What you will learn:

- Single-pair Ethernet explained.

- What are the benefits of single-pair Ethernet?

- Key applications for SPE.

Ethernet is everywhere. Most of us use it daily. It connects everything and we can’t help but put it to work. The original coax-based LAN conceived in 1973 has grown to the point of almost complete coverage of all computer networking. It’s in our offices, buildings, factories, and homes.

With the relatively recent version of the standard, single-pair Ethernet (SPE) seeks to wrap up full networking coverage by addressing the Internet of Things (IoT), and specifically the industrial Internet of Things (IIoT) and Industry 4.0 application space.

Ethernet Summary

Ethernet is a wired networking technology developed and standardized by the working groups of the Institute of Electrical and Electronics Engineers (IEEE), tagged with the designation of 802.3. The first coax-based version ran at 10 Mb/s on a shared bus. Later versions switched to unshielded twisted pair (UTP) that offered lower cost as well as speed and range advantages. Over the years, dozens of versions have been created with speeds exceeding 10 Gb/s.

In the early years of PCs, Ethernet competed with other LAN standards like ARCNET and IBM Token Ring. Neither scaled well and Ethernet went on to fulfilling almost every networking need.

Today, the typical Ethernet LAN uses UTP cable with four pairs that can reach to 100 meters and achieve speeds of 10 Gb/s. And there are many variants and enhancements. Some versions use fiber-optic cable in various configurations to reach speeds of 400 to 800 Gb/s. That pushes Ethernet into the metropolitan-area-network (MAN) and wide-area-network (WAN) spaces, where it has virtually killed off synchronous optical networking (SONET) and competes with optical transport networking (OTN) in some cases.

While there’s a version of Ethernet for almost every occasion, it’s overkill for some potential applications. Therefore, new variations are warranted. That is where SPE comes in.

A Brief Look at SPE

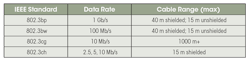

SPE is a version of Ethernet that uses only a single twisted pair cable, unshielded or shielded. It can be implemented in several different forms with data rates from 10 Mb/s to 1 Gb/s over a range of 15 meters to 1000 meters. The table shows what’s available.

An interesting option in SPE is a multidrop feature that can support up to 8 nodes on up to 25 meters of a UTP bus. An arbitration capability determines who transmits and when. SPE also is capable of carrying dc over the data cable to permit powering of the attached device without an additional supply. Standard Power over Data Line (PoDL) features with up to 50-W capability apply.

By the way, another single-pair Ethernet version exists. Known as automotive Ethernet (802.3bw), it runs at data rates up to100 Mb/s at up to 100 meters range. It also has full duplex capability using a sophisticated echo-canceling scheme. SPE is much simpler and targets industrial applications directly.

The Benefits of SPE

The key benefit of SPE is its simplicity, which helps reduce system complexity and leads to lower costs. Its wide range of data speed and range options allow it to fit almost all modern industrial applications. SPE cable is smaller, lighter, and has a smaller bend radius, meaning more sensors and cabling can be contained in a smaller space.

Weight and space reductions for cabling can be more than 50% in many cases. Reductions are so great that SPE is being adopted for commercial aerospace use in passenger planes. A standard called ARINC 854 Cabin Equipment Network Bus will specify SPE for up to 15 meters. Reducing cabling weight can produce enormous fuel savings in a large fleet.

One of the main goals of SPE is to eventually replace the larger number of fieldbuses used in industry. These buses connect directly to the sensors, actuators, and other devices that eventually will interface with the larger-facility Ethernet network.

Gateways are now used to make the transition from fieldbus to Ethernet. By implementing Ethernet down to the sensor level, no gateways are required and the whole network can use the favored TCP/IP protocols common with most Ethernet networks. A total Ethernet solution gives future factories and industrial facilities sensor-to-cloud coverage in a simpler format.

The PoDL capability is a real benefit, as it eliminates the need for batteries and maintenance that would otherwise be required for wireless sensors or devices. The result is improved overall reliability.

One More Thing

A missing part of the SPE movement concerns the connector or connector types. Standard Ethernet uses the familiar RJ-45 8 pin connector. Not SPE. Instead, there are multiple options on SPE cables.

All SPE connectors should comply to IEC standards 63171-2 (IP20), 63171-5 (IP67), and the newer 63171-7. M8 and M12 connectors along with others are carried by multiple vendors. Another option is the Mini-ETH connector for aerospace applications. No one standard has been proposed or adopted at this point, but variations to fit almost any situation are available.

SPE isn’t yet widely adopted, but it’s on the way. A sure choice for replacing fieldbuses and networks in any industrial setting.