Get Started On Your LXI-Compliant Instrument Design

The LXI Standard is an exciting communications protocol development for the testand- measurement industry. Unfortunately, members of the Consortium have been the primary writers associated with the information published regarding the LXI Standard.

Since, having participated in its development, they also possess an intimate knowledge of the standard, they have also been able to quickly develop products that leverage off this technology. Thus, it has left a gap in the published information in regards to newcomers who need to develop LXI-compliant instruments.

This article’s intent is to provide an overview of the primary elements required for developing LXI-compliant instruments, optional strategies for developing these elements, and access to valuable resources that will assist in completing that development process.

WHAT IS LXI? The LXI specification extends the capabilities of typical Ethernet by addressing key functional areas that are necessary to ensure instrument interoperability, performance, and usability. The specification is divided into key functional areas, which enables product certification based on specific “Class” requirements.Class A encompasses all of the benefits of LXI. It is the class of choice for systems that require instrumentation to be tightly integrated and synchronized. Synchronization is based on the IEEE-1588 Precision Time Protocol, which adds the dimension of time to the system designer’s arsenal.

LXI test-and-measurement modules are optimized for use in design validation and manufacturing test systems, with LAN connectivity enabling modules to be accessed from anywhere in the world. Unlike modular card cages that depend heavily on a host controller, LXI modules are self-contained.

Each module contains its own processor, LAN connection, power supply, and trigger inputs. These attributes allow for instrument-toinstrument communication completely independent of a host controller. When compared to legacy test-and-measurement standards, this revolutionary concept opens the door to a variety of state-of-the-art application strategies.

LXI Class A products provide built-in Web servers, a standard for triggering and synchronizing between standalone instruments, and peer-to-peer communication

Introduced in 2005, the LXI standard has been adopted by more than 50 companies. To date, more than 500 products have been certified as compliant with the LXI standard, with annual sales of LXI-equipped test-and-measurement equipment now exceeding $200 million. The LXI standard creates new capabilities that optimize test throughput, overall system performance, and cost efficiency in a way that lets engineers build powerful, Web-enabled test systems in less time.

The LXI Consortium is a non-profit corporation that comprises test-andmeasurement companies. The group’s goals are to develop, support, and promote the LXI standard. LXI’s flexible packaging, high-speed I/O, and standardized use of LAN connectivity address a broad range of commercial, industrial, aerospace, and military applications.

CONSIDERATIONS FOR LXI COMPLIANCE Prior to developing an LXI-compliant instrument, there are three distinct factors to consider:

1. Whether or not to join the Consortium.

2. Which LXI Class, or level of compliance, will define the instrument being developed.

3. The components, both hardware and software, that will be required by the instrument.

WHETHER OR NOT TO JOIN THE LXI CONSORTIUM

Obviously, the Consortium would like organizations that are developing LXI instruments to join. But, over and above that, there are specific benefits to being a member.

Members have access to a wide array of information resources, not the least being the other members of the Consortium, who are intimately familiar with the LXI Standard. Members also have access to the fully annotated versions of the LXI specifications, which contain additional background information, rationale for specific decisions, and additional explanatory commentary.

In addition, member-only dialogues are a rich and valuable resource of information. Consortium working groups have weekly teleconferences, and many members meet face to face frequently at general meetings. Most importantly, however, membership is the best way to gain the privilege of using the LXI logo on the instrument and advertising material.

WHICH LXI CLASS IS MOST APPROPRIATE?

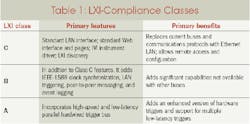

LXI compliance is divided into three classes: Class A, B, and C (Table 1). Class C is the minimum feature set that all LXI devices must provide. The decision to extend your instrument’s compliance to Class B or A would depend on the intended applications.

Each class represents a corresponding increase in developmental effort as well as cost. Determining which class is appropriate requires an understanding of the functional blocks and implementation options for each of the classes. Each class has a unique set of required components, as well as optional features and functionality that may be incorporated at the discretion of the designer.

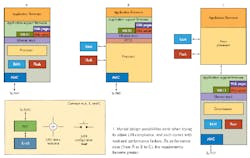

CLASS C COMPONENTS Several major components are required to implement Class C functions, hardware, and firmware (Table 2). While not all commercially available networking components will meet the requirements of the LXI specification, this table details the most notable LXI-specific requirements. There are multiple design possibilities, and each can significantly affect the cost and performance (Fig. 1).In Figure 1, “A” illustrates an implementation suitable for devices with minimal performance requirements and processing capability above that required for networking support. It uses a lowcost microcontroller with integrated networking support that’s also employed for all the other computational and control tasks within the device.

“B” is suitable for devices with greater performance requirements. A single high-end microcontroller provides networking and application support, as well as better performance and capacity for application tasks.

