Designed specifically for high-voltage sensing, a new generation of optically isolated amplifiers make monitoring and system protection circuits more accurate and easier to design. These iso-amps can also provide isolated temperature and current sensing.

Related Articles

- Characterizing High Power Semiconductors Requires New Technologies

- Test Equipment Must Keep Pace with New High Power Semiconductor Developments

- EMC Poses Challenge for Automotive Electronics

- AC Power Testing Presents Many Challenges and Concerns

- Test Saturation Voltage to Achieve High Efficiency #1

- Test Saturation Voltage to Achieve High Efficiency #2

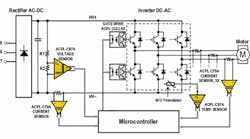

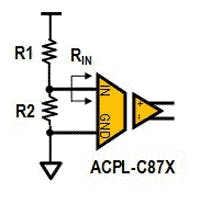

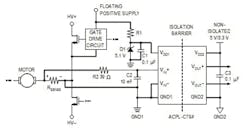

Fig. 1 shows a typical inverter in an ac motor drive. The inverter converts the dc bus voltage to ac power at a variable frequency to drive the motor. IGBTs form the heart of the inverter; they must operate at a high frequency and must be able to withstand high voltages.

With the use of appropriate power switching devices, signal isolators, and control circuits an inverter’s ac output can be set to any required voltage and frequency. The isolation amplifier in Fig. 1 (iso-amp) ACPL-C87A [1] works as a precision voltage sensor together with a resistive divider consists of R1 and R2, monitoring the DC bus voltage. The ACPL-C79A[2]works with a shunt resistor to provide accurate current measurement. This voltage and current sensing is performed even in the presence of high switching noise. The isolated voltage sensor ACPL-C87A can also be used in isolated temperature sensing designs. In this application, the voltage sensor must linearly and accurately measure temperature and send it across the isolation barrier thus providing safety insulation.

These voltage, current and temperature information from the iso-amps are collected by the microcontroller, which uses the data to calculate the feedback values and output signals needed to provide effective control and fault management in the power converters.

Optical Isolation Amplifiers

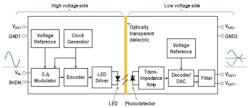

As an example, functional blocks of the ACPL-C87A are shown in Fig. 2.

First the isolation amplifier senses the input voltage (single-ended analog signal) and converts it to a digital bit stream. The bit stream is then transmitted across the optical coupling pair consisting of an LED and a photodetector. This optical signal path provides the electrical insulation barrier. Because the transmitted signal is optical rather than electrical, it is immune to magnetic fields and electrical noise. The photodetector recovers the optical signal and converts it back to an electrical signal, which is decoded and filtered to reproduce an analog output signal. The output voltage, provided in differential mode for better common mode noise rejection, is proportional to input voltage with unity gain.

The voltage sensor ACPL-C87A provides ±1% measurement accuracy. Other options include ±0.5% (ACPL-C87B) and ±3% (ACPL-C870). The ACPL-C87X family features a stretched SO-8 package that is 30% smaller than a DIP-8 package. These iso-amps have a double protection rating of 5000 VRMS/1 min per the UL 1577 safety standard. The 1414 VPEAKmaximum working voltage specification per IEC/EN/DIN EN 60747-5-5 ensures circuits on the low voltage side are not damaged by hazardous high voltages.

The current sensor ACPL-C79A shares all the key functional blocks of the ACPL-C87A as shown in Fig. 1, except that the former is configured as differential inputs (VIN+, and VIN-) instead of a single-ended input (VIN) and shutdown (SHDN). The other differences between the voltage sensor and current senor are input range and gain settings. The ACPL-C87A accurately measures a 0-2 V input signal, while the ACPL-C79A measures ±200 mV linear input range. The different input ranges are optimized for voltage sensing and current sensing respectively. The ACPL-C87A has unity gain, while the ACPL-C79A is configured with 8.2 times gain. The ACPL-C79A family shares the same package and insulation capability as that of the ACPL-C87X family.

Voltage Sensing

Using the ACPL-C87X as an isolated voltage sensor is straightforward. You can select resistors to form a voltage divider to scale down the voltage signal to be measured to a level within the sensor input range. With an integrated isolation and sensing circuit, the application circuit is significantly simplified compared to alternative solutions that employ separate devices to perform sensing and isolation functions.

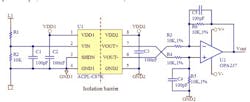

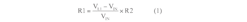

A detailed voltage sensing circuit with the ACPL-C87X is shown in Fig. 3. Given that the ACPL-C87X’s nominal input voltage for VINis 2 V, a user needs to choose resistor R1 according to Equation 1:

VL1is the voltage at L1 in Fig. 3. If VL1is 600 V and R2 is 10 kW, then the value of R1 is 2990 kW.

Choosing resistors is flexible. One method is to combine several resistors to match the target value; for example, 2 MW, 430 kWand 560 kWresistors in series make 2990 kWexactly. A VINof 2 V corresponds to a VL1of 600 V. However, in the cases that VL1is not 600 V, specific resistance values might be difficult to find. Another method is to round up the target value to a convenient value, for example 3 MW, to make resistor selection easier. In such cases, the scaling relationship may need fine-tuning. In the same example with a VL1of 600 V, R1 of 3 MW, and R2of 10 kW, VINis solved to be 1.993 V.

