life” period.

After that, wear-out mechanisms kick in to increase the failure rate rapidly and the curve goes back up. The MTBF only provides a statistical indication of the failure rate that can be expected during the useful life period. It doesn’t say anything about infant mortality or wear-out mechanisms.

Most people would assume that they should buy a product that has an MTBF of 600 years instead of one with 300 years. The tacit assumption is that one is going to last twice as long as the other. However, the truth is that nothing about these numbers says how long they will survive before “wearing out.” The product with the MTBF of 300 years could live 40 years before the wear-out mechanisms kill it. By contrast, the product with 600 years of MTBF might have wear-out mechanisms that limit its life expectancy to 15 years or less.

If you know this, you would clearly choose the 40-year life expectancy product over the 15-year life expectancy product. For a solar micro-inverter, this is hugely important. You will replace all of your models with a 15-year lifetime before they wear out, which is about 25 years. Yet you will only replace a few of the products with the 40-year lifetime during those 25 years.

FURTHER COMPLICATIONS

The use of MTBF as any indicator of expected operating life is further complicated by the way in which it’s calculated. Remember, without decades of experience to call upon to measure MTBF, it is just a calculation based on a set of assumptions about the components used in the product. Different methodologies will use different sets of assumptions.

Data from the European Power Supply Manufacturers Association, an independent trade body, found that MTBF figures for the same product could vary by 10:1, depending on the methodology used in calculating them. This is further evidence that an over-emphasis on MTBF as a measure of real-world reliability is just marketing smoke and mirrors.

So what does it matter? The industry will increasingly see all suppliers of solar products provide accelerated life testing data borrowing from accepted tests and methods widely used in the electronics industry and essentially identical to requirements for solar modules, like IEC61215. Such tests provide real data to support meaningful predictions of useful lifetimes of products deployed in real-world conditions.

This is particularly important for the emerging micro-inverter suppliers, as micro-inverters have to operate outside exposed to full temperature and environment extremes, which are made harsher due to the heating effect of high solar energy falling on the modules. Temperatures can be as much as 50°C hotter on the back of a solar module.

Warranties offered by companies on their products will increasingly be in the spotlight. However, these warrantees only will be credible when data is supplied to support such claims. MTBF predictions do not constitute credible data for this purpose. The PV industry will benefit from longer warranties, but it’s critically important to provide the underlying body of accelerated life test data to support such warranty claims.