What you'll learn:

- Benefits derived from numerical simulation

- Evaluating and validating the performance of an LED via simulation and cooling strategies.

- How to perform CHT simulation.

The global electronics industry generated US$997 billion in revenue in 20181 and is expected to grow at a compound annual growth rate (CAGR) of 5.6% until 20242. The demand for new products with enhanced performance is fueling the efforts of companies to continuously innovate and shorten their time to market.

This innovation requires efficient R&D departments as well as efficient design and testing processes. For the latter, engineers often employ numerical simulation to compare different designs to find the best design for an electronic system or component.

Why is Numerical Simulation Important?

The most impactful decisions are made early in the design process. At this stage, numerical simulation (or computer-aided engineering, CAE) plays a fundamental role in ensuring good energy efficiency, low failure risk, proper cooling, and high system performance. CAE enables a complex testing process through the simulation of a product’s physical properties in different conditions and environments.

The standard numerical simulation workflow begins with creating an initial design (CAD model), meshing it, adding boundary conditions, setting up the parameters, running the analysis, and finally post-processing the results. The simulation results are then analyzed to improve the design.

In an iterative design process, those steps are repeated until requirements are met and the optimum design is identified. This supports faster product development and eliminates or reduces the number of required physical prototypes in later design stages.

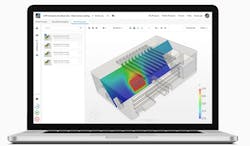

While numerical simulation has been around for several decades and its benefits known, native cloud applications for simulation technology have emerged as a new alternative.

The Benefits of Cloud-Based Numerical Simulation

All cloud-native applications are indigenous to the cloud, meaning they’re only built for and deployed within the cloud environment. For a computationally intensive technology like numerical simulation, the cloud is actually a perfect fit. Its main benefits include:

- Accessibility: Traditional simulation software needs to be installed locally on expensive high-performing computers, the majority of which remain idle most of the time. With cloud-based solutions, all that’s needed is a web browser.

- Scalability: The cloud gives access to different computational resources, depending on the need at a particular time. This also applies to storage. When more complex numerical simulations need to be run, the power can be increased.

- Pricing: Cloud-based solutions are highly cost-effective as they eliminate the need for heavy hardware investment. They’re usually delivered as SaaS applications (software as a service), which allows customers to pay on a subscription basis.

- Know-how: Most modern tools are designed for experts and experienced simulation engineers. Cloud-based simulation providers usually focus on ease of use and offer training and live support to help with onboarding.

Case Study: Thermal Management of an LED

Thermal management is one of the most essential factors engineers need to consider for LED lighting systems, as well as any electronic system for that matter. Failure to adhere to operational temperature limits can result in component overheating, shorter life cycles, costly faulty returns, system failure, and even pose dangerous risks to end users.

To mitigate these risks, critical temperatures need to be predicted in the design phase. This used to be a cumbersome task when dealing with complicated and detailed models, such as electronics or lighting systems. Before the emergence of thermal simulation and computational fluid dynamics (CFD), these variables could only be partially estimated using full-scale experiments, worst-case scenario estimations, and approximated design rules.

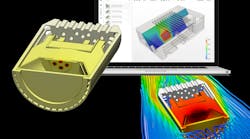

The following case study will demonstrate how engineers can utilize electronics cooling strategies and numerical simulation to accurately evaluate and validate the performance of an LED spotlight. Through cloud-based CFD, users can test their CAD models in a short amount of time and with minimum costs. This simulation is run on the SimScale cloud-based simulation platform (Fig. 1).

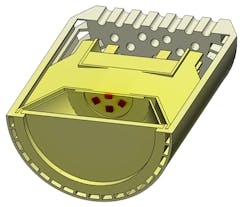

The LED spotlight generates 9 W of thermal power, and is a fairly common, as well as energy-efficient, household lighting apparatus.

The conjugate heat transfer (CHT) analysis type is selected, as it solves both the conduction and convection heat transfer phenomenon. By using CHT, the distribution of the temperature through the heatsink and the other solid components will be computed, taking into account the convection from the airflow (Fig. 2).

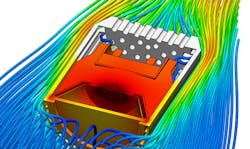

Through CHT simulation, the aim is to confirm that the junction temperature is kept under the 90°C operational limit to prevent overheating. The simulation results will give an evaluation of the dissipation when a natural/passive cooling strategy is chosen (Fig. 3).

From the simulation, it can be determined that the chips have their temperature kept at 72°C, below the operational limit of 90°C; on average, 30°C higher than the PVC plate that they’re attached to. This shows the importance of the thermal interface between the chip and the board.

In addition, the temperature over the rest of the components is quite homogeneous and kept within a reasonable range, i.e., lower than 26°C, which is safe for bare hands.

The CHT simulation evaluated the flow and heat pattern of the LED spotlight, taking into consideration design-specific and realistic material properties, geometry, and size. The analysis results helped to determine that the surface temperature of 72°C for the heating chips satisfied the operational limit of 90°C. This means the passive convection cooling strategy is sufficient, and the components can be guaranteed maximum lifetime operation.

Conclusion

By using numerical simulation, especially cloud-based solutions, the cost and time of each design iteration cycle is significantly reduced, ultimately creating cheaper and more competitive electronics.

References

1. “Consumer Electronics Report 2020,” Statista.

2. “What is the Growth Rate of the Electronics Sector?,” Investopedia.