Current sensors based on the well-known Hall effect are widely used in industrial applications, including motor and load control, inverter and H-bridge current measurements, power factor correction (PFC), overcurrent protection, and general dc and ac power due to their relative ruggedness, range, and ease of use. However, as with most sensors, they do suffer drift due temperature changes, aging, and other factors, and thus may require regular calibration or compensation.

Texas Instruments maintains that its two new Hall-effect sensors overcome these problems with very low drift (they call it “zero drift,” and while its very, very low, it’s not actually “zero,” of course) and other desirable attributes. The ultra-high accuracy of the TMCS1100 (1% maximum error) and TMCS1101 (1.5% maximum error) can minimize or even eliminate the need for costly, disruptive device recalibration and associated shutdown (Fig. 1).

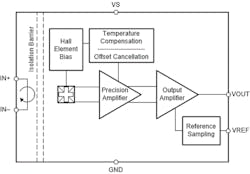

Their analog output voltage is proportional to the input current with four available fixed gains of 50, 100, 200, and 400 mV/A, depending on model suffix. This fixed sensitivity enables operation from a single 3- to 5.5-V power supply, eliminates ratiometric errors, and improves supply-noise rejection. The TMCS1100 and similar TMCS1101 provide current sensing along with 3 kVrms of galvanic isolation, a benefit in some designs but very much an absolute necessity in many others.

With total sensitivity drift over temperature of 0.45% (maximum), one-third of comparable magnetic current sensors, and a maximum full-scale offset drift is under 0.1%, the devices offer the highest measurement accuracy and reliability across a wide range of current. Furthermore, a 0.5% lifetime sensitivity drift (which is at least 50% better than other magnetic current sensors) significantly reduces the performance degradation associated with system aging over time. The sensors provide typical linearity of 0.05%, minimizing signal distortion and helping maintain accuracy across the extended industrial temperature range (−40 to 125°C).

There’s a slight functional difference between the two devices. The TMCS1100 requires an external voltage reference for differential measurement, enabling engineers to optimize their design to meet the most stringent performance goals. The TMCS1101, however, integrates the voltage reference, providing high performance in a pin-to-pin industry-standard implementation to simplify designs while reducing total cost. In addition, some of the accuracy-related specifications of the TMCS1101 are slightly reduced compared to the TMCS1100.

Other key attributes include a robust 600-V lifetime working voltage (dielectric deterioration is the concern here), which is up to 40% higher than competitive devices in the same package, bidirectional and unidirectional current sensing, and a signal bandwidth of 80 kHz. The devices have been rigorously tested beyond industry-standard UL and VDE requirements for greater design margin and device lifetime. Anticipated safety-related certifications include listing by the UL 1577 Component Recognition Program with 60-second isolation and IEC/CB 62368-1 approval.

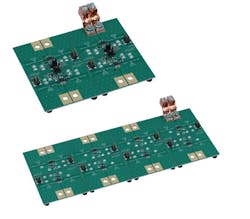

Both Hall-effect current sensors come in 4.90- × 3.90-mm SOIC-8 packages and are priced at $1.50 in 1,000-unit quantities. Also, TMCS1100EVM and TMCS1101EVM evaluation modules (Fig. 2) are available for $59.00 each. These modules allow the user to drive the maximum operating current through the Hall-input side while measuring the isolated output. Each module consists of a single PCB that can be broken into four individual pieces to enable evaluation of the different device variants.

The detailed 50-page datasheets for the TMCS1100 and TMCS1101 include numerous performance graphs, applications information, and error analysis. TI also has an informative white paper “Improving Performance in High-Voltage Systems With Zero-Drift Hall-Effect Current Sensing” and application note SBOA340 “Enabling Precision Current Sensing Designs with Non-Ratiometric Magnetic Current Sensors,” as well as some directly relevant discussion forums that further discuss ratings and applications.