Industrial applications for microcontrollers are broad and deep. They include automation and metering solutions, motor control, human-machine interfaces (HMIs), sensors, and programmable logic control. Increasingly, designers are adding MCUs into previously “unintelligent” nodes, and the spread of the industrial IoT will only speed that process. At the same time, industrial applications demand lower power consumption and wiser use of energy.

In response, manufacturers are introducing microcontrollers for the industrial and related markets that offer high performance and great flexibility, but are frugal consumers of power.

Industrial MCU Requirements

The industrial environment can be brutal for electronic equipment, replete with high currents and voltages, electrical noise, and spikes caused by motors, compressors, welding equipment, and other heavy-duty machinery, electromagnetic interference (EMI), static discharge, and so on.

With low-voltage operation and process geometries of 130 nm or less, the microcontroller simply isn’t equipped to handle these hazards by itself—that’s the job of external protection circuits, careful printed-circuit-board (PCB) layout, attention to power and ground routing, etc. Nonetheless, an industrial MCU is expected to meet many requirements of industrial applications if it aspires to succeed in this market. Let's review some of these key requirements.

Low Power Consumption

As modern process-control systems become increasingly complex, so does the requirement for embedded processing within individual remote sensor units. Whether it’s to process data locally or support the growing number of digital communication protocols, numerous industrial designs now include an MCU within the sensor node to enable additional features. MCU-powered nodes include motor-condition monitors, remote measurement of liquids and gases, and valve control.

Many industrial sensor nodes are far from a power source, where increased consumption translates directly into voltage drops down the line. Others derive their power from a current loop. Either way, low MCU power consumption is a must.

Many other industrial applications are battery-powered; examples include building automation equipment, fire and smoke detectors, motion detectors, electronic locks, and thermostats. A host of applications also pervade the medical and health fields, such as blood-glucose meters, heart-rate monitors, pulse oximeters, personal fitness trackers, and more.

Battery technology has not kept pace with the demand for more features in smaller and lighter packages, which increases the need to minimize power consumption. A microcontroller must consume minimal power during normal operation, and be able to transition to a low-power sleep mode and wake up in response to a specified condition (e.g., an internal timer or an external interrupt).

Data-Retention Capability

One thing about running on battery power: There will come a time when that power fails unexpectedly, most often because the battery is exhausted. A smartphone cutting out mid-conversation may be annoying, but losing a series of measurements in the middle of a medical or process-control application can be catastrophic. In non-battery industrial applications, a sudden shutdown might occur as a result of a power failure or overload condition.

For such applications, it's important that the microcontroller has the ability to detect the imminent loss of power and save key data. It would be even better if the device could retain the state of the CPU—the program counter, registers, clock state, GPIO status, etc.—so that it can resume where it left off without needing a cold restart.

Multiple Communication Capabilities

When it comes to communications, industrial applications run the gamut. In wired communications there's everything from legacy 4- to 20-mA current loops and RC-232 to Ethernet, USB, LVDS, CAN, and more. As the IoT picks up speed, multiple wireless protocols are entering the mix, including Bluetooth, Wi-Fi, Zigbee, and Thread, plus proprietary protocols. To put it mildly, it's unlikely that the industry will settle on a standard protocol anytime soon (or ever), so microcontrollers should be able to accommodate a range of communication options.

Security

The latest version of the Internet Protocol, IPv6, has a 128-bit address field, giving it a theoretical maximum of 3.4 × 1038 addresses. That's more addresses than there are grains of sand in the world! With so many devices potentially open to the outside world, security looms large as an issue. Many existing solutions are based on open-source software such as OpenSSL, and the results leave much to be desired.

A few horror stories have already occurred. In 2015, for example, researchers using a laptop and mobile phone hacked into a Jeep Cherokee through its wireless internet connection, and even managed to disable the brakes. That flaw has been fixed, but one of the things that keeps industrial IoT experts up at night is the prospect of a security breach in a massively networked application such as an automated factory, oil refinery, or even the smart grid. Remember Stuxnet?

A key requirement of a state-of-the-art industrial microcontroller, therefore, is robust hardware and software security features such as AES encryption.

A Scalable Set of Core Options

A product that tries to satisfy everybody ends up satisfying nobody.

Some industrial applications have low power consumption as a high priority; examples would be a wireless monitoring system to log temperatures in a cold-chain logistics system, or a smart medical patch that gathers physiological data. These systems spend most of their time in the sleep state and wake up periodically to perform a few relatively simple tasks.

Other applications are particularly cost-sensitive. Still others put the emphasis on performance, while keeping an eye on power consumption.

A large-scale industrial project will have a blend of MCUs with different combinations of performance and power consumption. To simplify development and speed time to market, it should be easy to port application code across cores as needs change or feature creep sets in.

A Flexible Peripheral Set

Given the vast scope of industrial control, sensing, and measurement applications, any industrial MCU family worthy of its name must offer an extensive array of peripherals. Some of the “must-haves” include:

• Medium resolution (10-, 12-, 14-bit ) analog-to-digital converters (ADCs) operating up to 1 Msample/s.

• High-resolution (24-bit) ADCs for lower-speed high-precision applications

• Digital-to-analog converters (DACs)

• Multiple choices for serial communication, especially I2C, SPI, and UART, but also USB

• Security features: IP protection/secure flash zones, Advanced Encryption Standard (AES) hardware accelerator

• Integrated LDO and dc-dc converters

• Specialized peripherals for common tasks, e.g. capacitive touch switch module, LCD driver, transimpedance amplifier, etc.

