Members can download this article in PDF format.

What you'll learn:

- The differences between physical and data-link layers in Ethernet.

- Key factors in selecting an industrial PHY.

As digitalization progresses further in nearly all aspects of our daily lives, ever greater volumes of data need to be exchanged constantly between different devices and machines. Especially in industry, conventional communications technologies are running up against their limits, and Ethernet, or in this case industrial Ethernet, is emerging as the new standard. With it, very high data rates in the gigabit range can be achieved over distances of up to 100 m, or even several kilometers when using fiber-optic cables.

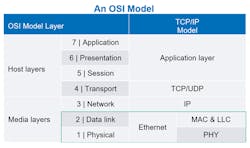

Ethernet is an interface specification set forth in IEEE 802.3. One of the elements of IEEE 802.3 is the Ethernet physical layer (PHY). It’s a transceiver component for transmitting and receiving data or Ethernet frames. In the OSI model, Ethernet covers Layer 1 (physical layer) and part of Layer 2 (data-link layer).

Physical and Data-Link Layers

The physical layer specifies the types of electrical signals, signaling rates, media and connector types, and network topologies. The Ethernet PHY can be mapped onto it (see table).

The PHY forms the physical interface and is responsible for coding and decoding of data between a purely digital system and the medium transmitting the signals. It thus represents a bridge between the digital and electrical connection levels of the interface.

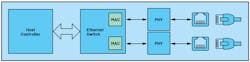

The data-link layer defines the way in which communication takes place over the medium and the frame structure for the transmitted and received messages. This means it defines how the bits from the wire are arranged to enable extraction of the data from the bit stream. With Ethernet, this is called media access control (MAC) and is found in the immediate vicinity of the PHY, but in the data-link layer. The MACs are usually integrated into controllers or switches.

PHYs can be discrete components or be integrated into Ethernet controllers. A simplified block diagram showing the required Ethernet components and discrete PHYs can be seen in the figure.

If a design needs to be realized using discrete PHYs, a PHY should be selected with a few criteria in mind.

Important Criteria to Consider when Selecting an Industrial PHY

In industrial applications, the data transmission and the network must be highly reliable and fail-safe over a wide range of temperatures. This applies accordingly to all components.

Network Cycle Times

The network cycle time is the time it takes for the controller to collect and update the data from the connected devices. A PHY with a low latency shortens the network cycle time and thereby improves the network update time, which is especially important for time-critical applications. As a result, more devices can be connected to the network.

Susceptibility to Interference/Robustness

Operating environments in industrial applications are often harsh. A PHY must be able to withstand the prevailing external conditions because it’s connected directly or via small magnetics to the cables, into which interference (radiated or conducted) can be coupled.

EMC standards such as CISPR 32 and IEC 61000-4-2 to IEC 6100-4-6 are yardsticks against which a PHY specification should be measured. Robust PHYs pave the way for certification and eliminate the usually tedious task of redesign.

Losses and Temperature Range

Devices for industrial applications are usually protected against dust and moisture ingress to IP65/IP66. This restricts the airflow available for cooling the electronics. At the same time, devices in industrial applications are often exposed to high ambient temperatures.

In addition, for line and ring topologies, two Ethernet connections and thus two PHYs are required, which doubles the PHY losses for data input and output. Therefore, PHYs with low losses should be selected to minimize self-heating.

ADI External PHYs

Analog Devices developed its industrial Ethernet PHYs with focus on industrial requirements. To supplement its Chronous industrial Ethernet family, the company introduced the ADIN1200 (10/100 Mb/s), ADIN1300 (10/100 Mb/s; 1 Gb/s), and ADIN1100 (10BASE-T1L).