Members can download this article in PDF format.

So how do you choose a microcontroller for a new design? Do you go to the MCU you’re familiar with and have been using for a while? Or do you opt for a company recommended chip? Or perhaps search for something appropriate to the application?

As many of you have experienced, it’s not an easy choice. With dozens of companies making MCUs in many variations, your alternatives are overwhelming. One approach is to start from scratch and write out a list of your needs, requirements, and specifications and try to match those up with available devices. Also, not easy.

One application space needing lots of attention today is the industrial IoT (IIoT), or Industry 4.0. This includes factory automation, industrial control, and anything with robots, motor control, and smart vehicles. Using those targets as examples, here are some of the various features, needs, and specifications that you might identify:

- Real-time control: So many manufacturing functions, especially robots, need real-time computing. Whatever it is, it must be fast and get done immediately. That calls for processor speed and/or perhaps multiple processors.

- Networking: Practically everything in smart factories, automobiles, or wherever is connected to something else, and networking is an inherent feature of the whole Industry 4.0 definition. Not only do you need conventional networking connections, but also special fieldbuses or the popular Ethernet-based links to sensors and actuators and other devices.

- Motor control: Industry applications always involve lots of motors—and different types of motors. A processor that can handle some of the more advanced motor-control algorithms is essential.

- Robots: Robots are everywhere. They require special handling. And usually, real-time control

- Edge computing: The trend is to do processing at the edge of the network or facility. That is, have local computers or servers perform the computing at the point of data collection. Analytics done at the edge rather than in the cloud is important to get the kind of performance you want.

- Low latency: This feature has become a key requirement in most new high-performance designs’ computing and networking. It’s what makes real-time possible.

These five categories essentially sum up your needs:

- High performance—may need up to a 10X performance boost over current designs.

- Real-time control a must in computing and networking.

- Power efficiency—reasonable power consumption despite the conflicting speed requirements.

- Design simplicity and reuse.

- Cost optimization.

Can your processor do that?

This MCU Can Do That

Texas Instruments recently announced a new version of its Sitara microcontrollers. Designated the AM243x line, these MCUs have the features described above. But how can they provide so much performance in a single chip? The answer: they integrate a significant amount of circuitry, including processors, memory, networking, I/O, accelerators, and security.

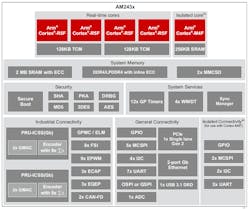

For instance, the three available models—the AM2431, AM2432, and AM2434—give you one, two, or four 32-bit Arm-Cortex-R5F cores running at speeds up to 800 MHz each. Multiple cores let you partition critical parts of your design so that real-time response can be obtained where needed.

To aid in those endeavors, the AM243x MCUs put lots of RAM rather than flash into each core to ensure the required speed of data access or instruction execution. All this can take place with less than 1 W of power consumption.

As for networking, they offer just what factory automation engineers need—industrial network standard connections. The new Sitara MCUs include Ethernet with backward compatibility to handle 10/100 versions. Optional support is provided for Profinet IRT, Profinet RT, EtherNet/IP, EtherCAT, IO-Link Master, and time-sensitive networking (TSN).

There are plenty of standard I/O ports to address your specific needs, including an Ethernet switch with support for RGMII 10/100/1000 plus Energy Efficient Ethernet, USB 2.0 and 3.1, six I2C ports, two UARTs, two CAN-FD, and seven SPI ports along with multiple GPIOs. Analog capability includes one multiplexed 12-bit, 4-Msample/s ADC and seven pulse-width-modulation (PWM) modules.

One essential accelerator focuses on safety and security. It covers all of the major common encryption and authentication protocols. These processors also meet the Safety Integrity Level (SIL) 3 specifications of the IEC 61508 standard.

In addition, the chip contains a power-management subsystem with overvoltage and undervoltage sensing, power on/sequence control, and other power-related functions.

Finally, these MCUs come in two sizes: a 17.2- × 17.2-mm, 441-pin FCBGA and an 11- × 11-mm, 293-pin FC/CSP.

For a summary of all the basic features, see the functional block diagram of the Sitara AM243x MCUs in the figure.

When working with sophisticated MCUs like the Sitara AM243x, strong software support is essential. That’s available in multiple forms. It starts with the LaunchPad Development Kit, which costs less than $100. Real-time control, networking, certified protocol stacks, networking solutions, and useful control algorithms are available as examples.