LDO Regulators: An Unexpected Option for Industrial/IoT Applications

Download this article in .PDF format

The power supply for new products is often taken for granted. However, judging from recent experience, it’s clear that the power supply for new industrial equipment or Internet of Things (IoT) products is a major factor in product success and reliability.

One unexpected realization gleaned from the latest designs is that the often-neglected low-dropout (LDO) linear regulator can go a long way to help designers meet the stringent needs of such products. Whether your new power-supply design operates from the ac line or batteries, the LDO may just be the solution you are seeking.

LDO Fundamentals

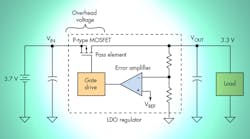

An LDO is a linear feedback voltage regulator that has a low dropout or overhead voltage. The overhead voltage represents the difference between the input and output voltages and the lowest value that can occur before the closed-loop regulation stops working.

Linear regulators typically place a transistor in series with the high side of the power supply between the input and output. The transistor’s conduction is controlled such that the output voltage stays constant despite input line variations or load changes. The goal is to minimize the transistor voltage drop to keep power consumption as low as possible. Low voltage drop means that a smaller, less expensive transistor can be used and there may be no need for a heat sink.

Most linear regulators use an NPN transistor or N-type MOSFET for the series control element. The circuit is basically an emitter (or source) follower. The output voltage is monitored and compared to a fixed stable reference to develop a feedback-control error signal. If the output voltage changes, the error signal is used to vary the base current or gate voltage to control the conduction of the series pass element. This will correct for any output variations.

This method of regulation is very effective but has some downsides. First, the regulation ceases to function if the overhead voltage drops below some minimum value—typically around 2 V for an NPN transistor or N-type MOSFET. Second, one must deal with power dissipation in the transistor created by overhead voltage and load current. Heat and wasted power are undesired consequences.

An LDO solves this problem by using a PNP transistor or P-type MOSFET as the series pass device (see figure). The circuit is now a current source or amplifier rather than an emitter (source) follower. The P-type devices can operate near saturation with minimal voltage drop. A typical LDO overhead voltage is less than 100 or 200 mV, and can be as low as tens of millivolts for low-power cases. The low overhead generates less heat and power loss while maintaining good line and load regulation. And remember, good regulators also significantly attenuate ripple.

When considering an LDO for your next design, it’s best to review the main design criteria for industrial and IoT power supplies, which include:Design Considerations

• High efficiency: In other words, the ratio of output power to input power expressed as a percentage. Obviously you want this to be as high as possible. Switching regulators offer great efficiency, but are noisy and create EMI that’s unwanted in an industrial environment or at home.

• Low heat generation: High efficiency leads to less heat dissipation. Parts can be smaller and less expensive.

• Superior regulation: Since many if not most industrial and IoT applications feature sensors, a clean, highly stable dc supply is mandatory. Sensors must detect and resolve very small changes in converting physical variations to measurable voltages. Even small supply variations can cause sensors to produce errors, resulting in erroneous measurements. A stable, noise- and ripple-free supply is essential.

• Low shutdown and quiescent current: Even when a regulator doesn’t supply an output, it consumes some power of its own. In a shutdown mode, where no output voltage or current is supplied, the regulator does draw some current itself. The same situation exists in an idle state with an output voltage but no load current—some small quiescent current is drawn. Though it’s usually small (microamperes), this current nonetheless decreases efficiency. Standby or idle currents really add up when multiple devices are involved.

• Clean, near pure, dc output with minimal noise and ripple: Industrial environments are already noisy, so no need to add to this problem. And normal power-supply ripple can introduce errors and incorrect operation. Good filtering and regulation are the solutions.

Design Examples

A modern utility meter for monitoring electric, gas or water usage exemplifies how to meet such design objectives. Low power consumption is imperative for modern meter design. Whether you’re measuring gas, water, electricity, or heat, you must limit the current draw to achieve long battery life and/or prevent inaccurate readings.

The design challenge is the dc supply for the microcontroller and sensors. With an electric meter, the ac line is present; therefore, power can be extracted and conditioned for the dc supply. Battery backup may also be required. Gas and water meters require a battery supply with a long life (up to 10 years).

A typical ac supply uses a series capacitor and resistor to drop the line voltage down to IC levels, eliminating the need for a transformer. A half-wave rectifier and shunt Zener provide an initial dc voltage that’s subsequently conditioned by an LDO regulator. Battery backup is often provided with an isolation diode. For gas and water meters, a long-life battery is used followed by an LDO regulator. Here, the low shutdown and quiescent currents of the LDO play an important part in extending battery life. In both the ac and battery supply cases, the LDO delivers clean stable power to the microcontroller and any sensors.

Another design example concerns the Internet of Things (IoT) products appearing with greater regularity in our homes and work places. As more appliances and systems integrate IoT electronics, suddenly we’re beginning to spend an incredible amount on standby power. The design question then becomes: “What can we do to make our thermostats, doorbells, security systems, and other IoT products more efficient while maintaining the same functionality and connectivity?” A simple linear regulator (LDO) is part of the answer.

Because most IoT products are sensor-based, they require a precise, stable, and ripple-free supply. Both ac and battery supplies are good candidates as this regulator for an LDO design. Their high power-supply rejection ratio (PSRR) makes them a superior ripple “filter.” The LDO is probably the best source of dc for sensors next to a battery. Its low idle and quiescent currents reduce standby-power consumption to a minimum.

In some IoT and industrial designs where efficiency is essential, a good power-supply combination should follow a dc-dc converter or switching regulator with an LDO. The switch-mode devices deliver the efficiency, while the LDO provides the cleanest most stable output. Keep this combination in mind as a way to have your cake and eat it too.

A Measurement Solution

One problem facing engineers who design appliances and other energy-consuming products is how to measure power consumption and related characteristics. In most cases, engineers have to cobble together test fixtures of voltage and current meters to do the job. One interesting alternative is Texas Instruments’ Energy Watchdog. It’s a reference design that engineers can apply to build this useful tester.

The Energy Watchdog design is a complete tool used to measure and display the energy consumption of an individual load, such as in a major home appliance. This reference design can speed engineers’ development time, as it comes complete with hardware and software design files. The ac product to be evaluated plugs into the Watchdog, and the Watchdog plugs into the ac line. An LCD shows the date and time, as well as key electrical factors. Available measurements include voltage (120-240 V), current (10 A max), frequency (50 or 60 Hz), active power (W), reactive power (var), apparent power (VA), power factor (cosθ), and energy consumption (kWh).