“C” is an implementation for high-performance devices that must perform significant computational and control tasks within the application. It uses multiple high-end microcontrollers to handle networking functions and application tasks.

Two factors drive Class C architecture and design decisions: required level of networking performance and the computational and control load of the rest of the device. Networking requirements are driven by the maximum network speed (10 Mbits/s, 100 Mbits/s, 1 Gbit/s, or more) and required data-throughput rate.

If Class C functions are being implemented within a Class A or B device, keep in mind that it places additional demands on both the networking performance and the general computational load, particularly with Class B.

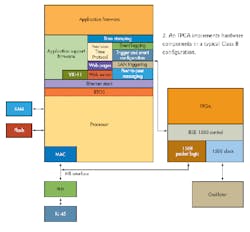

CLASS B COMPONENTS Components required for Class B support are mainly those needed to implement IEEE 1588 clock synchronization. For this discussion, a combined hardware/ firmware approach (recommended by the LXI Consortium) is assumed. This ensures that adequate performance levels are met. In addition to the components required for Class C, Class B requires its own set of components (Table 3).There are several options for implementing Class B functions. A typical setup would use an FPGA to implement the hardware components (Fig. 2). Several commercial sources for HDL code and firmware for implementing 1588 functions are available (see “Additional Information” at the end of the article). Open-source options are available as well.

Alternatively, several vendors offer microcontrollers that have built-in hardware support for 1588 along with firmware libraries for the firmware components. At least one manufacturer now offers a physical-layer (PHY) chip with integral support for IEEE-1588.

The IEEE recently adopted version 2 of the 1588 standard (IEEE 1588-2008), which makes significant alterations to version 1. Some of the available components listed implement the version 1 standard. Designers should discuss the availability of version 2 components before beginning a new design.

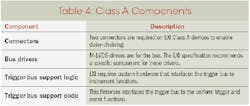

CLASS A COMPONENTS

Additional components are required to implement the wired trigger bus (Table 4). The LXI specification provides a reference for the bus driver circuitry. This bus driver circuitry is critical to correct bus interoperability. Other guidelines cover the equally critical printed-circuit-board (PCB) layout.

The LXI Consortium published a separate specification covering the wired trigger bus cable and terminator details. That’s because most of the development work associated with Class A will involve connecting the bus to internal functions and writing the firmware support functions.

DEVELOP AN LXI-COMPLIANT INSTRUMENT At this point, you have all of the information needed to select a class and develop an LXI-compliant Instrument. Simply select the LXI class for your instrument based on your application and requirements, and design, implement, and test your instrument.To market an instrument as LXI-compliant, it has to pass compliance testing. To accomplish this:

• Perform in-house testing of all LXI functions using the materials available to members on the LXI Web site.

• Have the instrument tested by a Consortium member or other third-party compliance tester. This can be done at one of the several annual LXI PlugFest and general membership meetings.

Once the instrument is tested, submit the results and other required documentation to the Consortium for review and approval. If approved, you will receive certification of compliance. At that point, the LXI logo can be affixed to the device and marketed as LXI-compliant. If you have not joined the Consortium, you will need to become a licensee.

ADDITIONAL INFORMATION Additional information about membership, planned events, LXI products, and access to the public version of the LXI specifications is available at www.lxistandard.org.For Class C, information on IVI drivers and specifications is available at www.ivifoundation.org. There’s also a validation program for Web pages at www.w3c.org. Information on microcontrollers with embedded networking support can be found at www.microchip.com, www.digi.com, www.rabbitsemiconductor.com, and www.netburner.com.

For Class B, general information on the IEEE1588 standard is available at http://ieee1588.nist.gov/. Information on microcontrollers with hardware support for IEEE 1588 is located at www.intel.com, www.freescale.com, and www.amcc.com. For information on a PHY chip with integral IEEE 1588 support, go to www.national.com.

For Class A, a recommended source for M-LVDS line drivers SN65MLVD080 (eight-channel) or SN65MLVD201 (singlechannel) is found at www.ti.com. Also, for information on wired trigger-bus cables, go to www.circuitassembly.com, or wired trigger-bus cables plus accessories, go to www.pickeringtest.com.

About the Author

Paul Franklin

Paul Franklin is project manager, semiconductor test systems, for Keithley Instruments in Cleveland, Ohio, which is part of the Tektronix test and measurement portfolio. Before joining Keithley in 2000, he gained more than 20 years of measurement and control industry experience as an engineer and a manager with electronic controls and industrial automation firms. He earned his BSEE and MSE degrees at Case Western Reserve University, Cleveland. Also, he is a member of IEEE, IEEE-CS (Computer Society), and ACM (Association for Computing Machinery).