11 Myths About ALS/Proximity Sensors

Download this article in PDF format.

Most design engineers of consumer and industrial products always look for various ways to achieve their desired goals in applications ranging from wearables to handheld devices to industrial appliances. One common thread between these applications is that they need some type of sensor(s) and actuators or decision engines to determine the actions to be taken.

Ambient light and proximity sensors (ALS/Prox sensors) are used in many of these Internet of Things (IoT) devices, home and factory automation, and handheld and wearable devices to reduce power consumption, determine screen brightness, turn on/off the screen, detect the level of the liquid in a tank, measure the proximity of the piston in a chamber, and so on.

What follows are the conventional myths that surround ALS/Prox sensor usage in various scenarios and applications—and reasons why they can all be debunked.

1. IR-based proximity sensing cannot be done under direct sunlight.

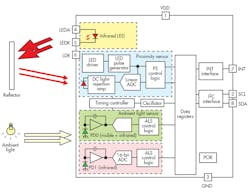

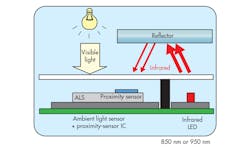

Proximity sensors can be used outdoors under direct sunlight to determine proximation. The ALS/Prox sensor detects, and subsequently cancels out, the ambient IR. It depends on the IR emitter intensity and pulse to detect the proximity. Figure 1 shows a typical ALS/Prox sensor block diagram.

1. This block diagram represents a typical ALS/Prox sensor.

2. Different light types affect the performance of an ALS.

An ambient light sensor provides consistent light reading irrespective of the different light sources.

3. An integrated IR-LED proximity sensor experiences more crosstalk than separate sensors.

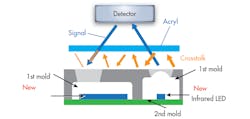

It’s been shown that integrated IR-LED proximity sensors don’t have any more crosstalk than an individual sensor due to its double-molding type of package (Fig. 2).

2. Double-molding packaging helps minimize crosstalk in ALS+Prox sensors.

4. The ALS/Prox sensor doesn’t work properly behind dark-tinted glass.

ALS/Prox sensors have enough sensitivity whereby they will work effectively behind dark-tinted glass. The software controller’s high-sensitivity mode allows light to be measured even behind the dark glass.

5. An ALS/Prox sensor requires external analog-to-digital converters (ADCs) to provide digital information.

These sensors have an internal ADC block, therefore they don’t require the end user to design an external block. A microcontroller can directly read the ALS and proximity data using an I2C bus.

6. IR-based proximity sensors can detect objects at distances over several yards.

These sensors can only detect distance in the range of 1 to 100 mm. Hence, they’re used to detect proximity in small areas as well as in handheld and wearable devices. This capability also is useful in certain devices targeted for the industrial space.

7. Indoor artificial lights with 50/60-Hz power affect ALS performance.

Most ALS/Prox sensors will have built-in 50/60-Hz light noise filtering to provide consistent ALS output, even in indoor light conditions.

8. An IR-based proximity sensor consumes very high power (hundreds of mA).

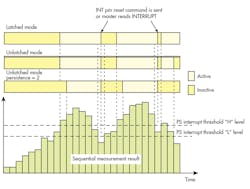

The ALS/Prox sensor has the ability to control the IR-LED ON time to minimize power consumption. As a result, the IR-LED will be ON only during measurement time, which drastically reduces total power consumption (Fig. 3).

3. Idle time between measurements reduces power consumption.

9. IR-based proximity sensor can’t work in dark environments.

Not true. Such sensors can work in the dark or inside the enclosure. Since the IR-LED is built into the sensor module, there’s no need for an external light source to measure the distance from the sensor to the object (Fig. 4).

4. An external light source isn’t needed for a proximity sensor to work in the dark. It only requires its IR source.

10. Assembly requires special handling.

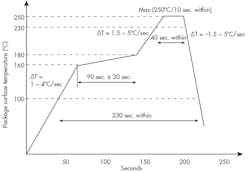

IR-based proximity sensors are robust devices; there’s no need for any special assembly techniques (Fig. 5). Sensors can be used like any other surface-mount component.

5. The plot shows the soldering profile of ALS/Prox sensors.

11. Proximity sensors discriminate in terms of color.

ALS/Prox does NOT discriminate against different colors; the sensor still emits same amount of light. The reflection of the light heavily depends on the color and type of reflective material.