Download this article in PDF format.

Do you have a project that could be significantly improved with the new CAN FD features? If so, ICs called system basis chips (SBCs) can solve your problem fast. CAN, of course, is the Controller Area Network, a serial data bus that’s widely used in automotive networks and interfaces in industrial equipment.

This incarnation of CAN—CAN FD (flexible data rate)—with its faster data rate and other features markedly enhances the performance of all CAN buses. Here’s a good way to add the CAN-FD interface to your current or next design.

Sponsored Resources:

- System basis chips 101 - A beginner's guide to CAN, CAN FD and LIN SBCs

- The need for even more speed: CAN FD

- Upgrading to CAN FD: TCAN4550-Q1 SBC overview

CAN Fundamentals

Classical CAN was developed by Bosch back in the 1980s. Since then, it has been adopted by the automotive industry for efficient connections between equipment in vehicles. Practically all cars and trucks on the road today contain CAN. CAN also has a heavy presence in industry to connect a wide range of machines and electronic products. It’s so popular that many microcontrollers contain an integrated CAN transceiver. Here’s a summary of the basic features and characteristics of CAN:

- Multidrop differential bus that can handle up to 127 nodes.

- The transmission medium is a shielded or unshielded twisted pair with 120-Ω terminations.

- Data transmission is by standard asynchronous bytes with start and stop bits.

- Access method is carrier-sense multiple access with collision detection (CSMA/CD).

- The protocol frame permits a maximum data block of 8 bytes and uses a 16-bit cyclic redundancy check (CRC) for error detection.

- Maximum data rate is 1 Mb/s up to 40 meters. Range can be extended to a limit of 1000 meters using data rates down to 40 kb/s.

- CAN is an international standard; ISO-11898, ISO-11519, and others.

- Has overall good noise immunity.

Despite its modest specifications, it’s been widely adopted for its robustness and reliability.

CAN FD

The immediately apparent basic features of CAN flexible data rate, which are mostly sought by automotive manufacturers, include:

- Transmit more data per protocol frame—a basic frame can now carry up to 64 bytes.

- Reduced protocol overhead at the higher networking layers.

- A longer CRC (up to 21 bits) improves error detection.

- Higher basic data rate up to 3.7 Mb/s. Depending on the quality of the cable and its length, and number of nodes, higher data rates are possible extending into the 10-to 12-Mb/s range.

These improvements are highly desirable for new designs. However, many system MCUs don’t integrate CAN or CAN FD circuitry. This problem can be solved with an SBC.

System Basis Chips

SBCs are special ICs that combine a CAN or CAN FD controller and interface along with a power circuit like an LDO on a single chip. An SBC is a good solution when you need additional output power or layout options that may also require a discrete solution using both a transceiver and discrete LDO or dc-dc converter.

A good example of such an SBC is Texas Instruments’ (TI) TCAN4550-Q1. It provides full CAN and CAN FD functionality meeting the latest ISO-11898 standards and is AEC-Q100-qualified for automotive applications with a −40 to 125°C temperature range. The SBC supports CAN FD data rates to 8 Mb/s, but is also backward-compatible with Classic CAN.

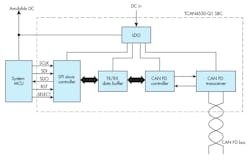

This simplified diagram shows the major parts of the TCAN4550-Q1 system basis chip (SBC). The communication link between the SBC and the system microcontroller is the System Peripheral Interface (SPI).

The figure shows how the SBC is used. It’s connected to the system MCU by way of the System Peripheral Interface (SPI) bus—the SPI is a standard interface on most MCUs. The SBC connects to the CAN bus. The TCAN4550-Q1 is powered by an on-chip low-dropout (LDO) regulator that can also provide up to 70 mA at 5 V for external devices. In addition, the SBC’s integrated watchdog feature allows designers to eliminate this feature from the MCU. The TCAN4550-Q1 comes in a 20-pin, 3.5- × 4.5-mm SOIC package.

Note: TI also has an SBC for the popular Local interconnect network (LIN) interface, which is another widely used automotive interface. The TLIN1441-Q1 incorporates a full LIN transceiver plus the LDO. It permits full and quick addition of LIN to an existing design.

Evaluation kits and reference designs for both CAN FD and LIN are available to help expedite a design.

Sponsored Resources: