Download this article in PDF format.

Being healthy and productive at home, on the factory floor, at the office—or even at the beach—requires being in a comfortable environment. That certainly includes a comfortable temperature, but the job of the environmental designer goes far beyond just controlling the thermometer setting.

Take comfort level, for example. It’s a subjective feeling that depends not only on the temperature, but also the humidity level. At a given temperature, workers suffer adverse consequences as the humidity rises, so temperature and humidity are often combined to form a “heat index” that can bring significant health risks at high levels. Before the danger zone arrives, changes in temperature or humidity can quickly result in an environment that feels uncomfortable to a typical individual—a subjective “comfort zone.”

Significant excursions outside the comfort zone can affect health. However, even small changes may impact work performance, which degrades if the effective temperature strays outside of a relatively narrow band.

Sponsored Resources:

- Renesas/IDT Air Quality Sensor reference design with RL78/G14 Microcontroller

- HVAC Air Quality Sensor Renesas/IDT Air Quality Sensor reference design with ZMOD4410 Gas Sensor

- Renesas/IDT Air Quality Sensor reference design with HS300x Humidity Sensors

Temperature and humidity are by no means the only environmental factors that affect health and wellness. Air quality also plays a crucial role, particularly the concentration of chemicals included in the category of “volatile organic compounds” (VOCs). VOCs comprise thousands of natural or man-made organic chemicals that are mostly gases at room temperature, although the category excludes some well-known gases such as carbon monoxide (CO) and carbon dioxide (CO2).

The sources of VOC vary by location. In the home, there are detergents or perfumes in the bathroom; furniture or carpets in the living room; and automotive fluids or pesticides in the garage (Fig. 1). On the street, there are automobile emissions. And factories include a wide range of chemicals. The total VOC (TVOC) combines the different VOCs into a single measure.

1. Good indoor air quality is an important factor in maintaining a healthy home or work environment. (Source: IDT)

Significant health hazards are associated with poor air quality. The nightly news warns at-risk populations to stay indoors during periodic pollution advisories, but indoor air contaminants in residential and office spaces are also a serious issue. The U.S. Environmental Protection Agency (EPA) estimates that poor indoor air quality (IAQ) affects 33% to 50% of commercial buildings in the U.S. and is responsible for over 125 million lost school days and 10 million lost workdays each year.

Semiconductor Technology to the Rescue

To help alleviate the problem, heating, ventilation, and air-conditioning (HVAC) systems in large buildings increasingly include air-quality measurement as part of their design.

Semiconductor technology helps by enabling the design of accurate and low-cost sensors that measure temperature, humidity, and IAQ. Applications for these sensors include home, workplace, and automotive climate-control systems. They’re also found in home appliances, weather stations, industrial automation, and medical equipment.

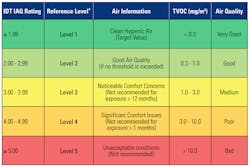

As shown in Figure 2, IDT sensors rely on guidelines from the German Federal Environment Agency UBA.

2. IDT sensors are calibrated based on IAQ work performed by UBA, the German Federal Environment Agency. (Source: IDT)

MEMS Technology Helps Improve Health and Wellness

Sensors for environmental monitoring rely on a range of semiconductor technologies. Microelectromechanical-systems (MEMS) sensors, for example, use semiconductor fabrication techniques to produce miniaturized mechanical and electromechanical elements that can range from simple structures with no moving parts to complex electromechanical systems with multiple elements. MEMS-based sensors are highly sensitive, extremely accurate, and have excellent repeatability. They’re used to measure acceleration, rotation, pressure, and many other attributes because they’re much smaller, cost less, and consume less power than alternative technologies.

Environmental monitoring utilizes MEMS technology to measure relative humidity. A MEMS humidity sensor consists of a layer sensitive to water vapor; this is sandwiched between two electrodes that act as capacitor plates. The upper electrode is a grid that allows water vapor to pass into the sensitive layer, changing its dielectric value and altering the capacitance between the two electrodes.

The relative humidity (RH) for a given value of measured water-vapor density varies with temperature. Thus, a MEMS relative humidity sensor usually incorporates two sensing elements: one to measure humidity and another to measure temperature. An on-chip circuit or an external MCU carries out automatic calibration and signal processing to produce an RH measurement.

Measuring Indoor Air Quality with a Chemiresistive Sensor

Many VOC measurement techniques have been developed over several decades. Examples include thermal-conductivity detectors (TCDs), gas chromatography (GC) detectors, non-dispersive infrared (NDIR) sensors, and many others. These techniques have their advantages and disadvantages in different applications, but VOC measurement for IAQ monitoring has spurred a demand for inexpensive, miniaturized, portable, and highly sensitive sensors.

Current-generation IAQ sensors typically use a chemiresistor—a semiconductor material that varies its resistance in response to changes in the surrounding chemical environment. A chemiresistor works through adsorption and desorption, which are surface processes that involve the accumulation or release of gas molecules. Adsorption and desorption vary the free charge carrier concentration in the material, causing the change in resistance.

Both p- and n-type semiconductors can exhibit chemiresistance. Many of these are metal oxides (MOx), such as zinc oxide (ZnO), tin oxide (SnO2), indium oxide (In2O3), tungsten trioxide (WO3), copper oxide (CuO), and nickel oxide (NiO).

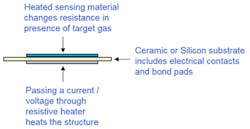

A MOx sensor makes use a thin-film metal-oxide layer to measure air quality; the sensor outputs an analog signal that indicates the concentration of the target gases. This signal is then converted into a digital equivalent in which specific gases are quantified. The adsorption process requires high temperatures, so the MOx sensor is packaged with a heating element as shown in Figure 3.

