Simplify Automotive Powertrain Design with Distributed Power Supply

This file type includes high-resolution graphics and schematics when applicable.

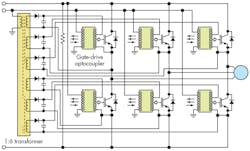

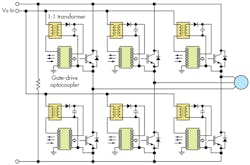

Conventionally, a centralized power supply is applied in an automotive powertrain through a multichannel transformer that converts 12-V dc power from the battery to supply six, isolated gate-drive circuits (Fig. 1).

Designers face many challenges in a centralized transformer model, including layout complexity and electromagnetic interference (EMI). There are also challenges associated with larger board space and higher printed-circuit-board (PCB) cost, as more layers are needed to route isolated signal/power lines.

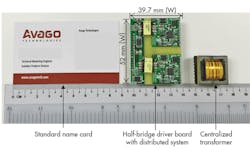

A distributed power supply can be easily built using a few discrete components and a small high-efficiency transformer placed next to the IC integrating an automotive-grade smart gate drive with integrated flyback controller (Fig. 2). This reduces the overall footprint and minimizes EMI and noise coupling between insulated-gate bipolar transistor (IGBT) channels.

Design Simplicity

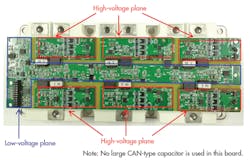

With a distributed-power-supply architecture, designers have more flexibility in planning the circuit layout; the low-voltage plane can be distinguished and isolated easily from the high-voltage plane. In addition, overall PCB routing becomes more manageable and straightforward.

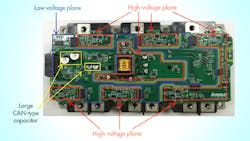

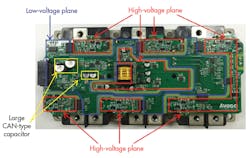

Figures 3 and 4, respectively, compare a six-channel IGBT gate-driver board based on a centralized power supply versus one based a distributed power supply. It’s obvious that a distributed-power-supply architecture offers a simplified PCB layout and more efficient routing. There are no PCB traces or power planes crossing between low- and high-voltage circuits, enhancing the signal integrity and avoiding unfavorable noise disturbance to the signal lines.

Robustness

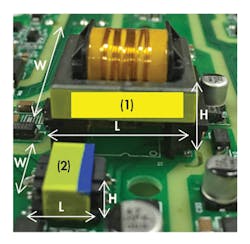

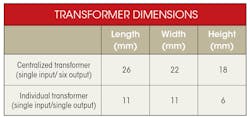

The transformer in a distributed power supply is typically 14 times smaller in volume versus a centralized transformer. Figure 5 shows an individual transformer placed next to a centralized transformer. The table shows actual dimensions of a centralized transformer and an individual transformer.

A low-profile single transformer for each driver also improves reliability and robustness, compared to heavier, higher-profile transformers that are more vulnerable to mechanical vibration. While the power-supply capacitors used in a centralized-power-supply architecture tend to be larger and in a radial CAN package with a high profile, designers choose a smaller SMD package capacitor for a distributed power supply. The voltage ratings required for these capacitors is at least 10 to 20 V lower than those required for a conventional centralized-power-supply circuit.

Cost Savings

On top of design simplicity and robustness, another benefit of choosing a distributed power supply is cost savings through the minimization of overall board size and PCB layers. A distributed system of drivers and a single transformer allows these components to be placed closer together, saving critical board space.

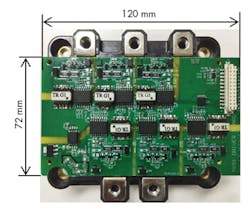

A distributed system also helps reduce the number of PCB layers because there’s no crossing of low-voltage traces/planes between the high-voltage traces/planes. This ensures that no extra layers are needed for passing the crossing signals. Figure 7 shows an example of a compact six-channel gate-driver board designed for the Fuji M651 IGB that uses only four layers of PCB.

Better EMI Performance

A large six-channel transformer in a centralized power system typically emits a lot more EMI noise than individual small transformers. In a distributed power supply, each smart gate-drive optocoupler drives an individual transformer with an integrated dc-dc controller to provide power to the secondary side for driving the IGBT arm.

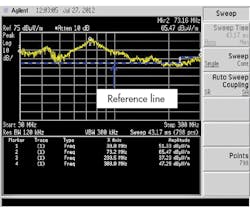

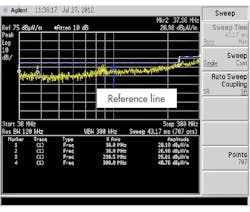

Measurements show significantly higher EMI noise from a centralized six-channel transformer (Fig. 8) as compared to small individual transformers (Fig. 9).

Conclusion

A distributed power supply further simplifies automotive multichannel IGBT gate-drive design versus that of a gate-drive board using a centralized power supply. Furthermore, it improves robustness, EMI performance, and module cost when compared to a conventional centralized-power-supply architecture.

References:

“Automotive R2Coupler Smart Gate Drive Optocoupler,” Broadcom Limited, 2016.

“AV02-4412EN Design of Isolated Flyback Converter for IGBT Gate Driver,” Application Note, Avago Technologies, December 2015

“IGBT Modules for EV, HEV,” Fuji Electric, 2016.

Looking for parts? Go to SourceESB.

About the Author

Roy Tan

Technical Consultant

Roy Tan joined Broadcom Limited (serving previously at Avago Technologies and Agilent Technologies) in 2000 and is a Technical Consultant for gate-drive optocouplers in automotive inverter applications. He holds a Bachelor’s in Electrical Engineering from the National University of Singapore.

Mei Zhen Choo

Application Engineer

Mei Zhen Choo joined Broadcom Limited (serving previously at Avago Technologies) as Technical Marketing Engineer in the Isolation Product Division. For the past seven years, she has been working with automotive customers on power-inverter design and has achieved various design wins with customers. She holds a Master’s in Electronics Engineering from Universiti Teknologi Malaysia and a Bachelor’s in Electrical and Electronics Engineering from Univerisiti Tun Hussien Onn Malaysia.