IoT and other sensor-based applications have a constraint: how to connect the switches and other motion-based sensors to a local Wi-Fi network. Running even a small switch-closure wire between a transducer source point and a local wireless node is often a physical nuisance, especially if that point is on a moving object such as a door or a bottle.

To address this problem, a team at the University of Washington (Seattle) claims to be the first to devise a way to print 3D (additive manufacturing) objects that function as sensors using plastic with embedded conductive threads, and then connect these wirelessly to the local 2.4-GHz Wi-Fi node. The technique uses RF backscatter so that the Wi-Fi system sees the change in physical appearance or location of the sensed object (they call them “widgets”). The result is a low-cost, wireless, zero-power transducer/Wi-Fi link (Fig. 1).

1. The zero-power switch interface uses the changes in Wi-Fi RF backscatter, which occurs with small-scale motion of plastic, 3D-printed objects having embedded, conductive filaments. (Source: University of Washington)

Their detailed yet highly readable paper, “3D Printing Wireless Connected Objects,” explains the concept. It shows the many test widgets they built, and discusses the range of tests they conducted.

The team demonstrated that their approach allows detection of simple actions, such as a mechanical on/off switch being activated. Further, they could also use the magnetic properties of the ferromagnetic plastic material to encode up to 12 bits in a short stream in the widget, which could be sensed and decoded using a smartphone-based maglink receiver. Data rates were on the order of 10 bits/s (slow, but sufficient for the application) over distances in the tens of centimeters range (again, adequate for many IoT applications).

Banking on Backscatter

Key to the detection technique is use of backscatter, the pattern that a receiver sees due to conductive objects in an RF field. When an object moves or changes shape, the backscatter signal is affected, and this change can be detected and demodulated. (Backscatter is somewhat like radar, which relies on an intentional transmit pulse and received echo.) To make the team’s technique work well, each 3D-printed widget incorporates a reflecting antenna (dipole or bowtie) to enhance the distinctions in the backscatter signal among its positions.

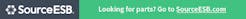

2. This simple on/off switch incorporates a bowtie antenna to enhance RF reflectivity, thus affecting the backscatter signal, shown in pressed (a) and unpressed (b) states. (Source: University of Washington)

For example, the team built several very different versions of a basic on/off switch. In one design, the switch replicates the action of a pushbutton using a cantilever separating spring element (Fig. 2). They used a planar spring built as a 1-mm-thick spiral structure, with the outer edges of the spiral fixed to a rectangular case, and increased the contact area of the switch by 100X to improve the difference in backscatter radar cross section. The integral bowtie antenna has a relatively wide beam width and greater bandwidth than a dipole, thus making it more resilient to fabrication error.

3. The concept has been expanded to a flowmeter transducer with a simple gear, which causes backscatter pulsing as the fluid flow rotates the gear. (Source: University of Washington)

The team’s concept is not limited to simple on/off switches. They also used a printed gear-tooth assembly to implement a flowmeter (Fig. 3), which they then attached to a standard liquid-detergent bottle via a printed fitting. As the detergent was poured out, the gear rotated and thus signaled, again via on-off transitions, the volume of liquid flow and use.

The complementary challenge to designing and fabricating useful 3D-printed objects, which affect backscatter due to position, is the reception, demodulation, and signal processing of these backscatter signals. Figure 4 shows the backscatter signal as a narrowband transmission embedded on top of the ambient Wi-Fi signals.

4. Capturing, demodulating, and decoding the backscatter is a signal-processing challenge, given the generally low SNR and other impediments, but the idea has been successfully demonstrated over limited distances, and despite motion of the reflecting object itself. (Source: University of Washington)

Adding to the difficulties are the ever-present noise, adjacent signals, marginal signal-to-noise ratio (SNR), and even movement of the widget itself with respect to the Wi-Fi system (the object being sensed could be part of a mobile product, such as that detergent bottle). To overcome the basic reception and decoding issues, they used a variety of data-encoding and signal-processing techniques that are discussed in the paper, along with graphs of test results along various perspectives.

Whether is this a viable approach in the real world is obviously an open issue, but it’s an interesting demonstration, yet again, of how highly disparate technologies can combine to offer a new approach to an old problem. Here, Wi-Fi, backscatter, signal processing, and complex 3D-printed conductive plastic objects offer an approach to providing wireless, zero-power connectivity between a transducer and associated node.