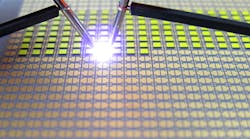

By optimizing the production of light-emitting diode (LED) components and light modules, a collaborative effort will focus on developing new types of LEDs as well as reducing manufacturing costs. The “Integrated High-Volume Production along the LED Value-Added Chain for Large Wafers and Panels” (InteGreat) project, led by Osram Opto Semiconductors, will research different approaches to the entire production process of LEDs to help create new functionalities and increase flexibility.

Alongside five other industry and research partners, Osram will attempt to use and adapt established technologies and processes from the microelectronics industry to meet LED production requirements. Following the classic assembly-line structure, steps that were previously isolated will now be networked to help replace comprehensive routines. The goal is lower-cost, miniaturized LED modules with a higher level of integration.

Osram’s partners include Osram GmbH, Fraunhofer-Gesellschaft, LayTec AG, Würth Elektronik GmbH & Co. KG, and Mühlbauer GmbH & Co. KG. The InteGreat project was started in December 2014 with support from the Germany Ministry for Education and Research as part of the Photonic Process Chains initiative. It’s expected to conclude in November 2017.