Powerful Development Tools

It'll come as no surprise to working engineers that as projects become more complex, development schedules seem to stay the same or even shrink. To keep up, any industrial microcontroller family must come with comprehensive support that includes software, tools, and development kits.

The software-development ecosystem should incorporate a GUI IDE, an RTOS, debugger, code examples, code-generation tools, peripheral configuration wizards, driver libraries, and APIs. There should be support through the design process, preferably with online access to factory experts and a lively community of online users exchanging tips and advice.

The MSP43x Family of Low-Power Industrial MCUs

We wouldn't spend considerable time discussing the requirements of an industrial microcontroller family without suggesting a solution. Several manufacturers have developed products to meet this growing market, such as Texas Instruments with its MSP43x family, which offers a powerful combination of high-performance and low power consumption.

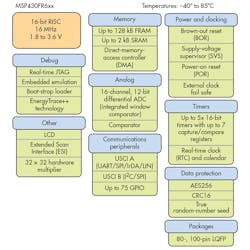

Over 500 devices populate the MSP43x family, including both MSP430 ultra-low-power (ULP) versions based on a 16-bit RISC core, and the MSP432 devices offering a combination of low power plus performance. These devices feature a 32-bit ARM Cortex-M4F core with a floating point unit and up to 256 kB of flash memory.

The MSP430FRxx set of 100 devices features ferroelectric random access memory (FRAM) for unique performance advantages. FRAM, also known as FeRAM or F-RAM, combines features of flash and SRAM technologies (Fig. 3). It is non-volatile like flash, but offers fast and low-power writes, a write endurance of 1015 cycles, improved code and data security compared to flash or EEPROM, and high resistance to radiation and electromagnetic fields.

The MSP43x family supports many industrial and other low-power applications, including grid infrastructure; process control; test and measurement; building and home automation; medical health and fitness; personal electronics; and many others.

Let's take a look at a couple of industrial application examples for these parts.

Sample ULP Application: Nine-Axis Sensor Fusion Using the MSP430F5528

In sensing and measurement applications, multiple sensors are increasingly being “fused” together into systems that employ both hardware and software to intelligently combine data from several devices. The fused data corrects for individual sensor deficiencies and improves performance when determining position or orientation.

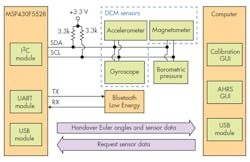

Figure 4 shows the block diagram of an attitude and heading reference system (AHRS) that uses the ultra-low-power MSP430F5528 MCU, a magnetometer, a gyroscope, and an accelerometer on all three axes. The MSP430F5528, optimized for extended battery life in portable measurement applications, contains a16-bit RISC core, a hardware multiplier, a 12-bit ADC, and several serial modules including USB.

The software employs the direction-cosine-matrix (DCM) algorithm, which takes the calibrated sensor readings, calculates the device orientation, and outputs the result as a set of pitch, roll, and yaw values, called Euler angles.

If necessary, the MSP430F5xx can communicate with the motion sensors via the I2C serial protocol. This can deliver benefits across the entire system, since the main microcontroller is freed from continuously processing the sensor data. It can either remain in sleep mode to reduce power consumption, or direct more resources to other tasks to improve performance.

More information about this application can be found here.

Sample High-Performance Application: BPSK Modem Using the MSP432P401R

For a high-performance industrial application, let's examine a 125-kb/s BPSK modem implemented using the MSP432 32-bit MCU.

Binary phase-shift keying (BPSK) is a digital modulation scheme that transmits data by varying the phase of a carrier reference signal. A typical application would be an optical communication system, which uses a BPSK modem to provide an additional channel for a low-data-rate signaling link.

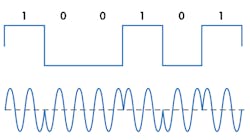

BPSK utilizes two distinct signals to represent binary digital data in two different phases for modulation; a carrier of one phase represents bit 0, while a 180-degree-displaced phase represents bit 1. Figure 5 illustrates the BPSK waveform.

The MSP432P401R MCU forms the basis of the design. In addition to the 32-bit ARM Cortex-M4 core, this device features a 14-bit, 1-Msample/s ADC and the CMSIS digital-signal-processing (DSP) library, allowing it to efficiently handle complex DSP functions.

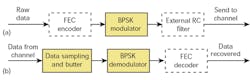

Figure 6 shows the transmitter (modulator) and receiver (demodulator) blocks. The implementation includes BPSK modulation and demodulation, forward error correction (FEC) to improve BER, and digital signal conditioning. The BPSK demodulator incorporates an optional finite-impulse-response (FIR) low-pass filter to improve the signal-to-noise ratio (SNR) before demodulation.

Specifications of the BPSK modulator are:

• 125-kHz carrier frequency

• A bit rate of up to 125 kb/s

• A complete packet or frame of up to 600 bytes

• x4 oversampling of the 125-kHz carrier (i.e., a sample rate of 500 ksamples/s)

More information is available in an application report that outlines the design. It describes a complete modem that’s implemented in software with minimal external components, giving an inexpensive, low-power, and compact solution.

Conclusion

Microcontrollers for industrial use must have a combination of high performance, low power consumption, a flexible feature set, and a powerful software-development ecosystem. TI's MSP43x family of parts offers designers a choice of over 500 devices based on a single platform that covers the whole range of industrial sensing and measurement applications.

Looking for parts? Go to SourceESB.