When we talk about a container-based data center in Norway’s Lefdal mine, we’re not talking about programming containers or virtual machines. No, we’re talking about 40-ft. Container Data Centers from Rittal that are filling the void left in the Lefdal mine (Fig. 1). It was the largest olivine mine in the world, but it’s no longer active, at least as a mine.

1. The Lefdal Mine Datacenter (LMD) is a project that IBM, Rittal, and Lefdal have built within the Lefdal mine in Norway.

The Lefdal Mine Datacenter (LMD) is a 120,000-m² site in Måløy on the Norwegian West Coast. Initially, it was set up for 300 containers and up to 45 MW of cooling output. The overall system may have up to 1,500 containers with a cooling output of up to 200 MW. IBM, Rittal, and Lefdal are partners in the project designed to provide an efficient, secure, cloud environment that’s extensible by adding more container-based compute, storage, and cooling systems.

LMD only uses renewable energy sources; it’s cooled by water from a nearby fjord. This approach reduces energy costs in addition to providing cost savings of up to 40% compared to a conventional cloud data center. The low-energy costs allow the overall system to achieve a PUE (power usage effectiveness) below 1.15.

2. Rittal’s RiMatrix S Standard Container is designed to be a data center in a box—a big box.

Its makeup makes it a secure location as well as providing a cool and dry place for containers like Rittal’s RiMatrix S Standard Container (Fig. 2). This platform was actually developed by Rittal specifically for the Lefdal project to better meet the high requirements for scalability, standardization and modularity. The RiMatrix S is available for use at other sites.

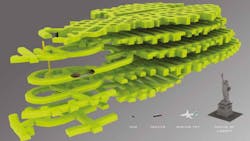

The modules can be stacked since there’s sufficient headroom in the vast mine (Fig. 3). The modular approach allows customers to choose the solutions based on pre-certified system components.

3. A multilevel container system takes advantage of the large corridors that measure up to 16 m high.

“With this project, we are showing how easy it can be for companies nowadays to construct a secure, efficient, and cost-effective data center in a very short time. This solution’s high degree of standardization, combined with the location advantages of the western coast of Norway result in an excellent TCO analysi,s” says Martin Kipping, Director International IT Projects, Rittal. “Planning by the participating project partners envisages that the first customers will be able to use their IT systems in the Lefdal mine productively as early as the fourth quarter of 2016.”

The mine is massive in scale (Fig. 4). Its entrances have physical security barriers to prevent unauthorized access. Trained security personnel are on site, and there’s a three-stage authentication process with an intelligent camera system to provide additional security. Furthermore, a sitewide fire-detection system was installed with local VESDA and fire-suppression systems. Contents of the mine are inherently protected from external electromagnetic-pulse (EMP) attacks.

4. The Lefdal Mine is massive. The green indicates the corridors on the various levels; each can be filled with containers for the data center.

iNNOVO Cloud, a German cloud provider, is one of the first international customers to move into LMD.