Safety and brand differentiation are two of the leading factors driving greater adoption of LEDs in automotive front-lighting platforms, which are growing at 30% per year, according to Strategy Analytics Inc. (Fig. 1). But while matrix LED headlights enhance safety, not long ago they were exclusively the province for the premium auto sector, due to their complexity and high cost. Other design challenges include the need for increased power as well as thermal design complexity.

1. As part of their distinctive brand identities, OEMs are designing in advanced safety features such as glare-free high beams along with LED and matrix lighting. (Source: Maxim Integrated)

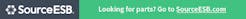

The MAX20092, a 12-switch matrix manager IC for automotive lighting applications developed by Maxim Integrated, looks to break that mold (Fig. 2). The device enables designers of high-performance automotive matrix lighting and adaptive driving beam light-emitting-diode (LED) applications to migrate to higher current devices while reducing solution size and improving design flexibility.

"Maxim designed the MAX20092 to help developers who want to utilize more LEDs in their designs and reduce the BOM cost and solution space," says Yin Wu, business manager for the Automotive Business Unit at Maxim Integrated. "The safety and OEM branding value that LEDs present are compelling, and we enable their adoption in greater numbers through higher flexibility and reliability."

The IC includes a 12-switch array for bypassing individual LEDs in a single- or dual-string application. It minimizes thermal issues associated with LED matrix lighting applications by offering what Maxim says is the industry's lowest internal switch resistance (RDS_ON) of 70 mΩ, 65% lower than the closest competitive solution. Low on-resistance minimizes conduction loss and power dissipation.

2. Shown is a simplified block diagram of the MAX20092. (Source: Maxim Integrated)

A single current source can be used to power all of the LEDs connected in series. Individual LEDs can be dimmed by turning on and off the bypass switches across each LED, and are configurable as two strings with six switches in series per string and four strings with three switches per string. A separate current source powers each string. Each switch can be connected across one or two LEDs in series.

The part includes an internal charge pump that provides power for the gate drive of each LED bypass switch. The IC further features fault protection and management for open, short, and open-trace LED detection as well as a serial peripheral interface (SPI) for serial communication. The MAX20092 is a slave device that uses the SPI to communicate with an external microcontroller, which is the master device.

The 12 switches can be independently programmed to bypass the LEDs across each of the switches in the string. Each switch is able to be turned fully on, fully off, or dimmed with or without fade-transition mode. Pulse-width-modulation (PWM) frequency can be set by an internal oscillator or set to an external clock source.

The MAX20092 comes in a 32-pin (5 × 5mm) side-wettable TQFN (SWTQFN) package with a thermally enhanced exposed pad.

Maxim also introduced the MAX20096 and MAX20097 dual-channel, synchronous buck high-brightness LED controllers to work with the MAX20092. These help designers improve transient response times in LED lighting with the company’s proprietary average current-mode control scheme, also said to minimize EMI.

To assist designers, Maxim is making available the MAX20092EVSYS# evaluation kit that includes a graphical user interface, matrix manager board, and an LED adapter board featuring Osram Opto Semiconductors' Oslon Compact PL, KW CELNM1.TG, LED components, which are suitable for adaptive matrix-style headlights.