Printed-circuit-board (PCB) services are typically how developers start building prototypes and how small-to-medium production runs are done, since investing and managing an in-house PCB isn’t always warranted. A large number of services are available, including those from Elecrow.

I talked to Jarvan Hu, Sales and Marketing Manager at Elecrow, about what developers should look for when farming out PCB chores, as well as what’s provided by Elecrow. Most vendors can generate basic 2-, 3- and 4-layer board,s but there are many more options than just these including flexible circuits.

Jarvan Hu, Sales and Marketing Manager, Elecrow

What should developers check for when looking for a PCB service?

When I was asked this question, I was thinking that you may be not an experienced PCB designer, and probably you just have a small quantity of boards to be printed. From my point of view, developers should really check for certain items when looking for a PCB service provider.

For instance, does the PCB supplier support online custom PCB services? It’s important to place your order directly on-line, it’s really convenient, and can save you a lot of time.

Does the PCB supplier offer an inexpensive, small number minimum order quantity (MOQ) and short lead time? You usually don’t have volume demands for PCB services from students or electronics hobbyists. Sometimes, when your order is small, the supplier won’t pay attention to your requirement. So, when you’re measuring the supplier’s qualification, you’d better carefully check to see if bare PCB manufacturing lead time is no more than one week regularly; the MOQ can be as small as five pieces; and the price for five PCBs can be as low as $4.90.

Does the PCB supplier have a good track record? It’s necessary to make sure the supplier you’re going to work with has positive comments from the customers. You can find this information on PCB forums or in-site reviews.

Do your files meet the supplier’s requirements? Some new developers are likely to make simple errors if they don’t pay much attention to the requirements of the manufacturer at the beginning, which may lead to bad boards or waste of time. So I suggest to check this link to view the common mistakes that you should avoid before you place the PCB order to a supplier.

How hard is it to work with flexible PCB solutions?

Differing from the inflexible rigid PCB, we all know that flexible PCB can be bent, shaped, and folded to various dimensional structures. And, due to the features of high wiring density and thin thickness, it enables electronic designers to realize the dimensional flexibility in their creativity for electronic wiring systems. However, in my opinion, the difference in dimensional property also brings about three major challenges when developing flexible PCB solutions.

For one, there are challenges in designing flexible PCBs. To ensure that solder joints won’t break when bending PCBs, the flexible circuits need to have radiused corners and filleted pads (Fig. 1), which is quite different from the sharp corners and acute junctures in the design of rigid PCBs. Another issue in design is the lack of design software for flexible PCBs; most software uses the design rules for rigid PCBs. So, tradeoffs or compromises occur when using the same software to do flexible PCB design.

1. Elecrow’s Flex PCB made for a button.

Second, challenges crop up in the fabrication of flexible PCBs. Even though the manufacturing process of flexible PCBs is quite similar to that of the rigid PCB, the difference between the flexible substrate and the rigid board also makes the handling system of flexible PCBs more complex. Handling a thin, flexible circuit may need special clamping, fixturing, or even vacuum systems to fix it in place. Some high-volume flexible PCB manufacturers must operate circuits in continuous reel-to-reel processing, which uses significantly different materials-handling mechanisms than systems processing discrete panel sizes.

Lastly, there are challenges regarding flexible PCB materials. Flexible PCBs require relatively special dielectric materials, such as laminated coverlay, which has unique properties and challenges. For instance, some applications require millions of cycles, so the material has to be able to withstand repeated bends and flexes and not sustain any cracks or breaks. Thus, some features need to be considered in the design for dynamic flexible applications, including circuit pattern layout, copper grain direction, trace geometries, and coverlay thickness. Laminated coverlay is the most common flexible dielectric. It could be bonded to the flexible substrate in high-temperature and high-pressure conditions—a solution that’s hardly ever used for rigid PCBs.

Does Elecrow provide flexible PCB solutions for customers?

Elecrow is able to provide affordable flexible PCB solutions. When customers contact us about flex PCBs or rigid-flex PCBs, we have engineers available for any technical questions or requirements. They can seamlessly work with our dedicated flex PCB production group to create flexible PCBs using a variety of technologies (from single-sided flex PCB to complex multilayer flexible PCB). The whole process is organized and going very well, so our lead time for flex PCB is now as short as one week. As shown in Figure 2, we have separated production groups handling flex PCB projects from other projects.

2. The Flex PCB project and other PCB projects are separated into different production groups.

What types of services does Elecrow offer?

We devote ourselves to open-source hardware, offering PCB prototyping, PCB assembly service, and thousands of DIY electronics such as Arduino- and Raspberry Pi-related products, robotics platforms, and other electronic materials.

Elecrow’s PCB prototyping is very popular among electronic engineers. We support instant online PCB quotes and ordering to simply the process for customers. The price and quality is fairly well received; you can see lots of positive comments about our PCB service in our customer review page. Also, in the PCB price comparison website “pcbshopper.com,” Elecrow is the top-rated supplier among worldwide PCB manufacturers.

Elecrow’s PCB assembly is spoken highly of among startups and individual hardware creators. We helped to produce several kickstarter projects; some of tindie sellers are having their boards assembled in our PCB house. Elecrow PCB assembly service is flexible. We can help you with orders as small as one-piece sample boards, and/or bring your batch order into market with high quality and short lead time.

3. Elecrow’s Starter kit for Raspberry Pi has several parts, including a clear 9 Layers protection case box that’s compatible with Raspberry Pi B+/2B/3B.

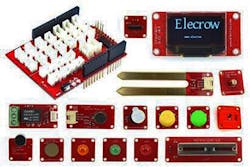

As for Elecrow’s DIY electronics, it can be dispatched to electronics enthusiasts worldwide. We develop our own Crowtail products to help makers learn about electronics and carry out simple experiments. Elecrow also provides Arduino- and Raspberry Pi-related products. The Raspberry Pi monitor is extremely popular in our store, and other starter Raspberry Pi or Arduino learning kits are also welcomed by beginners (Figs. 3 and 4).

4. The Crowtail Starter Kit, which consists of a Base Shield and some basic Crowtail modules, helps Arduino beginners learn basic usage and Arduino programming on a step-by-step basis.

How would you describe your products and services?

Make Your Making Easier! This is our slogan. We print it out and take it everywhere we travel. This is what excites us at Elecrow, and what we promise to every customer all around the world. We are a young and spirited team (Fig. 5)!

5. Here’s the Elecrow team during some outdoor training.

With over four years of experience in oversea sales and marketing, Jarvan Hu, Sales & Marketing Manager, has been engaged in electronic industry for over three years. As the marketing manager for Elecrow, he is mainly responsible for marketing research and analytics; brand building and market promotion; product development; and external cooperation on Arduino, Raspberry Pi, and PCB assembly.