The global trend toward vehicle electrification has put renewed attention on the design of cost-effective traction inverters, which convert energy from the vehicle's battery to drive the motors in the drivetrain. This key component has a direct impact on road performance, driving range, and reliability of the vehicle. In this context, selecting the power module plays an important role—system designers are looking for the best-sized module with optimal silicon area for the required performance.

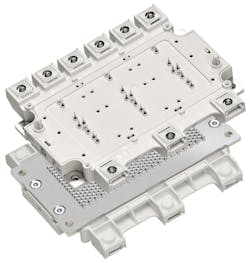

To meet this need, Infineon Technologies introduced a power module in the 80- to 100-kW power class: the HybridPACK DC6i. This six-pack module, aimed at hybrid and small battery electric vehicles, combines the company’s EDT2 IGBTs with package technologies for compactness, good thermal management at reduced material cost, and easy installation.

Within Infineon’s portfolio, the HybridPACK DC6i is positioned between the HybridPACK1 family and the more powerful HybridPACK Drive family. The new module has the same footprint (7.2 × 14 cm) as the HybridPACK1—25% smaller than the HybridPACK Drive—but the available output power is more than 50% higher.

While the HybridPACK1 uses Infineon’s IGBT3 technology, the HybridPACK DC6i is equipped with the company’s EDT2 IGBTs, an automotive Micro-Pattern Trench-Field-Stop cell design optimized for electric drivetrain applications. It offers a blocking voltage of 750 V, a short-term extended operation temperature of 175°C, and short-circuit ruggedness. The design tradeoff between switching and conduction losses is optimized for a real-world driving cycle with excellent light-load power losses, according to Infineon, leading to an efficiency improvement of 20% compared to its previous IGBT3 generation.

Infineon further notes that the HybridPACK DC6i’s current density combined with its ruggedness and increased blocking voltage yields reliable inverter operation under harsh environmental conditions. The chipset is optimized for switching frequencies in the range of 10 kHz.

The new module has six screw connectors to the DC-link capacitor compared to two in the HybridPACK1 family. This enables a low-inductive design with a stray inductance said to be 15 nH.

Fluid Cooling

Infineon also claims the HybrickPACK DC6i optimizes costs for fluid cooling with a ribbon-bond baseplate. Like most high-power automotive IGBT modules, it’s direct fluid cooled. Infineon’s patented direct-cooling wave baseplate provides cost-effective heat dissipation, with a thermal resistance from the IGBT chip junction to the fluid of 0.17 K/W. The baseplate is made of copper (Cu) material with nickel (Ni) plating.

For power modules with direct fluid cooling, the recommended mixture of the cooling fluid type is specified to be 50% water/50% ethylene glycol. The fluid mixture has to provide enough anti-freeze for the application conditions. Freezing fluid will lead to plastic deformation of the power-module baseplate and may lead to fluid leakage and/or isolation failure. It’s also important to ensure that the fluid type with its corrosion protection is compatible with the material of the plate (in this case, copper with nickel plating).

The DC6i was designed with high-volume production in mind: PressFIT pins and additional mechanical guiding elements enable gate-driver board mounting in a few seconds compared to traditional selective soldering, which requires more than one minute. PressFIT technology offers the possibility of reliable, solderless mounting of power modules, meeting the demands of lead-free technology.

Low electrical and thermal contact resistance makes the contact suitable for a wide range of currents and applications. Infineon said environmental tests show that vibration loads and climate sequences have no negative influence on the contact resistance, which is a result of the gas-tight contact and high contact force. The high holding forces of the contact are independent of the PCB hole tolerances. This also reduces the effort needed for mechanical fixing.

The HybridPACK DC6i is fully qualified according to the AQG324 standard for automotive power modules. AQG324 is the “European Qualification Guideline for Power Modules for Use in Power Electronics Converter Units in Motor Vehicles.” Based on the former German LV 324 (“Qualification of Power Electronics Modules for Use in Motor Vehicle Components - General Requirements, Test Conditions and Tests”), the EC guideline defines a common procedure for characterizing module testing as well as for environmental and lifetime testing of power electronic modules for automotive applications.

The present AQG324 version (April 12, 2018) focuses on silicon-based power modules, where future versions to be released will also cover the new wide-bandgap silicon-carbide (SiC) and gallium-nitride (GaN) power semiconductors.

The new HybridPACK DC6i is in production and will be available at distributors in September 2020.