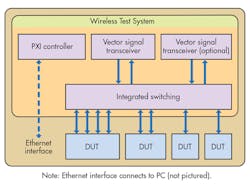

Two characteristics of NI’s Wireless Test System (see "Best of 2015: Wireless System Solves High-Volume Product Test Problems") allow it to speed up testing while lowering production test costs—the PXI modular system and the NI vector signal transceiver (VST).

PXI, or PCI eXtensions for Instrumentation, is a standard created by NI in 1997. It uses the high-speed PCI bus to interconnect measurement modules together to form specialized electronic test equipment and laboratory instruments. The result is a custom product built of special modules to create an instrument for a unique purpose. PXI has become an industry standard supported by a consortium called the PXI Systems Alliance (PXISA), which includes over 70 companies.

A PXI product begins with a chassis and power supply featuring a Compact PCI bus structure that supports multiple plug-in modules (the faster PCI Express bus is an option). A typical PXI chassis begins with a controller, a PC in a PXI format that usually runs Windows 7. The instrument is then constructed with multiple modules for specific measurements. Some of the possible modules include counters and timers, digital multimeters, LCR meters, digitizers, oscilloscopes, dynamic signal analyzers, digital I/O, RF signal generators, and vector signal analyzers, among many others.

The great benefit of the PXI system is that modules from different manufacturers are fully compatible with the standard. So, they can be mixed and matched to create the specific instrument to fit a particular application’s demands. The end result is a low-cost system that can easily be expanded or otherwise modified by adding new modules. Manufacturing test is a typical application.

One of the unique PXI modules available is NI’s VST. It combines a vector signal generator, a vector signal analyzer, and a programmable FPGA. The FPGA allows the instrument to be programmed with LabVIEW, like a software-defined radio, to accommodate many different modulation schemes. For example, the VST can test Wi-Fi products using the latest 802.11ac standard as well as cellular handsets using LTE-Advanced.

The NI VST comes in several different models, designated PXIe-5644R/5645R/5646R. Basic specifications include a frequency range of 65 MHz to 6 GHz, 80- or 200-MHz bandwidth, 24 channels of high-speed digital I/O, user-programmable FPGA, and an optional I/Q interface. The VST is nearly an ideal test instrument for most wireless technologies.