Spurred by advances in electric vehicles (EVs) and autonomous driving, the number of electrical components in automotive design continues to climb. And each of these applications requires a variety of voltage sources, all of them stabilized by capacitors. This results in greater demand for external components, larger PCB sizes, and additional bill-of-materials (BOM) costs.

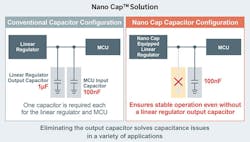

In a circuit comprised of a linear regulator and MCU, a 1-µF capacitor is usually required at the output of the linear regulator, while 100 nF is requested at the input of the MCU. However, according to Rohm, its new Nano Cap technology ensures stable control of power-supply circuits in automotive applications with nanofarad (nF, or 10-9F) capacitances.

Leveraging Rohm's linear regulator utilizing Nano Cap technology—developed by combining analog circuit design, layout, and process development—eliminates the need for the capacitor at the regulator output and ensures stable operation with just a 100-nF input capacitor. Decreasing both the number of capacitors along with the capacitance needed for power-supply circuits in the automotive (and other) fields minimizes circuit design load.

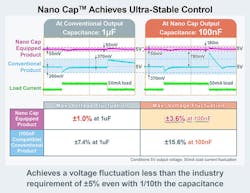

Nano Cap provides stable control of linear-regulator output by improving response in analog circuits while minimizing parasitic factors related to wiring and amplifiers. As a result, it reduces the output capacitance to less than 1/10th that of conventional solutions, says Rohm.

Thus, circuits composed of a linear regulator and MCU, which usually require a 1-µF capacitor at the output of the linear regulator and a 100 nF at the input of the MCU as mentioned above, Nano Cap linear regulator technology achieves stable operation using just one 100-nF capacitor at the MCU side.

Given industry requirement for output-voltage fluctuation of ±5.0% max, Nano Cap-equipped chips achieved a stable operation of ±3.6% in test evaluation. Conventional linear regulators’ output voltage can vary by as much as ±15.6%.

Nano Cap joins other Nano power-supply IC technologies previously introduced by Rohm, including:

Nano Pulse Control

Rohm’s high-speed pulse-control technology for power-supply ICs achieves a switching ON time (control width of the power-supply IC) on the order of nanoseconds (ns), making it possible to convert from high to low voltages using a single IC. Conventional solutions typically require two or more power-supply ICs. This contributes to greater miniaturization and system simplification in 48-V applications ranging from mild hybrid vehicles and industrial robots to base-station power supplies.

Nano Energy

This low-current technology features a no-load current consumption in the nanoampere range by minimizing the tradeoff that occurs when reducing current consumption at ultra-light loads. As a result, the 10-year drive on a single coin battery demanded by the IoT market is possible, supporting long-term operation in compact battery-driven applications, including portable devices, wearables, and the IoT.

Rohm said it’s committed to further enhancing the development of Nano Cap technology to completely eliminate the need for capacitors while expanding the use of this technology not only to linear regulators, but op amps, LED drivers, and other analog ICs as well. Op-amp samples utilizing Nano Cap technology have already been released in part, and linear regulators utilizing Nano Cap technology as well as LED drivers with built-in Nano Cap-equipped regulators are scheduled to be released this year.