What you’ll learn:

- Design considerations for pulse density modulation (PDM).

- Design considerations for inter-IC sound (I2S).

- Pros and cons of two popular digital interfaces in MEMS microphones.

Small, portable microphones that can be used in embedded systems have been available for years, but the introduction of MEMS microphones has made their usage grow dramatically. The combination of increased demand and better technology has created a flurry of new voice-based applications in nearly every industry.

MEMS microphones, with their smaller footprint, low-power requirements, and greater immunity to EMI, also give designers flexible output options for improving performance. Analog is still an option for MEMS microphones, but pulse density modulation (PDM) and the inter-IC sound interface (I2S) are popular digital protocols that have become de facto standards for most audio applications.

Although PDM and I2S interfaces are both digital, how they transmit digital data is completely different. These differences have pros and cons that anyone using the standards need to understand to get the best approach for their application. A few of the most important items to consider when comparing these two protocols are:

- Audio quality

- Bill-of-materials (BOM) costs

- Space constraints

- Power consumption

- Environment of the application

What is Pulse Density Modulation?

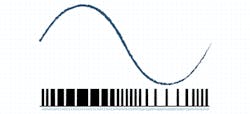

A pulse-density-modulated (PDM) signal represents an analog signal by changing a single bit high or low for a period of time depending on the analog signal’s voltage level. As the analog voltage signal increases, the percentage of the digital signal that’s high increases, too (Fig. 1).

Conversely, lower voltages are represented with fewer high bits. This creates a signal made up of digital components, but it’s still directly related to the analog signal. Yet, to represent an analog signal with digital bits, the pulses must have a much higher frequency than the original signal, generally higher than 3 MHz.

Although the PDM signal can be visually associated with the analog original, the PDM version is much better at ignoring electrical interference, as each bit of information is a distinct one or zero. This same feature lets PDM work through signal degradation with less noticeable decrease in quality.

However, it puts greater demands on the cables and electronics involved due to the increased effect of capacitance on high-frequency signals. Moreover, although they may look similar to their source signals, the PDM protocol requires additional processing by a digital signal processor or microcontroller to downsample, or decimate, the signal to a lower sample rate before it’s useful to other devices.

Since the general concept is so simple, PDM-based devices only require two signals and are generally less power-intensive, smaller, and less expensive. But the additional processing may make these benefits moot if more circuitry is needed.

What is Inter-IC Sound (I²S)?

The other popular digital audio protocol, I2S, has been around since the 1980s. Despite its similarity in style to I2C, a popular data-transfer protocol, I2S is completely unrelated to it. I2S is now widely used in microphones because the output is more immediately usable by most external devices compared to PDM. Indeed, other than the fact that PDM and I2S are both dual-channel interfaces, they’re completely dissimilar.

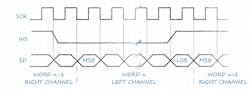

I2S looks like a standard data-transfer protocol with three different lines: a clock, data, and word select line (Fig. 2). “Word Select” indicates which channel, such as left or right, that the audio is transmitted from. There’s no universal clock speed for I2S. So, to send data at a rate that keeps up with a live audio stream, some calculations are necessary.

The industry standard for audio sampling is 44.1 kHz. Therefore, if we assume 16 bits of precision and a mono channel, the clock speed would need to be at least 705.6 kHz. If it becomes a stereo channel, double that to approximately 1.42 MHz to find the minimum clock speed:

Sample frequency × data precision × channel number = needed bandwidth

44,100 Hz × 16 bits × 2 channels = 1,411,200 Hz bandwidth

I2S uses an internal codec and built-in filter, which means the signal is immediately usable by a digital signal processor. Thus, while components that use I2S tend to be a little larger than their PDM counterparts, they don’t require the additional components to be processed. As a result, even though the individual components of a PDM system may be smaller and less expensive, overall, I2S tends to be the smaller option once all ancillary components are factored in.

Suitability for Different Use Cases

Comparatively, PDM has better noise immunity and bit error tolerance, and thus is preferable when audio quality is important, particularly when anticipating an environment full of extraneous electromagnetic radiation. I2S is simpler to implement and, in most cases, is less expensive and has a smaller footprint. In turn, it’s ideal for applications where size or cost are driving factors.

In more of an edge case, the lower frequency of the I2S signal makes it a better option for long-distance transmissions, such as when the microphone and processor are on different sides of a recording studio or performing arts center. If long-distance transmissions are required, an in-depth review will be necessary, as well as testing with the cabling that will likely be used.

Lastly, it’s important to note if there are DSP capabilities in a design. If so, the I2S device’s three signal lines and greater power consumption may make it more resource-intensive than PDM devices that can take advantage of DSP capabilities already on the PCB.

With the proliferation of MEMS microphones in voice-based applications as well as the increased demand for high-quality audio for music and other audio recordings, these different protocols have become more important. Considering such options and weighing the advantages and drawbacks of each solution will let designers decide which technology will work best for the project in mind.