There’s apparently little limit to the imaginative ways to explore and exploit the “something for almost nothing” potential of energy harvesting. Researchers at UCLA working with participants at other institutions devised a triboelectric-based energy harvester that creates electricity from falling snow. Their snow-based triboelectric nanogenerator (TENG) uses the fact that falling snow is positively charged and seeks to give up electrons (Fig. 1).

Co-author Maher El-Kady, a UCLA assistant researcher of chemistry and biochemistry, said “Snow is already charged, so we thought, why not bring another material with the opposite charge and extract the charge to create electricity?”

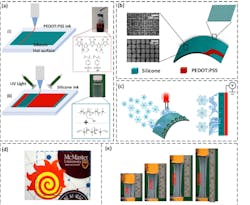

To pair with the falling snow and create the required electron transfer, they needed a suitable negatively charged material. “After testing a large number of materials including aluminum foils and Teflon, we found that silicone produces more charge than any other material,” said El-Kady. They then used 3D printing to construct the device, which has a layer of silicone and an electrode (Fig. 2). This allowed them to precisely control the design and deposition of the electrode and triboelectric layer, leading to a flexible, stretchable, and metal-free TENG.

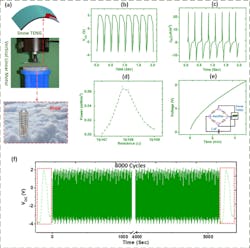

Based on the single electrode mode, the device can generate an instantaneous output power density as high as 0.2 mW/m2 (50-MΩ load), open-circuit voltage up to 8 V, and a current density of 40 μA/m2 under defined conditions (Figs. 3 and 4).

The team did more than merely build an energy-harvesting transducer and power source. The snow-TENG can function as a self-powered sensor and weather station to monitor the weather in real time to provide accurate information about the snowfall rate, snow accumulation depth, wind direction, and speed in snowy and/or icy environments. In addition, it can be used as a wearable power source and biomechanical sensor to detect human body motions.

The team believes the device could be produced at low cost given “the ease of fabrication and the availability of silicone,” added the project leader Richard Kaner, professor of chemistry and biochemistry, as well as materials science and engineering, and who holds UCLA’s Dr. Myung Ki Hong Endowed Chair in Materials Innovation.

Full details of theory, fabrication, and test are in their paper “All printable snow-based triboelectric nanogenerator” published in Elsevier’s Nano Energy.