This article is part of the Power Management Series: Delving Into Power Density

Members can download this article in PDF format.

What you'll learn:

- Ways to achieve efficient power-density solutions.

- How hardware acceleration comes into play in data-center operations.

- The physical aspect of dealing with floor space.

- How GaN options can significantly improve efficiency.

Data centers keep the internet running 24/7. Approximately 44 zettabytes of data in our data centers come from 8 to 30 billion connected devices worldwide. Forecast experts expect that to increase by 10% over the next year. Thus, power-supply design economics changes are in process.

Modern central processing units (CPUs) in the data center are power-hungry, making it difficult to juggle the balance between power and space. In turn, power density in data centers has risen dramatically. In the first decade of the new millennium, data-center power density was in the region of 4 to 5 kW/rack. Today, we’ve reached 8 to 10 kW/rack heading toward 20 kW/rack (Fig. 1). This also means more heat and added cooling costs.

DC Power in Data Centers

In 2016, Google announced the 48-V dc data-center rack. It reduced energy losses by more than 30% as compared to the previous 12-V systems. This also reduced the Global Cloud Electricity Footprint.

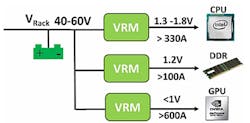

Why have a 48-V power architecture? The 48-V power system supports higher power, has lower distribution losses and less voltage drop (a reduction of 16X I2R losses), higher efficiency, and a safe voltage of 48 V. Plus it has a cost-effective in-rack uninterruptible power system (UPS) and there’s an existing 48-V telecom ecosystem (Fig. 2).

Hardware Accelerators

One unique facet of the data center that’s rarely discussed is the hardware accelerator. Hardware acceleration helps to enable artificial intelligence, including special functionalities like machine learning (ML), brain simulation, and neural engines. This represents the future of data centers whose computer systems learn from data without having to be programmed. Hardware accelerators leverage advanced processors such as field-programmable gate arrays (FPGAs), application-specific integrated circuits (ASICs), systems-on-chip (SoCs) and graphics processing units (GPUs).

Point-of-load (PoL) dc-dc converters with integrated MOSFETs are used to power data-center hardware accelerators.3 These converters, which operate best on a 5- or 12-V input bus, provide high efficiency with good thermal performance.

Another excellent feature of PoL dc-dc converters is adaptive voltage scaling (AVS)—it makes it possible to modify the supply voltage for a processor. In hardware-accelerator applications, the processor can instruct the dc-dc converter to increase or decrease its supply voltage to enable optimum performance. When the supply voltage is reduced, it also reduces processor power consumption.

More Power/Less Board Space

Highly integrated step-down or buck converters can also effectively power digital loads (e.g., FPGAs and processors), improving power density. By limiting pinout, designers are able to save space beyond just the footprint of the IC. These converters also actively reduce the external component count.

Designers should choose a converter series that has device-to-device variants for different options like a power-good pin or an adjustable soft-start pin. This will help optimize a design solution size4 and improve power density.

Data-Center Power Density

As deep learning grows in the industry, data-center power density becomes even more of a main focus. Data centers are creating new business opportunities for specialized cloud services, hosted in facilities that can support more than 30 kW/rack. Power-conversion architecture solutions6 that can improve density in the data center by making systems more energy efficient will be in great demand.

More data-center designs use power-hungry CPUs and FPGAs that must fit within a particular rack-unit form factor without extending the board size. Power modules will optimize the power-supply layout to fit a small area near the point of load, which is usually a high-powered processor. Technologies like raised inductors and embedded components will enable power modules to occupy a smaller x-y board area as compared to a similar converter or controller with an external MOSFET design.

Buck controllers are potentially good options in the data center since their performance-to-cost ratio is excellent. These controllers usually cost much less than converters and power modules, especially if they operate at higher currents to drive power-hungry processor loads. Even when including the cost of the external MOSFETs, total solution cost will probably be lower than a converter or power-module solution.

Floor Space and Power Density

The historic method of specifying data-center power density, using a single number of watts/square foot (or watts/square meter), is an unfortunate and outdated practice that has caused unnecessary confusion as well as waste of energy and money. The typical methods used to select and specify power density are flawed, and an improved approach is needed for establishing space requirements, including recommended density specifications for typical situations (Fig. 3).

If we specify too low a power density, performance becomes unpredictable with various overload and overheating problems occurring. Specifying too high a power density needlessly increases cost and operating expenses (see Reference 5).

Reference 5 provides a new approach to the specification of space requirements and power density with the following four key features:

The unit of physical space, in the density specification, is the IT cabinet—NOT floor area. Floor area is determined, during the design, as an output of the process using per cabinet power and other factors.

The specification is hierarchical and modular so that different rooms and zones can have different density requirements.

The specification comprehends that Information Technology (IT) cabinets within data centers have different power requirements, and that these requirements may not be well-defined in advance.

The specification comprehends that IT equipment cabinets may have power requirements that vary with time.

The industry is seeing the key power-supply metric shifting from dollars-per-watt to dollars-per-density. While a data center’s power density is specified by a single number, such as W/ft2 or W/m2, many important performance characteristics are not defined5. All told, though, rack density in the data center is continuously on the rise (Fig. 4).

Cut Power-Conversion Losses Virtually in Half with GaN

Gallium-nitride (GaN) devices improve data-center power density and virtually “halve power losses” when used instead of their silicon brethren. Data-center power supplies, based on silicon MOSFETs, are being replaced with GaN transistor-based designs, which will more easily achieve higher operating efficiency. Incrementally, GaN-based power supplies can deliver 2X the power in the same size, or the same power in half the size.

GaN devices promise extreme energy-efficiency improvements in the data center. Replacing silicon as the semiconductor material in power-conversion chips with GaN also enable much smaller devices that provide faster switching.

The radical energy-efficiency improvements promised by GaN power converters on motherboards will lead to more computing power that fits into a single data-center cabinet. This will no doubt make GaN technology appealing to many within the data-center industry.

The following are just two examples of 48-V to 1-V PoL solutions for data-center applications driving processors:

Summary

The amount of power consumed by each data-center rack continues to climb.9,10 The 48-V dc rack, instituted in 2016 by Google, was a big step toward improving power density in the data center. And dc-dc converters made significant data-center efficiency and power-density improvements in terms of hardware accelerators as well as high-speed processors. GaN power switches may be the most significant savior for the data center versus the incumbent silicon MOSFET solutions. Designers are beginning to see the value of GaN for dc-dc converters that can deliver efficient power to data centers. Focusing on low-voltage power is essential in information processing.

The data center’s future looks brighter with the design efforts mentioned in this article. More new and innovative power design architectures will be developed as power engineers strive for even better power-density numbers moving forward.

References

2. Data centers are more energy efficient than ever

3. DC/DC Converter Solutions for Hardware Accelerators in Data Center Applications

5. Calculating Space and Power Density Requirements for Data Centers

6. Power Solution Options for Data Center Applications

7. Two-Stage 48-V VRM With Intermediate Bus Voltage Optimization for Data Centers

9. Rack Density Keeps Rising at Enterprise Data Centers

10. Report: Data Center Rack Density is Rising, and Heading Higher