The general industry trend is to make electronic products more efficient and, in general, consume less energy. One of the major considerations is to minimize the standby power of electronic circuits. This trend would seem to be commendable when viewed as an effort to be more conscious of our environment and when going “green.” The constant demand for smaller, smarter electronics with longer battery life also dictates higher efficiency and lower standby power. Is it possible, however, there can be a downside to improving efficiency?

Let’s consider a frequently used building block, the Low Noise Amplifier, or LNA. These amplifiers are generally less than 10% efficient and yet they are still used in critical applications for their superior linearity, very low harmonic content and ultra-low noise. It seems odd that it is necessary, or even appropriate, to power such an amplifier with a very high efficiency power supply, and yet the current trend in power electronics is ONLY towards on highly efficient power supplies as a one size fits all solution. A similar argument could be presented with regards to low jitter clocks -- the heart of most digital circuits.

You might wonder what the harm could be in creating power supplies that are too efficient or consume too little power. The answer is that there are consequential tradeoffs.

Beginning with the basic Shockley equation, the physics of a silicon junction, neglecting the bulk resistance of the junction, is described as:

Where:

VT = Thermal voltage (0.0259V at room temperature)

N = Emission coefficient (multiplying factor), often left off in transistor equations because transistors have coefficient of 1

IS = Device saturation current

IJ = Current in the junction

VJ = Voltage developed across the junction

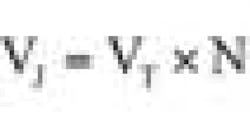

Evaluating the partial derivative of VJ with respect to IJ results in the small signal junction impedance, approximately defined by:

This simple relationship is the source of the first two challenges of reducing power consumption. The impedance of a single silicon junction is inversely proportional to the junction current, so lower bias currents result in higher junction impedances. To keep the component or circuit voltage noise low with higher impedances, we must create components that have lower noise currents.

A second challenge may be apparent from this simple set of equations. While silicon transistor junctions typically have an emission coefficient (N) of 1, it is not true for diodes or MOSFETs. Lower power circuits are often constructed from MOSFETs, so these impedances can be as much as an order of magnitude greater than for silicon BJTs.

The improved efficiency also impacts circuit noise in other ways. Increased resistor values are used to minimize the dissipated power. This is true in amplifier circuits, as well as in power supply circuits. The noise emission from a resistor is defined by:

where:

K = Boltzmann’s constant

T = Kelvin temperature

This relationship shows us that when we integrate noise over a frequency range of Δf the noise is proportional to the square root of the resistance, so that higher resistances increase noise, while the amplifier noise currents also multiply by the higher impedance, resulting in increased noise voltage.

A third problem is that the higher circuit impedances are more susceptible to external fields and so increased shielding may be required in order to manage noise levels.

Consider a simple linear regulator circuit such as shown in Fig. 1. Transistor Q1 represents the output transistor and capacitor C1 represents the output capacitor.

The transistor base emitter junction also follows Shockley’s equation, therefore the junction impedance is defined by Equation (2). Here, the current, IJ, is the regulator output current. It now becomes evident that there is a pole resulting from the junction impedance defined by:

There is clearly a pole that moves in proportion to the regulator output current. The lower the output current is the lower the pole frequency (fP). Unless the regulator is properly compensated for very low current operation, the stability will be poor. Poor stability dramatically impacts the closed loop characteristics such as noise voltage, PSRR and output impedance.

The measured results in Fig. 2 show the impedance of a voltage reference with bias currents of 1mA and 2mA. In both cases the reference has a 0.1uF ceramic capacitor across the output.

The peaking corresponds with the bandwidth and phase margin of the reference control loop. In general, the lower the output current, the more sensitive the stability is to the magnitude of the output capacitance.

Noise is also generated by the voltage regulator itself. In addition to the previously mentioned issues the voltage regulator also introduces noise internally. Not all regulators behave the same noise-wise, though in general, Low Dropout Regulators (LDOs), while offering improved efficiency, present much higher noise than linear regulators. In addition, linear regulators produce much higher noise than voltage references.

The results in Fig. 3 show the output noise spectrum of a typical LDO (yellow trace), an LM317 linear regulator (purple trace), a REF-03 voltage reference (green trace) and a custom regulator (blue trace). Most LDO regulators have higher low frequency noise than standard voltage regulators. It is also interesting to note that most linear regulators have spurious responses at low frequencies. In this case, the LDO has spurious signals at 3.5kHz (and harmonics) while the LM317 has spurious responses below 1kHz. While the magnitude of the noise is much lower than a switching regulator, sensitive electronics can still be negatively affected.

Higher Hoise

Replacing linear regulators with switching regulators results in significantly increased noise and EMI and, therefore, must be carefully considered.

This is not to say that it is not possible to improve the efficiency or reduce the power consumption of electronic circuits. It does say that we need to consider the impacts and ramifications, and in general, we should be making very careful performance measurements to evaluate the tradeoffs. While RF engineers use many classes of amplifiers, it is advisable for power engineers to also learn to use many classes of voltage regulators. Each type of regulator has its place, and when evaluated properly, a balance between performance and power consumption can be achieved. As a general rule, the low power circuits and reference sources must present the lowest noise. This is to say that we should generally be powering low power sensitive circuits with lower efficiency regulators, carefully designed for low noise and low output current. The higher power circuits are generally less susceptible to noise, though as device operating voltages continue to fall the noise margins will fall along with it, leaving us with tradeoffs.

Related Articles:

An Unconditionally Stable Linear Voltage Regulator

Are We Focused on the Wrong Reference Parameters?

A New Technique for Testing Regulator Stability Non-Invasively