FRAMs Fit Wearable Electronics Like a Glove

Ferroelectric-RAM (FRAM) memory is widely used in industrial control systems, industrial automation, mission-critical space applications, high-reliability military, and various automotive applications. The characteristics of FRAM that suit it for these applications also make FRAM a viable technology for wearable applications because of additional inherent attributes—low power and high endurance (Fig. 1).

A major consideration for electronic wearable designs revolves around reducing total power consumption while increasing reliability. Designers must add functionality while simultaneously shrinking the system’s power budget to achieve longer battery life. At the same time, though, embedded software is becoming larger and more complex, requiring more memory and thus further stressing the power budget.

Most of today's MCUs come equipped with two common types of memories: flash and SRAM. Flash is relatively slow and supports a limited number of write cycles. However, it’s non-volatile and therefore is used to hold slow-changing data, such as application code. By comparison, SRAM is fast and has unlimited write cycle endurance. Its volatile nature means it can only hold temporary data.

Choosing an MCU can become complex when trying to accurately determine how little flash and SRAM will be required for an application. As system complexity increases and designers need to introduce external memory, often the first option that comes to mind is to add more flash or an EEPROM and, in certain rare instances, external SRAM.

Wearable-Design Considerations

Energy consumption, form factor, high endurance, and cost are key design parameters:

• High demand for data assimilation drives demand for memories.

• Memories increasingly impact component selection and bill of materials (BOM).

• Saving battery life and reducing recharge times are now critical differentiating parameters in the market.

This file type includes high resolution graphics and schematics when applicable.

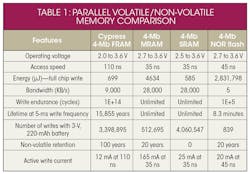

Typically, as a design becomes more complex through high code complexity and execution of multiple mathematical functions, designers may look at augmenting on-chip resources with an external memory. A low-power external parallel-interface memory would be the first logical option, typically a SRAM-type memory with extremely low active currents and, ideally, zero standby current (Table 1).

A parallel-interface FRAM could also be a candidate for this application. FRAM has densities up to 4 Mb and offers high-speed performance (90-ns access time) with very low active write and read currents. Since FRAMs are inherently non-volatile, they can be power-gated (off) when not in use or when the MCU goes into sleep mode.

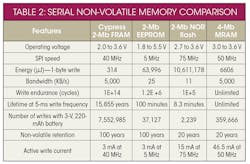

A similar problem arises for data storage, typically implemented in a serial flash (Table 2). Flash is the prevalent storage memory, mainly attributed to the low cost per megabit and larger densities available. However, flash has a major drawback in terms of energy consumption when writing—it drains batteries faster. Many developers try to partition flash and use an EEPROM that consumes less energy (i.e., write infrequently to flash and use EEPROM as a front-end for heavy writes). EEPROM standby and active modes consume lower currents than flash.

Another approach for such scenarios is an external serial interface FRAM with addressing capabilities, high speeds (40-MHz SPI), low active energy consumption (typically less than 100 µA/MHz) and densities up to 4 Mb. There are two principal advantages of serial FRAMs over MRAM, EEPROM, and flash-based memories (Fig. 2). First, when writing to FRAM, power consumption is multiple orders of magnitude better than other non-volatile memories. Second, its write endurance is near infinite. Simplifying the decision is the fact that FRAMs are usually available in packages similar to those of EEPROMs and flash.

Write Endurance Comparisons

Wearable electronic devices try to conserve energy to maximize battery life. Such applications rely on small bursts of energy that provide power in short time intervals. As a result, the MCU is usually very tight in terms of how many lines of code can be executed before power is lost.

Flash-based applications pay a premium in power, not only because of higher average power while accessing the flash, but also because of higher peak power during flash write events. This peak power is mainly due to the usage of a charge pump, which causes values to climb up to 7 mA, making non-volatile writes virtually taboo in the wearable electronics world.

FRAM has no charge pump; therefore, it doesn’t have high-current writes (Fig. 3). The average power when writing to FRAM is the same as when reading from, or executing out of, FRAM. There’s no penalty for non-volatile writes, making FRAM a truly flexible option for energy-saving applications.

Combine RAM and ROM in a Single Memory

Design engineers working on embedded systems usually select memories based on what they intended to store in it. Typical executable code is stored in nonvolatile memory, while data is stored in volatile memory (except for archival purposes). Most embedded systems, however, still maintain the traditional mix of memory technologies with applications.

Applications for memory technologies generally split between executable code and data tasks. ROM-based technologies, including mask ROM, OTP-EPROM, and NOR flash, are non-volatile. Thus, they’re oriented toward code storage applications.

Other derivatives of ROM technology, including NAND flash and EEPROM, can serve as a non-volatile data memory. These come at a compromise, since they perform both code and data storage with low performance relative to alternatives. Flash’s main virtue for data is its low cost, rather than ease of use or performance for data storage.

RAM-based technologies such as SRAM serve as data memory and as working space for code execution when flash is too slow. RAM provides an excellent blend of code and data functionality, but ordinary RAM offers only temporary storage.

This file type includes high resolution graphics and schematics when applicable.

Space-constrained applications require maximum functionality in a few devices. Even in applications with adequate board space, the design engineer may be unwilling to use three different memory types in the system. Ideally, a single memory technology could serve for code and data. Since it must be non-volatile, ordinary RAM is omitted from consideration. This leaves the ROM family of technologies, which offer poor performance as data storage media, undesirable battery-backed SRAM, or FRAM.

FRAM can lower system cost, increase system efficiency and reduce complexity while being significantly lower power than flash, EEPROM, SRAM, and other comparable technologies. If your existing flash/EEPROM-based application has energy, write speed, endurance, or power-fail backup constraints, it may be time to make the switch to FRAM.

References:

FRAM SPI Read and Write, Data Protection during Power Cycles

About the Author

Harsha Venkatesh

Product Marketing Manager

Harsha Venkatesh, product marketing manager for the Non Volatile Memory group at Cypress Semiconductor, previously worked as regional marketing manager for the company’s Munich, Germany location. He holds an MBA in marketing and a bachelor's in electronics engineering.

Shivendra Singh

Applications Engineer Principal

Shivendra Singh is an Applications Er. Sr. Principal at Cypress Semiconductor. He has more than 13 years of experience with various volatile and nonvolatile memory products, technologies, and system solutions. His current responsibilities include, but are not limited to, creating new product definitions and specifications, product failure analysis, developing validation platforms, demos and development kits, design models, and customer trainings.

Shivendra has published several technical articles on various topics including RAID, RTC, Wearable, and Automotive EDR in leading technical journals as well as authored many technical documents that include application notes on design, whitepapers, and knowledge base articles (available on Cypress' website).