3. A MOx sensor integrates the sense element and a resistive heater on a single substrate. (Source: IDT)

A MOx sensor offers affordable, reliable performance in harsh applications. However, each MOx solution has many integral aspects that support optimized performance. The substrate used, the applications circuitry, and the MOx material are all critical components of the sensor design.

System Components for Air-Quality Monitoring Applications

Integrated Device Technology (IDT), now a Renesas company, offers several sensor modules and reference designs that utilize the technologies discussed above to simplify the task of monitoring temperature, humidity, and IAQ.

The HS3001, for example, is a highly accurate, fully calibrated RH and temperature MEMS-based sensor that features a proprietary sensor-level protection, ensuring high reliability and long-term stability. The HS3001 is a member of the HS300x family that consists of four parts with a range of accuracy specifications.

The HS300x family features a ±1.5% RH accuracy and a six-second response time to a stable measurement. Since humidity sensors consume the most power while measuring, the fast response time reduces the amount of sampling needed. That’s a key advantage in battery-powered applications, where lower power consumption results in longer battery life. The HS300x family features excellent long-term stability of 0.1% RH per year; this improves useful lifetime and lowers its effective cost.

The HS300x includes calibration and temperature-compensation logic to provide fully corrected RH and temperature values, so no calibration of the output data is required. After performing a measurement, the HS300x transmits four bytes over its I2C interface: a slave address, 14 bits of humidity data, 14 bits of temperature data, plus status bits that indicate the state of the fetched data.

A system microcontroller (MCU) can then calculate the relative humidity in percent and temperature in degrees Celsius with two simple equations:

The high-accuracy fast measurement response time, long-term stability, and small package size makes the HS300x series well-suited for a large number of environmental monitoring applications.

ZMOD4410 Monitors IAQ

The ZMOD4410 Gas Sensor Module is designed to detect and measure typical TVOC contaminations in consumer and industrial IAQ applications. They include monitoring of home or office indoor air quality; detection of hazardous materials to avoid unhealthy conditions (e.g., fumes from construction materials); and automated control of HVAC systems, air purification systems, or thermostats based on IAQ levels.

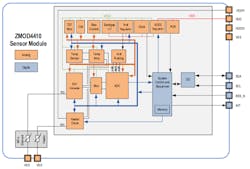

The module (Fig. 4) includes a gas sense element and a CMOS signal-conditioning IC, housed in a 12-pin LGA assembly measuring 3.0 x 3.0 x 0.7 mm. The gas sense element consists of a MOx chemiresistor and a heater element on a Si MEMS structure. The signal-conditioning IC controls the sensor temperature and measures the MOx conductivity, which is a function of the gas concentration.

4. The ZMOD4410 gas sensor module includes digital, analog, and sense elements. (Source: IDT)

The ZMOD4110 outputs the measurement results via I2C to an external MCU that processes the data to calculate the TVOC concentration and IAQ rating. IDT offers a downloadable firmware library with application-specific configurations for thermostats, building controls, HVAC equipment, smart fans, air purifiers, and more.

IDT also developed a patent-pending correlation between elevated VOC levels and CO2 due to human occupancy. This correlation allows the prediction of an estimated carbon dioxide (eCO2) level.

Detection of safety-relevant gases such as carbon monoxide (CO) is also possible with the ZMOD4410, although the device isn’t designed for this purpose, nor is it approved for use in safety-critical applications.

The ZMOD4410 software can generate a control signal based on IAQ levels. A typical application might be to remove undesired odors by turning on an external device such as a fan.

Moreover, the ZMOD4420 features a Low-Power Operation Mode with a fixed sampling interval of 6 seconds. In this mode, the ZMOD4410 consumes only 1 mW, making it an excellent choice for low-voltage and low-power battery applications. Built-in nonvolatile memory (NVM) stores the configuration settings and provides space for arbitrary user data. Further information on the various operating modes is available in the datasheet.

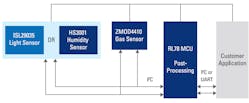

Renesas Reference Design for Environmental Monitoring

The sensors discussed above come together in a reference design (Fig. 5) that combines the ZMOD4410 gas sensor, the HS300x humidity sensor, and Renesas' RL78/G14 series MCU. It ultimately forms a complete environmental monitoring solution for HVAC systems, smart appliances, smart home, and smart office applications.

5. An environmental monitoring design with components from IDT and Renesas. (Source: IDT)

The RL78/G14 MCU processes data from the HS3001 and the ZMOD4110. The MCU is built on a 16-bit CISC CPU core. It features a combination of high performance and ultra-low power consumption with up to 51.2 Dhrystone MIPS per MHz (DMIPS/MHz). The complete RL78 family includes over 1000 devices that offer scalability and reusable software code for a broad range of applications.

Conclusion

Environmental monitoring requires the measurement of several parameters such as temperature, relative humidity, and IAQ. Semiconductor technology allows the construction of inexpensive sensors that blend high performance with low power consumption.

Renesas and IDT offer a portfolio of sensors and reference designs that simplify the design of environmental monitoring systems for numerous applications in homes, factories, and offices. All of the components discussed are available from Digi-Key, as well as multiple power and timing solutions to help complete the design.

Sponsored Resources:

- Renesas/IDT Air Quality Sensor reference design with RL78/G14 Microcontroller

- HVAC Air Quality Sensor Renesas/IDT Air Quality Sensor reference design with ZMOD4410 Gas Sensor

- Renesas/IDT Air Quality Sensor reference design with HS300x Humidity Sensors

Related References: