Analog Devices Inc. (ADI) and First Sensor AG, a developer of standard and customer-specific sensor solutions, announced that they will collaborate on developing products aimed at speeding the launch of autonomous sensing technology for unmanned automotive, aerial, and underwater vehicles. As part of the collaboration, the two firms aim to shrink the LiDAR signal chain to enable higher system performance as well as reduced size, weight, power, and cost for manufacturers of sensing/perception technology targeting autonomous systems.

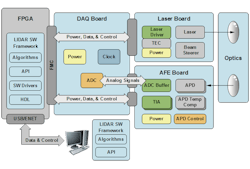

The companies also plan to develop other LiDAR products that will serve industrial manufacturing applications. LiDAR, by way of review, stands for “light detection and ranging,” and is a depth perception method that transmits a light source to do either ranging or create multidimensional depth maps of the scene of interest (see figure).

“The first step in our working together is to optimize ADI’s industry-leading transimpedance amplifiers (TIAs) with First Sensor’s avalanche photodiodes (APDs) so we can offer our customers more powerful and efficient LiDAR solutions, and better support the mass commercial launch of LiDAR systems into the autonomous transportation market,” says Stewart Sellars, general manager, LIDAR, Analog Devices.

Shown is a simplified schematic of a LiDAR system. (Source: Analog Devices)

The transimpedance amplifier presents a low impedance to the photodiode and isolates it from the output voltage of the operational amplifier. Recent related ADI developments include multichannel TIAs specifically designed to convert wide-dynamic-range photocurrent into a low-impedance voltage signal.

In addition to TIAs, Analog Devices’ signal-processing solutions directly enhance the capabilities of LiDAR systems. ADI’s product portfolio offers low-noise DACs and comparators, high-speed multichannel ADCs in the gigasample-per-second range, IQ demodulators and a host of power products for sensitive power-management architectures.

First Sensor brings to the partnership significant experience in manufacturing LIDAR APDs, which are highly sensitive detector arrays that convert light into photocurrent, measuring light pulses in the nanosecond range.

First Sensor’s Series 9 avalanche photodiodes were developed specifically for LiDAR and laser rangefinders. The series provides fundamental technology for the development of arrays with multiple individual sensors, e.g. 8, 16, and 32 pixels. Main features of the Series 9 APDs include very high sensitivity in the 905-nm range, wide dynamic range, and fast rise time.

Optimizing the interconnection between the APDs and TIAs is critical as it significantly influences the noise floor and bandwidth achieved. Improvements in these two parameters directly translate to LiDAR systems that can detect objects at longer range and with higher precision.

“The market for LiDAR systems is maturing, with customers expecting a renewed focus on implementing economically and technically compatible solutions,” says Dr. Dirk Rothweiler, CEO of First Sensor. “Adapting APDs and TIAs to each other is a logical next step in this evolution. By expanding our cooperation with Analog Devices, our customers will benefit from better LiDAR receiver performance.”

First Sensor and Analog Devices will each offer a common evaluation board with which system manufacturers can test the combined solution.

This cooperation with First Sensor marks Analog Devices’ next phase in implementing its Drive360 autonomous-driving solutions strategy. ADI’s Drive360 suite of technologies leverage its core competencies in high-performance MEMS, RF/mmWave, and photonics/optics technologies, allowing the company “to provide the automotive industry with holistic solutions and be a dedicated partner for highly automated and autonomous driving technology needs,” according to a company statement.