Semiconductor companies are keenly aware of the benefits silicon-carbide (SiC) devices bring to electric vehicles—it’s a market that continues to flourish thanks to the significant ramp up of power electronic solutions. On that front, automaker Venturi teamed up with Rohm to test and push forward new SiC technology solutions that increase the power efficiency of electric vehicles for Formula E.

Venturi opted for SiC material because of attractive properties such as higher voltage capability with lower power losses, which could ultimately lead to the use of smaller passive components. Compared to silicon (Si) material, SiC has 10 times higher electric-field breakdown capability, and offers higher thermal conductivity as well as higher temperature operation.

1. Rohm’s Nobohuri Hase, Senior Manager, Power Device Marketing, gives a presentation of the evolution of SiC power devices on EV/HEV.

At the SiC and electric-vehicle (EV) seminar hosted by Rohm, we learned that the Venturi Formula E team will be using Rohm’s Full SiC Modules for season four of Formula E. Nobuhiro Hase (Fig. 1), Senior Manager for Rohm’s power device marketing, explained the evolution of SiC power modules for Formula E from season 3 to season 4.

In season 3, Rohm used a hybrid power module containing a pair of SiC Schottky barrier diodes (SiC SBDs) and a pair of silicon IGBTs. British sports car maker McLaren developed the inverter in season 3 for the Venturi Formula E team. Adopting the SiC SBDs reduced the weight of the inverter by 2 kg and the volume by 30%. For season 4, Rohm and the Venturi Formula E team are planning to use a 1200-V, 600-A rated full SiC module (BSM600D12P3G001) that includes a pair of SiC SBDs and pair of SiC MOSFETs (Fig. 2).

2. SiC power modules continue to evolve in Formule E. (Courtesy of Rohm)

The inverter used in season 3 sat on top of the battery (Fig. 3). However, in season 4, the Venturi Formula E team will have more freedom to position the inverter. That’s because it will be smaller and, therefore, easier to place in a lower point of the car, giving the car more speed and efficiency.

3. Here, an inverter sits on top of the battery of a Venturi team car. (Courtesy of FIA Formula E)

According to Rohm, a full SiC module can reduce switching losses by 64% (at a chip temperature of 125°C) when compared with IGBT modules at the same rated current, considerably improving energy savings. To achieve larger currents, Rohm minimized inductance by 23% within the package by optimizing the internal placement of the SiC device, along with terminal configuration and pattern layout. Rohm also claimed to have decreased the thermal resistance between the cooling mechanism and the customer’s baseplate by 57%.

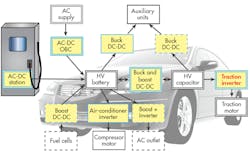

Formula E pushes the limits of power electronics technology to find the most efficient way to use a battery’s energy. It’s led to a number of many EV/HEV promising applications for SiC devices (Fig. 4).

4. A number of promising EV applications would likely take advantage of SiC devices. (Courtesy of Rohm)

According to IDTEchEX’s “Power Electronics for Electric Vehicles 2017-2025” report, the market will reach $300 billion in 2027. The report also says the market for traction inverters alone—which are crucial for traction motors—will escalate to $45 billion in 2025.

Electric vehicles will benefit from new SiC power solutions by having simpler cooling systems. Furthermore, they will extend the life of the EV’s battery, and recharging batteries will be much quicker with improved on-board chargers (OBCs) and dc-dc converters.

In the future, the EV market will benefit greatly from the power electronic solutions coming out of excellent test-bed platforms like the Formula-E. It comes as no surprise, then, that more chipmakers are working on earning automotive qualification according to the AEC-Q101 standard for wideband-gap devices aimed at in-vehicle power electronics. Expect to see a surge in wideband-gap technology solutions for electric vehicles, not only from SiC chipmakers, but from GaN chipmakers as well.