Download this article in PDF format.

When you think of a sensor, you probably don’t think of millimeter-wave (mmWave) radar. Now, though, you can add mmWave radar chips to your mental archive along with the other more traditional sensors. If you’re designing new systems requiring proximity detection and the presence and movement of people, these radar ICs just may be a solution to consider.

Sponsored Resources:

- Factory Safety Guards using mmWave

- Smarter Robotics through mmWave Radar Sensing

- 60GHz mmWave white paper

Radar on a Chip: More Uses Than You Think

Actually, radar chips have been available for years. Their primary application has been in automotive advanced driver-assistance systems (ADAS) to detect nearby vehicles and persons, automate adaptive cruise controls, and implement automatic braking for collision avoidance. Traffic monitoring at intersections and other locations is a growing transportation application.

Other uses involve industrial applications. One example is liquid-level measurement in tanks that are part of a process control system. And new approaches continue to be explored and applied, such as people detection, counting, and movement monitoring.

A major new use-case is safety guards in factories. Factories are becoming smarter as man and machine work “hand in hand.” To reduce the possibility of a robot colliding with a person, some proximity and position sensing is needed. Collisions with mobile robots and forklifts can be avoided by deploying radar sensors.

Industrial mmWave sensors can be used for any high-accuracy occupancy detection and collision avoidance—the position and velocity of people would trigger systems when a person or an object is in proximity of a machine. Accuracy with good resolution is essential for the success of such protective systems.

Other uses include building automation, where radars are used for people detection, movement, and counting. They’re actually able to see through dry wall, for example. With this occupancy information, the building HVAC can be appropriately applied and regulated, leading to significant energy savings. In home applications, radar chips make good surveillance and perimeter security devices.

Radar IC Features and Specifications.

The first IC radars operated at 24 GHz. Both narrowband and ultra-wideband versions were available. Last year, the Federal Communications Commission (FCC) and the European Telecommunications Standards Institute (ETSI) passed rules prohibiting the use of 24-GHz wideband devices. The ultra-sideband will no longer be available after January 1, 2022.

The rulings are probably related to the assignment of 24-GHz spectrum to the forthcoming 5G wireless systems. This should reduce interference to the large number of 5G devices expected to arrive. In any case, the loss of a wideband option greatly restricts the radar’s range and resolution. Luckily, other radar spectrum is available. Specifically, single-chip radars are available for the mmWave frequencies of 60, 77, and 79-81 GHz.

The radar chips work like all radars in that they transmit a signal and then receive its reflection. Single-chip radars usually have two or three transmitters incorporating frequency-modulated continuous wave (FMCW) that send out a continuously increasing 4-GHz-wide frequency signal called a chirp. Four receivers pick up the reflection from the remote object. Then, using the time and frequency changes measured, the chip can determine range and speed. With directional antennas, the angle to the object detected also is discernable. Maximum typical range is 10 meters, but range resolution is 4 cm. The total field of view can be as wide as 120 degrees with a 15-degree angular resolution. Movement velocity potential peaks at 0.6 meters/s.

Real Products

Three single-chip radars developed by Texas Instruments—the IWR6843, IWR1642, and IWR1443—are made with a 45-nm RFCMOS process. They’re packaged in a 10.2- × 10.2-mm flip-chip ball-grid array (BGA).

The IWR6843 operates in the 60- to 64-GHz range, while the IWR1642 and IWR1443 use the 76- to 81-GHz frequency range. The main difference between the IWR1642 and the IWR1443 are that the former has only two transmitters and a different mix of I/O interfaces. The IWR1443 features three transmitters plus a radar hardware accelerator to assist the digital signal processor (DSP) in handling the complex algorithms used for detection. In addition to the analog radar system, these chips include two processors: an Arm Cortex-R4F and a TI C674x DSP. Both are programmable to fit the application.

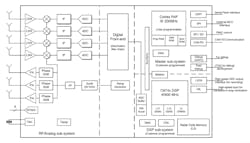

The figure shows the main components of the IWR6843 60-GHz radar transceiver. While the 77-GHz band is dedicated mainly to automotive applications, 60 GHz is a good choice for industrial safety applications

The 60-GHz IWR6843 single-chip radar is well-suited for factory safety applications.

A key feature of these new devices is that the antennas are small enough to fit on the printed circuit board. At 60 GHz, a half wavelength is only about 5 mm and about 4 mm at 77 GHz. This makes arrays of dipole or patch antennas very small. Such arrays (4 × 4, 8 × 8, etc.) can form narrow beams that improve accuracy and resolution of detection as well as boost power levels.

In Summary

TI’s radar ICs can be used in a wide range of applications, particularly in the all-important area of factory safety. The mmWave sensors enable intelligent object detection by integrating accurate sensing with real-time decision-making and processing on a single chip. This is expected to help further accelerate the adoption of robotic systems. Such sensors can be used for high-accuracy occupancy detection and collision avoidance, too, where the position and velocity of people can be used to trigger systems when a person or an object is in proximity of a machine.

Sponsored Resources: