The electronic content in modern cars has increased tremendously thanks to the demand for in-car entertainment (“infotainment”) systems and features, such as docking for smartphones, USB ports, and satellite radios. The latest cars also are expected to boast GPS navigation systems with mapping capabilities, interior and exterior LED lighting, and other sophisticated features.

Government requirements for safety features are adding impetus to the proliferation of in-vehicle electronics as well. For example, backup cameras will be mandatory in new cars in 2018. Meanwhile, state laws requiring hands-free calling while driving mean that cell-phone interfaces will become standard features.

This file type includes high resolution graphics and schematics when applicable.

USB Applications

USB 3.0 ports are now common in cars. In addition to overcurrent and overvoltage protection, sensitive electronics that use high-speed USB (and HDMI and other high-speed interfaces) require protection against electrostatic discharge (ESD). Three different types of circuit protection devices can help stave off these potentially damaging events.

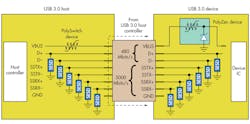

A PolySwitch PPTC (polymeric positive temperature coefficient) device can be used for resettable protection in USB applications (Fig. 1, left). Placing the PPTC device on the VBUS port of a USB power source limits the current in the event of a short circuit. It also helps prevent overcurrent damage caused by a sudden short circuit downstream and helps achieve UL60950 compliance.

For overvoltage protection in USB 3.0 applications, the PolyZen device uses a hybrid approach (Fig. 1, right). It integrates a Zener diode and a PPTC device, which are thermally bonded. PolyZen parts can be used inside USB ports to prevent an upstream regulator failure from putting out a high voltage that can damage components plugged into the USB port.

Finally, for ESD protection, circuit protection products such as silicon ESD (SESD) devices can be placed on the USB data lines. These ultra-compact (0402- and 0201- sized) devices have the low capacitance that high-speed applications like USB 3.0 need.

12-V dc Systems

Power that feeds video monitors on the backs of seats, powered antennas, and other accessories needs short-circuit protection. It is very easy to short out power to the vehicle ground when installing equipment. Docking ports also have power outputs that need short-circuit protection.

Traditionally, fuses have protected power inputs and outputs in 12-V dc systems. PolySwitch PPTCs offer a cost-effective, resettable alternative to fuses by helping to protect driver outputs from inadvertent short circuits or other load anomalies.

Video Outputs

Video outputs in car infotainment and other systems also need ESD protection. HDMI and other high-frequency outputs need low-capacitance ESD protection. When designing HDMI systems, using ESD protection devices that can operate at 3.4 GHz without affecting the signal integrity minimizes design headaches, increases system margin, and facilitates next-generation designs by eliminating the need for a full redesign of the ESD protection scheme down the road.

RF Outputs

RF outputs such as Bluetooth, GPS, and satellite radio antennas may need ESD protection as well. Protecting exposed communication interfaces from ESD and other voltage surges induced through the antenna and the instrument’s wireless (RF) interface is a critical design issue.

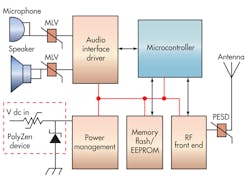

A PolyZen device can help protect the power input to a Bluetooth module (Fig. 2). Also, Polymer ESD (PESD) devices can be used to help protect the antenna against ESD surges. PESD devices, like SESD devices, have the low capacitance needed for high-speed data transmission lines and RF data lines. They are available in compact surface-mount device (SMD) packages and can withstand numerous ESD strikes.

LED Lighting

Interior and exterior LEDs are increasingly being used in automotive designs. Although efficient and long lasting, LEDs are vulnerable to heat, ESD, and short-circuit anomalies that can lead to product failure and potentially safety issues. Automotive manufacturers, therefore, use circuit protection for these lighting systems.

Most of the electrical energy supplied to an LED is changed into heat, not light. If not dealt with, the heat will reduce the LED’s life and alter the quality of the light that is produced. A PolySwitch PPTC device can be used in series with the LED to provide overcurrent protection.

Additionally, this resettable device can provide overtemperature protection if it is thermally bonded to the metal core circuit board or LED heatsink. Problems can also occur if the LED driver’s outputs are damaged or destroyed by being inadvertently shorted. If the driver circuit does not require input protection, PolySwitch PPTC devices can be used to help protect driver outputs.

ESD protection is also necessary if the LED does not have built-in protection. In this case, a PESD protection device placed in parallel with the LED can help protect against possible damage.

Many LED drivers are susceptible to destruction by improper dc voltage levels and polarity. Placing a PolyZen device on the input of the LED driver helps protect the driver from inadvertent exposure to overvoltage and reverse polarity events.

Conclusion

With the increase in car electronics designed for consumer entertainment and peace of mind comes the increasing potential for electronic failures, which, ironically, can result in the opposite effect: warranty repairs, safety issues, and overall customer dissatisfaction. That’s why today’s circuit protection devices go well beyond traditional fuses to help ensure reliability, performance, and safety in automotive electronics.

Barry Brents is a field application engineering manager with TE Circuit Protection, a business unit of TE Connectivity. A member of IEEE and former U.S. Navy nuclear submarine officer, he has been involved in the power and communications industries since 1989. He received his BSEE from Texas Tech University.

About the Author

Barry Brents

Field Application Engineering Manager

Barry Brents is a field application engineering manager with TE Circuit Protection, a business unit of TE Connectivity. A member of IEEE and a former U.S. Navy nuclear submarine officer, he has been involved in the power and communications industries since 1989. He received his BSEE from Texas Tech University. He can be reached at [email protected].