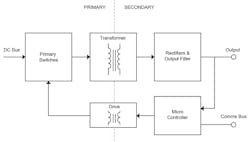

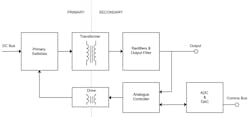

Digital control in power supplies can mean different things ranging from simple digital signaling of status/alarms and on/off control of a traditional analog controller (Fig. 1), to more sophisticated functions being added with a simple microcontroller, all the way through to full implementation of feedback-loop compensation with a digital signal processor (DSP) (Fig. 2). The latest techniques allow for flexibility in configuring a power supply’s characteristics and performance during development and commissioning, and dynamically in the end application.

Although a DSP chip costs more than a dedicated analog controller, prices are dropping and performance is improving, so the benefits become increasingly compelling. This is especially true at higher power with higher-value products, where the system’s performance boost is more evident and component cost is less of an issue.

DSP in a power-supply design does require knowledge of control-loop stabilization in the frequency domain and its implementation in efficient code in the time domain. However, the techniques are understood, and mainstream power-supply manufacturers are embracing the technology.

Investment is required, though, in skills and time to develop, verify, and document firmware to achieve a reliable and robust solution. Still, the code is reusable and common hardware platforms can be designed that could be quickly software-configured for multiple applications—a real benefit in production that’s then passed on to users in time-to-market and unit cost economies.

Digital Signal Processing: The Features and Benefits

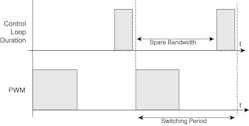

The main advantages of a fully digital implementation of power-supply control and monitoring are flexibility and ability to adjust performance and characteristics for different applications—something that would require hardware changes with a traditional analog controller. Digital control loops (Fig. 3) also have the advantage of being immune to environmental changes and variation of component values with tolerance and age. This enables more exact definition of performance.

Furthermore, the DSP chip can respond to system performance variables. Examples include detecting load characteristics and optimizing the control loop for best load transient response or dynamically lowering output voltage to reduce load power dissipation in standby modes.

Adjustment of output voltage can be extended to a wide range, even 0 to 105/110% for more general applications or when the final optimum system voltage simply isn’t known. Current limit is similarly adjustable, not just in “knee” value, but also for its characteristic in an overload or short circuit, perhaps “constant current” latch-off or “hiccup” mode. This is important in modern high-efficiency resonant topologies where the multiple switching and loop-compensation schemes required are impractically complex to achieve with a traditional analog controller.

Apart from controlling the feedback loop, in a digital power supply, it’s easy to include a host of other programmable features with system benefits that would entail hardware changes in analog implementations. For example, startup/shutdown ramp rate and sequencing of multiple supplies is settable with different schemes such as “ratiometric” or simultaneous; polarity of enable inputs and signal outputs can be toggled at will.

Fault and status conditions can be monitored and signaled, such as input undervoltage, output under/overvoltage, output overcurrent and overtemperature. All thresholds can be adjusted, dynamically if necessary. For example, if output voltage is adjusted higher “on-the-fly,” the overvoltage detection threshold can also be adjusted higher.

In addition, the response to warnings can be programmed with variable delays before signaling and the resulting action varied. Perhaps it would involve just logging of the occurrence or shutdown with a specified number of retries at specified intervals, or immediate latch-off for more serious events such as a sustained output overvoltage. Non-volatile memory in DSP chips can be utilized not just for the control algorithm and as lookup tables for response characteristics, but also to record other information such as model and build standard, serial number, run time, and an event log of temperature records and faults/warnings.

The latest microcontrollers with DSP functionality allow for this degree of functionality because they’re fast enough to sample output voltage every switching cycle, perform analog-to-digital conversion within a few hundred nanoseconds, execute the feedback control algorithm, and still have plenty of bandwidth for slower speed control and signaling. For flexibility and backwards compatibility, a built-in analog-to-digital converter (ADC) can also provide for analog control inputs such as 0 to 5 V or 0 to 10 V for voltage setting.

Furthermore, individual controls and signals are typically available on connector pins as well as through the communications bus. The bus might be accessible externally for system control or just internally to the power supply for service engineer use.

Digital Power in the Wider World

Power supplies with digital control and signaling come into their own in “smart factory” applications. It’s where process hardware is interconnected in an IoT configuration to maximize production capacity and efficiency on-the-fly.

A combination of intelligence at “the edge” and central monitoring and overall control not only adjusts parameters in real time for process efficiency, but also logs data for aggregation showing faults and transient events historically. This, in turn, enables prediction of future performance and devising of preventative maintenance schemes for maximum up-time.

Reporting of loading on power supplies could also be used as an indication of energy usage and at what time, providing valuable information regarding load leveling and cost savings. On top of that, digitally controlled power supplies could replace dedicated laboratory programmable power supplies in automated test for further cost savings or to power equipment burn-in, where automated “margining” of supply voltages is easily programmed.

Although the typical communications interface to a DSP chip would be I2C using PMBus commands, digital power supplies also often include RS-232/RS-485 and DeviceNet/EtherCAT interfaces more suitable to the industrial environment.

Typically, power-supply vendors will provide a hardware and graphical user interface (GUI) for easy setup of the power supply and monitoring of its performance (Fig. 4).

Standalone Applications

Digital control of power supplies can still benefit applications that don’t require external communications and dynamic adjustment of performance doesn’t bring any advantage. Potentially, power-supply vendors can offer a solution, digitally configured from a standard platform, that would otherwise have to be a custom product, saving the user time and extensive qualification and safety certification costs. If the end application does change, due to, say, a product upgrade, it may be possible to reconfigure the power supply with a simple firmware change through the communications interface, again saving considerable cost and extending the useful life of the supply.

To summarize, although analog control will still have its place for simple and low-power applications, digitally controlled power supplies, particularly at higher power, enable many benefits: increased functionality and flexibility with potential cost savings from reduced energy consumption in larger integrated systems plus extended product lifetime.

Gary Bocock is Technical Director at XP Power.