This file type includes high resolution graphics and schematics.

Conventional magnetic reed relays provide excellent low-power characteristics combined with a low level of electrostatic discharge (ESD) sensitivity, reasonably good high-power switching capability, long switching lifetimes, high magnetic sensitivity, and low costs. But they’re limited in how small they can be made.

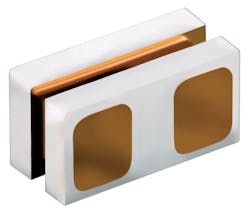

The RS-A-2515 RedRock switch from Coto Technology solves the size problem yet retains all of the high-performance properties of classical magnetic reed switches. It is the industry’s smallest micro-fabricated magnetic reed switch with a footprint of less than 2.1 mm2 (1.01 by 2.08 mm) and a height of just 0.94 mm (Fig. 1).

The surface-mount technology (SMT) device targets the sweet spot of magnetic switching applications by combining zero power operation and high-current hot switching capability in a small package, compared to other magnetic switching technologies.

It features an operating range of 10 to 25 milli-Teslas (mT) and a release range of 5 to 15 mT. It also can switch 300 mW and handle voltages of 100 V dc (70 V ac rms) and currents of 50 mA dc (35 mA ac rms). Contact resistance is just 3 Ω (7 Ω maximum). And, its breakdown voltage rating is 200 V dc.

Related Articles

• SMT Reed Switches Promote High-Density Design

• SMT Microminiature Detect Switches Boast 100,000-Cycle Lifetime

• Mini Reed Relays Optimized For High-Voltage Apps

Manufactured using high-aspect-ratio micro-fabrication (HARM), a MEMS-based process, it offers much higher magnetic sensitivity and high-power switching capability than planar MEMS switches. A structure can be grown at a height orders of magnitude greater than its width. Yet the HARM process allows the RedRock switch to be offered at a relatively low price that’s cost-competitive with conventional reed switches when other superior parameters are considered.

Like MEMS IC manufacturing, the HARM process is a micromachined batch process. The RedRock switch is hermetically sealed and is made using wafer-level packaging (WLP), which allows it to achieve the inherent benefits of MEMS processing, namely a small size, low-cost manufacturability, and item-to-item reproducibility, as well as comparatively good to excellent performance parameters.

The RedRock’s contact blades are grown upward from the ceramic base of the switch using a lithographically produced sacrificial mold relative to the switch’s substrate. The precise dimensions of this mold and its extremely parallel walls ensure that the thickness of the reed switch blade and the contact gap are controlled to within a fraction of a micron (Fig. 2).

Unlike a typical planar MEMS switch where the blades move parallel to the substrate, the HARM process allows the blades to be made as wide as possible. Also, its footprint isn’t increased no matter how wide the blades are made, enabling higher current handling, lower contact resistance, and longer life.

The RedRock’s metal cantilever bridges two massively electrically isolated metal blocks that act as magnetic amplifiers, much like the external leads in a conventional reed switch. Magnetic flux from an external magnet builds up in a small gap between the cantilever and one of the blocks and pulls the cantilever into electrical contact with the block. The contacts are coated with ruthenium for maximum contact longevity.

Compared to a planar rhodium-coated-contact MEMS switch structure, the Red Rock’s blade is 1500 µm long (versus 550 µm for the planar MEMS switch), 200 µm wide (versus 100 µm), and 25 µm thick (versus 6 µm). A contact gap of 4 µm is used in both types of switches.

Although the RedRock switch requires 400 µN of closure force (versus 21 µN) and 45 µN for opening (versus 6 µN), it has vastly improved performance in a contact resistance of just 3 to 5 Ω (versus 500 to 1000 Ω) and a breakdown voltage of 200 V (versus 75 V). It also can carry a greater maximum current. The minimum melt current is 250 mA versus 0.7 to 14 mA.

Designed for high-performance applications that require extremely small switch size, the RedRock suits ingestible endoscopic capsules, insulin delivery for implantable pumps, and hearing aid switches. In the automotive sector, applications include level sensing for brake-fluid reservoirs.

The RS-A-2515 RedRock switch is available from stock in evaluation quantities at a unit price of $29.95. Also available from stock is an evaluation kit, EVAL, that sells for $49.95 each.

Coto Technology

This file type includes high resolution graphics and schematics.