The down-scaled input voltage is filtered by the anti-aliasing filter formed by R2 and C1, with corner frequency of 159 kHz(the value of R1 is usually much larger than R2, therefore neglected in calculation), and then sensed by the ACPL-C87X. The galvanically isolated differential output voltage (VOUT+-VOUT-) is proportional to the input voltage. The OPA237, configured as a difference amplifier, converts the differential signal to a single-ended output. This stage can also be made to amplify the signal, and, if required, low-pass filter the signal to limit bandwidth. In this circuit, the difference amplifier is designed for a gain of one with a low-pass filter corner frequency of 15.9 kHz. Resistors R5 and R6 can be changed for a different gain. The bandwidth can be reduced by increasing the capacitance of C4 and C5. The isolated output voltage VOUT, which is linearly proportional to the line voltage on the high voltage side, can be safely connected to the system microcontroller.

With the ACPL-C87X gain of 1, the overall transfer function is simply:

or

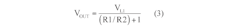

The input stage of the application circuit in Fig. 3 can be simplified as shown in Fig. 4. R2 and RIN, the input impedance of the ACPL-C87X, create a current divider that results in an additional measurement error component that will add on top of the amplifier gain error. With the assumption that R1 and RINhave a much higher value than R2, the resulting loading error can be estimated to be R2/RIN.

With an RINof 1 GWfor the ACPL-C87X, the loading error is negligible for R2 values up to 1 MW, where the error is approximately 0.1%. Though this error is small, it can be reduced by lowering R2 to 100 kW(error of 0.01% approximately).

Current Sensing

As shown in Fig. 5, using the isolation amplifier to sense current can be as simple as connecting a shunt resistor to the input and getting the differential output. By choosing an appropriate shunt resistance, any range of current can be monitored, from less than 1 A to more than 100 A. In operation, currents flow through the shunt resistor and the resulting analog voltage drop is sensed by the ACPL-C79A. A differential output voltage is created on the other side of the optical isolation barrier. This differential output voltage is proportional to the current and can be converted to a single-ended signal by an op-amp or sent to the controller’s ADC directly.

One of the benefits of using an isolation amplifier is that one sensor can fit in all the models with the shunt changed accordingly. The designer can then focus on optimizing sensor performance and easily port over the design to other models.

Selecting a shunt is easy. For example, if a compact motor has a maximum current of 10 Arms and can experience up to 50 percent overload, then the peak current is 21.1 A (= 10 ´1.414 ´1.5). Assuming the sensor input voltage of 200 mV for optimal performance, the shunt resistance would be about 10 mW. The maximum average power dissipation is about 1 W. Various shunt resistors are available to fulfill this type of application need. They are offered in a case size of 2512 or similar at an inexpensive price, featuring a 3W power rating, decent tolerance and temperature coefficient.

Over-current conditions in an IGBT can occur due to a phase-to-phase short, a ground short or a shoot through. The shunt + iso-amp current sensing devices on the output phases and DC bus provide fault detection in addition to current measurement (Fig. 5), and the requirement is fast response to current surges.

The ACPL-C79A has a fast 1.6 µs response time with a step input. This allows the iso-amp to capture transients during short circuit and overload conditions. The signal propagation delay from input to output at mid point is only 2 ms, while it takes just 2.6 ms for the output signal to catch up with input, reaching 90% of the final levels [2].

Besides fast response time, the ACPL-C79A provides ±1% gain accuracy, excellent nonlinearity of 0.05% and a signal-to-noise ratio (SNR) of 60 dB. Also available is the ACPL-C79B, which offers a higher-precision gain accuracy of ±0.5%, and the ACPL-C790, which has a ±3% gain tolerance.

Isolated Temperature Sensing

Thermistors are widely used to measure temperature. Galvanic isolation between the potential of the thermistor and that of the system analog-to-digital converter is often required, especially when the thermistor is mounted near high voltages or in electrically noisy or poorly grounded environments. A lack of isolation can impair safety and induce electromagnetic interference (EMI).

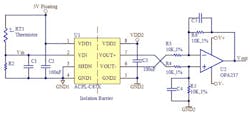

A simple isolated temperature sensor circuit is shown in Fig. 6. RT1 and R2 form a voltage divider from the floating, constant 5 V voltage source that also powers the voltage sensor. Choose RT1 and R2 so that the voltage fed into the ACPL-C87X isolation amplifier does not exceed the full-scale range of 2.46 V. The high impedance input terminal of the ACPL-C87X allows a relatively high resistance of R2 without causing a significant loading error. Select the resistor and capacitor values after reviewing the thermistor manufacturer data sheet.

References

1. ACPL-C87B/C87A/C870 Precision Optically Isolated Voltage Sensor Data Sheet. Avago Technologies, AV02-3563EN.

2. ACPL-C79B/C79A/C790 Data Sheet, Avago Technologies, Publication No. AV02-2460EN.

3. HCPL-7840 Isolation Amplifier Data Sheet. Avago Technologies, AV02-1289EN.

4. HCPL-7800A/7800 Isolation Amplifier Data Sheet. Avago Technologies, AV02-0410EN.