Secondary (rechargeable) battery cells get lots of attention these days (as they should), but many applications still use primary (non-rechargeable) batteries due to installation and siting realities. These include remote industrial sensors (as well as meters and alarms), asset trackers, electronic door locks, keep-alive supplies, and battery-backup arrangements, where the ability to recharge batteries directly or via harvesting is impractical.

As a result, it’s often critical to accurately know the state of health (SoH) of the battery with accuracy so that appropriate actions can be taken when the battery runs low, such as setting an alarm or indicator. The problem is that measuring the SoH with the needed accuracy isn’t easy in practice.

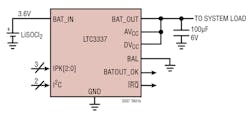

To address this problem, Analog Devices introduced the LTC3337, a primary-battery SoH monitor IC with a precision coulomb counter (Fig. 1). It’s designed to count over an input-voltage range of 1.8 to 5.5 V (e.g., from a single LiSOCl2 cell or two to three alkaline cells) with just 100-nA quiescent current. In basic terms, it monitors the accumulated charge that’s transferred from a primary battery connected to its BAT_IN pin to an output load connected to its BAT_OUT pin.

Editor’s note: In case you’ve forgotten, a coulomb is the SI unit of electric charge, equal to the quantity of charge conveyed in one second by a current of one ampere. Also, it’s nice to see this IC is being called what it is—a “coulomb” counter—rather than use the very misleading slang-like term “gas gauge,” which the industry had been using for a while but at last seems to be fading away from general use. After all, there’s no gas or gasoline in these batteries. Similarly, the somewhat-less incorrect term “fuel gauge” also seems to be shrinking from widespread use. Yes, there’s fuel in the form of electrons, but it is still an awkward designation.

Installation of the LTC3337 is simple enough: It’s connected in series with a primary battery (with minimal associated series voltage drop), and the patented “infinite dynamic range” coulomb counter tallies all accumulated battery discharge. That number is stored in an internal register which is accessed via an I2C interface.

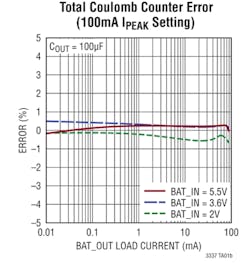

There’s usually a need for more than just delivering a count—an alarm also is needed as the battery is being depleted. When a user-programmable discharge-alarm threshold is reached, the IC generates an interrupt for immediate attention without the need to query it via that I2C connection. Accuracy is needed as well, which is shown by various charts for different ranges (Fig. 2).

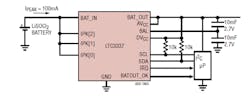

Other features include additional SoH monitoring, which measures and reports (again via I2C interface) the battery voltage, impedance, and temperature. To maintain adequate digital resolution for a wide range of battery capacities and ensure that the LTC3337 can handle a wide range of primary-battery inputs, the peak input-current limit is selectable—via direct package-pin jumpering—in eight steps from 5 to 100 mA. In addition, a “balance” pin is available for applications that use two supercapacitors at the output (Fig. 3).

Finally, there’s something you don’t read too often these days: Despite its ultra-low-current operation, all high-impedance nodes of the LTC3337 are inside the device. Therefore, no special layout precautions are required. The comprehensive 24-page datasheet provides details on internal functionality, overall operation, specifications and error bands, and application-interconnection examples. Housed in a 12-lead, 2- × 2-mm LFCSP package and rated for operation from −40 to 125°C, the LTC3337 is priced at $1.67 (1000 pieces).